Translation clamshell test fixture

A test fixture and clamshell technology, which is applied in the field of translation clamshell test fixtures, can solve the problems of affecting the erection of display instruments on the production line, affecting the test pass rate, and high height, so as to improve the test pass rate, eliminate vibration, and reduce height. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

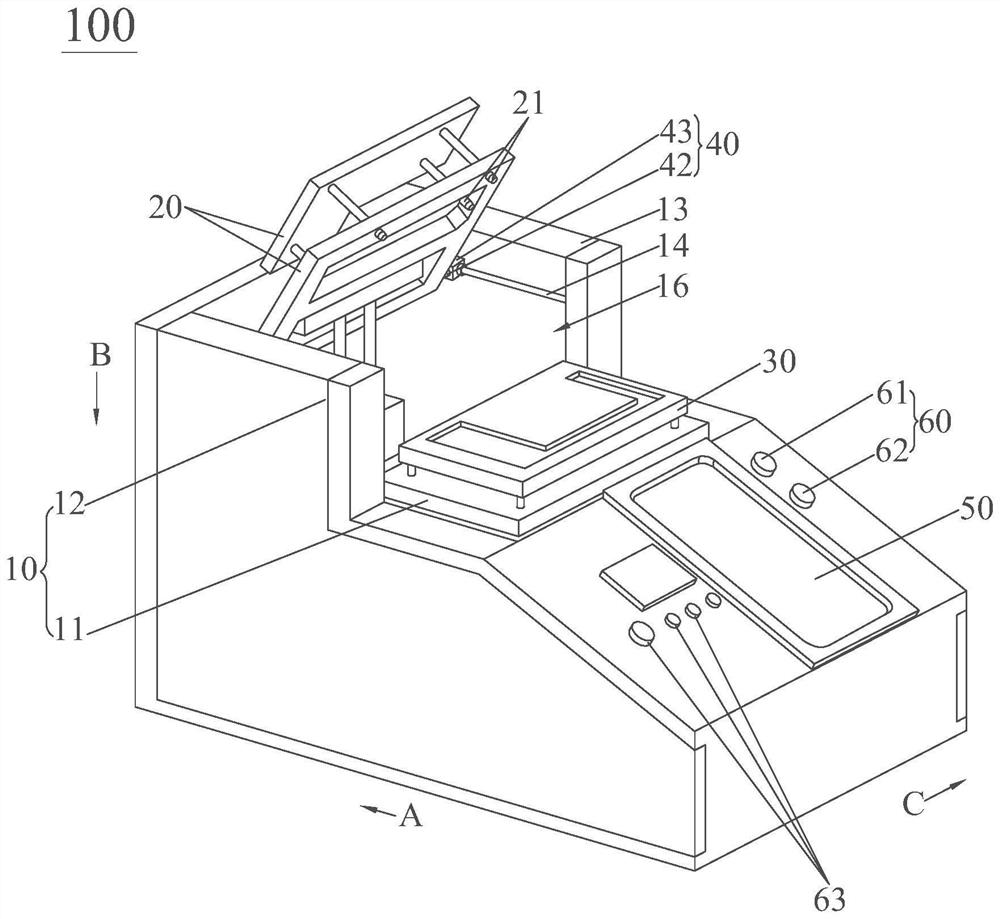

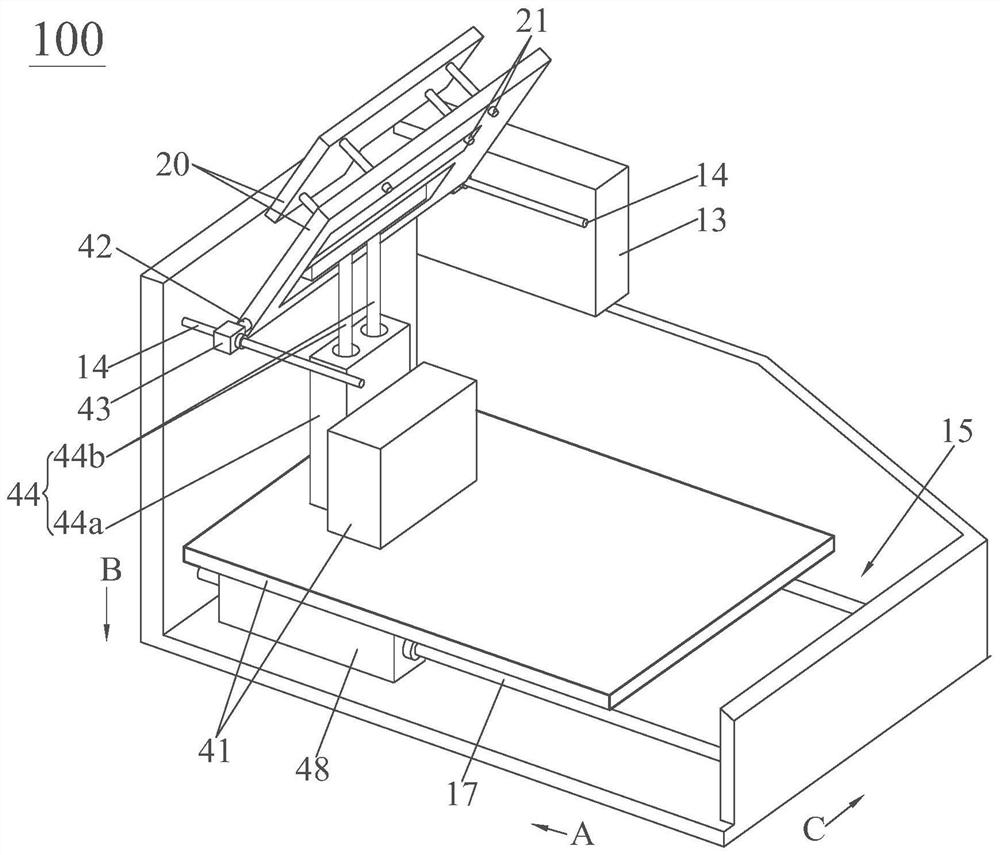

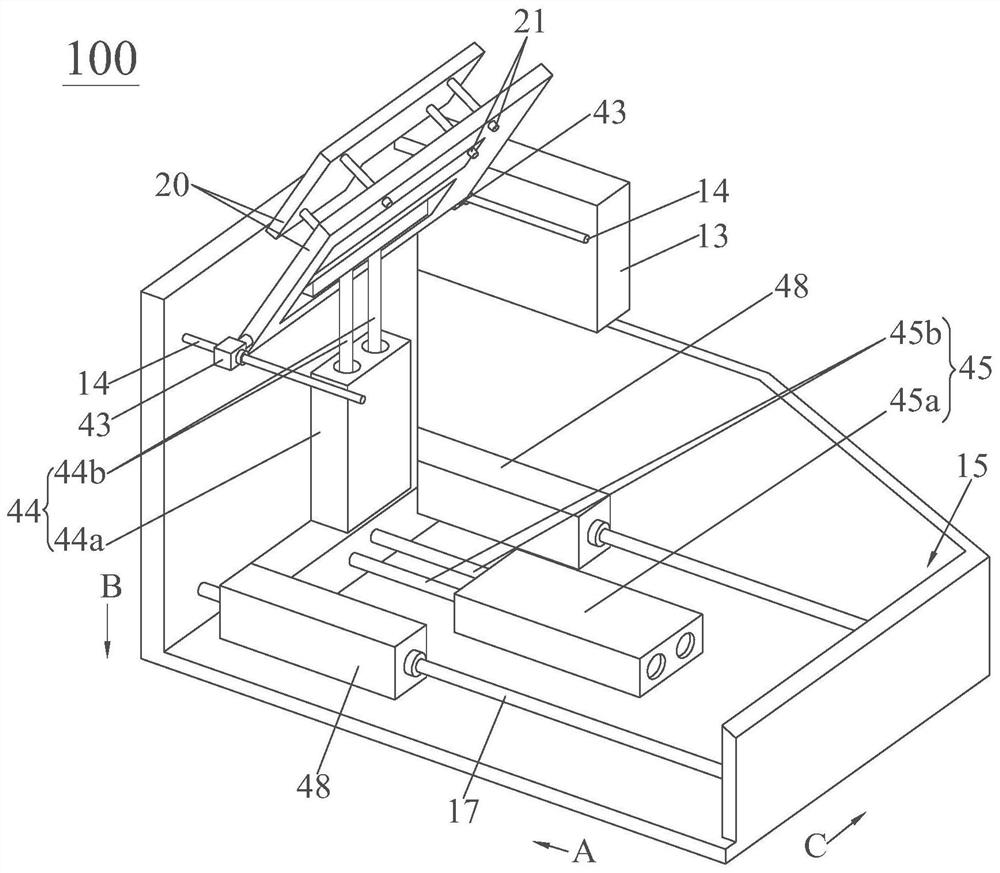

[0022] In order to describe the technical content, structural features, and achieved effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0023] see Figure 1 to Figure 3 , The translation flip-type test fixture 100 of the present invention includes a fixture frame body 10 , an upper splint body 20 , a lower splint body 30 located below the upper splint body 20 , and a translation and flip driving mechanism 40 assembled on the fixture frame body 10 . The lower splint body 30 is installed on the fixture frame body 10, so that the lower splint body 30 and the fixture frame body 10 are fixed together; the lower splint body 30 and the upper splint body 20 both have test pins 21, of course, according to actual needs, it can also be made by Either the lower splint body 30 or the upper splint body 20 has the test pin 21 , so it is not limited thereto. The upper splint body 20 is assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com