Detection mechanism and detection device

A detection mechanism and detection device technology, applied in the fields of semiconductor/solid-state device testing/measurement, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems of high cost and low detection efficiency, so as to reduce the detection cost and improve the detection effect. , clear imaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

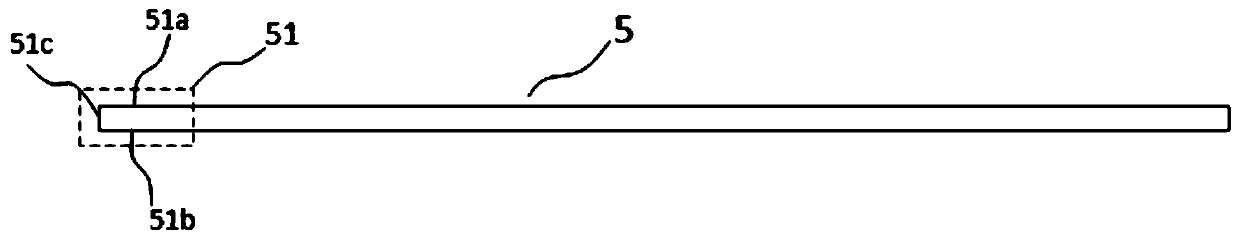

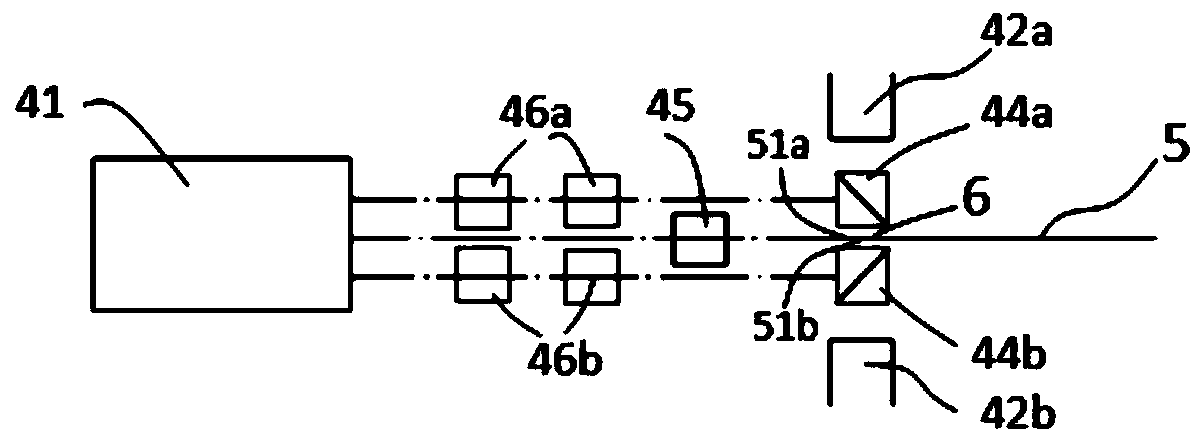

[0048] like figure 2 , image 3 As shown, the plane where the detection station 6 mentioned in this embodiment is located is parallel to the horizontal plane. Correspondingly, the silicon wafer 5 to be tested located at the detection station 6 is also in a horizontal state, the first surface of the tested edge 51 of the silicon wafer 5 to be tested is the upper surface 51a, and the second surface of the silicon wafer 5 to be tested is the lower surface 51b.

[0049] The surface light source includes an upper surface light source 42a and a lower surface light source 42b, and the surface reflection mechanism includes an upper surface reflection mechanism 44a and a lower surface reflection mechanism 44b. in:

[0050] The upper surface light source 42a is located above the detection station 6, the upper surface light source 42a is configured to emit upper surface irradiation light to the upper surface 51a of the edge to be tested 51, and the upper surface reflection mechanism ...

no. 2 example

[0065] like Figure 4 As shown, the structure of the detection mechanism provided in this embodiment is basically the same as that of the detection mechanism in the first embodiment. The only difference between the two is that in the first embodiment, the first cylindrical lens 46 a and the second cylindrical lens 46 b are arranged close to the detection camera 41 . However, in this embodiment, the first cylindrical lens 46 a and the second cylindrical lens 46 b are arranged close to the detection station 6 .

no. 3 example

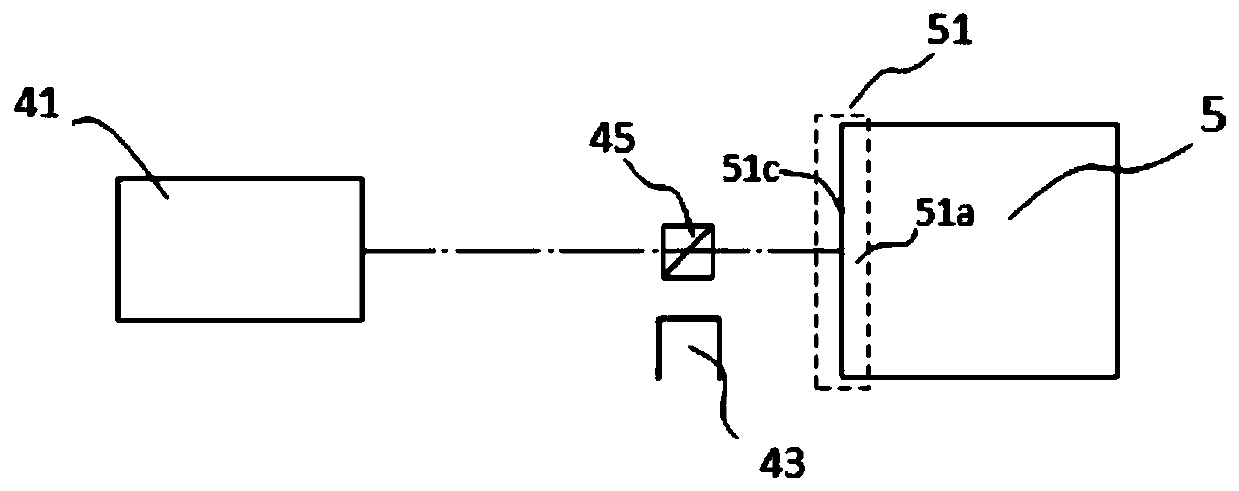

[0067] like Figure 5 As shown, the structure of the detection mechanism provided in this embodiment is basically the same as that of the detection mechanism in the first embodiment. The only difference between the two is that in the first embodiment, the number of the first cylindrical lens 46 a and the number of the second cylindrical lens 46 b are both two. However, in this embodiment, the number of the first cylindrical lens 46a and the second cylindrical lens 46b is one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com