Polyorganosiloxane release coating and method for its preparation and use

A polyorganosiloxane, release coating technology, applied in coatings, chemical instruments and methods, layered products, etc., can solve problems such as coating migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

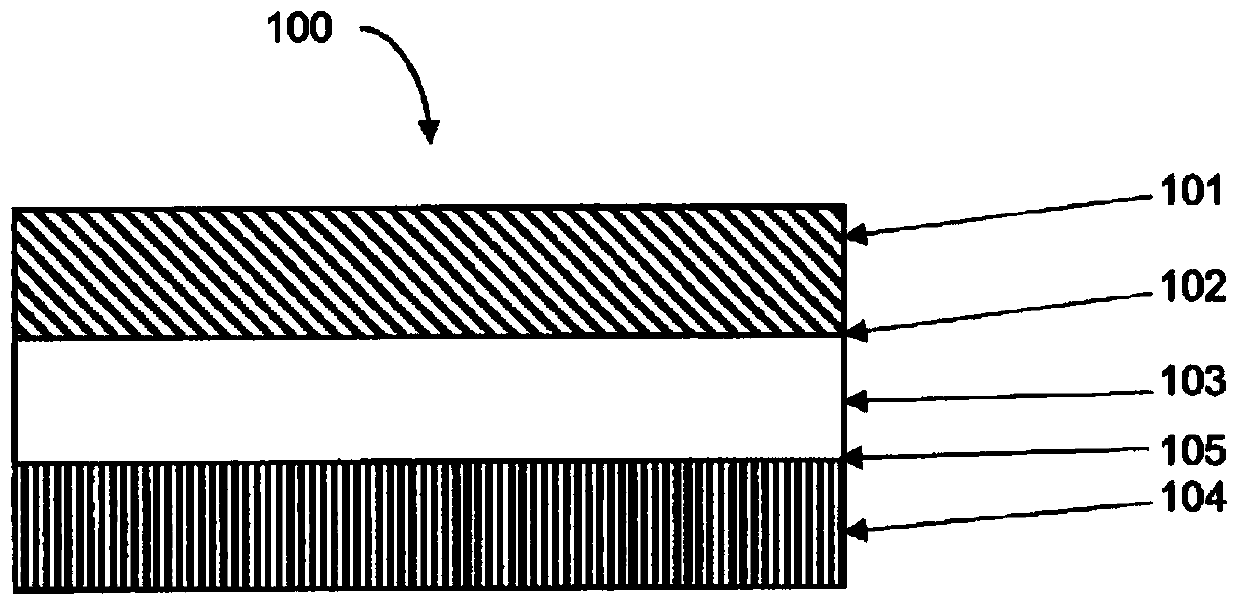

Image

Examples

example

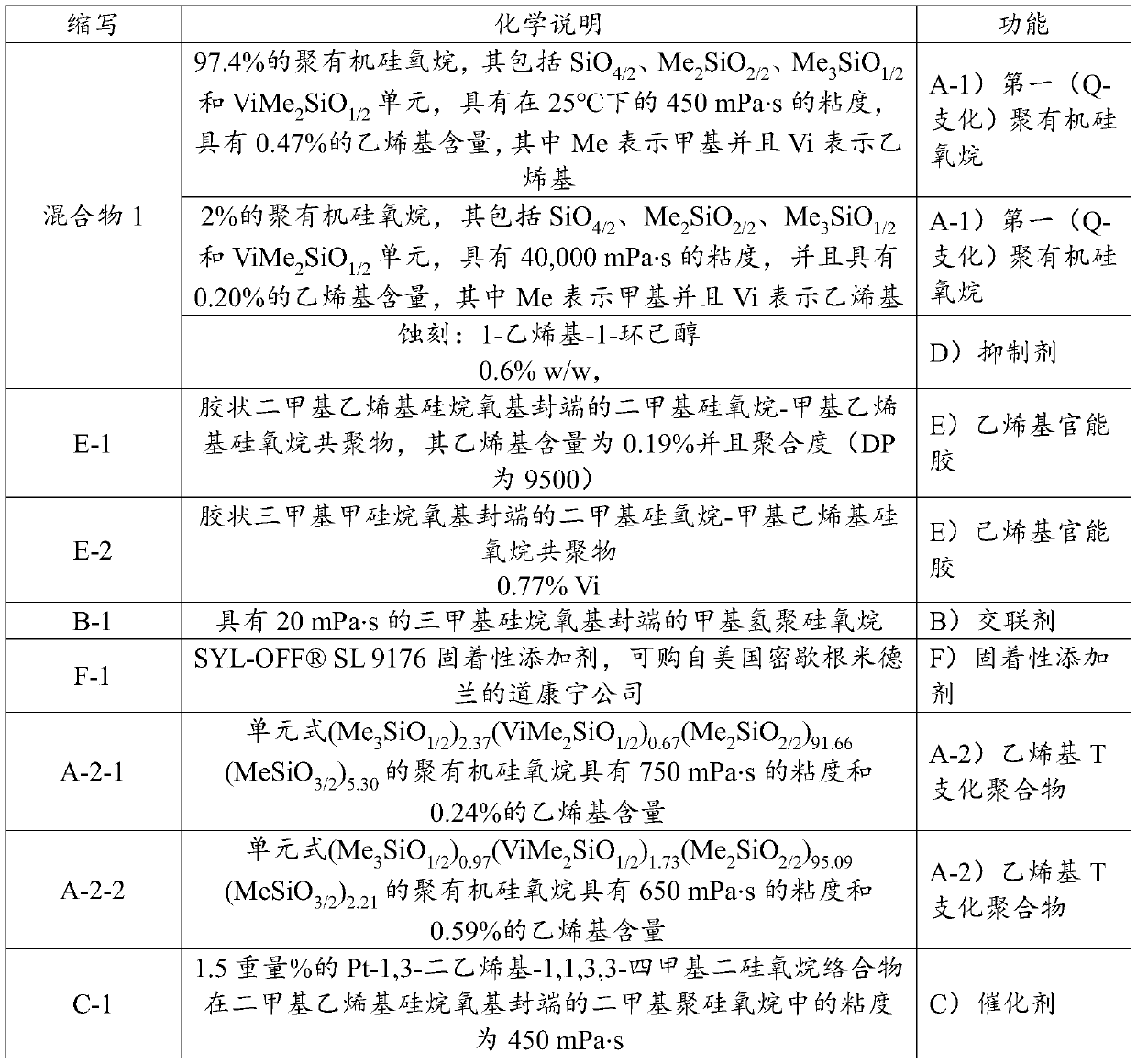

[0090] These examples are intended to illustrate some embodiments of the invention to those skilled in the art and should not be construed as limiting the scope of the invention set forth in the claims. The following abbreviations are used: RF: release force (peel tester), CW: coating weight (Oxford XRF), RO: rub off (fix performance) and SAS: subsequent adhesion strength (migration performance).

[0091] RT: room temperature of 25°C. Table 1 below shows the starting materials used in these examples. Viscosities are measured at 25°C unless otherwise stated.

[0092] Table 1 - Starting materials for the examples

[0093]

[0094] Reference example 1-release coating preparation

[0095] Release coating composition samples were prepared by the following steps I. and II., using the starting materials and amounts indicated in the respective tables.

[0096] I. Add the following starting materials to a beaker: Mixture 1 (and one or more of A-2-1, A-2-2, E-1, and E-2, if prese...

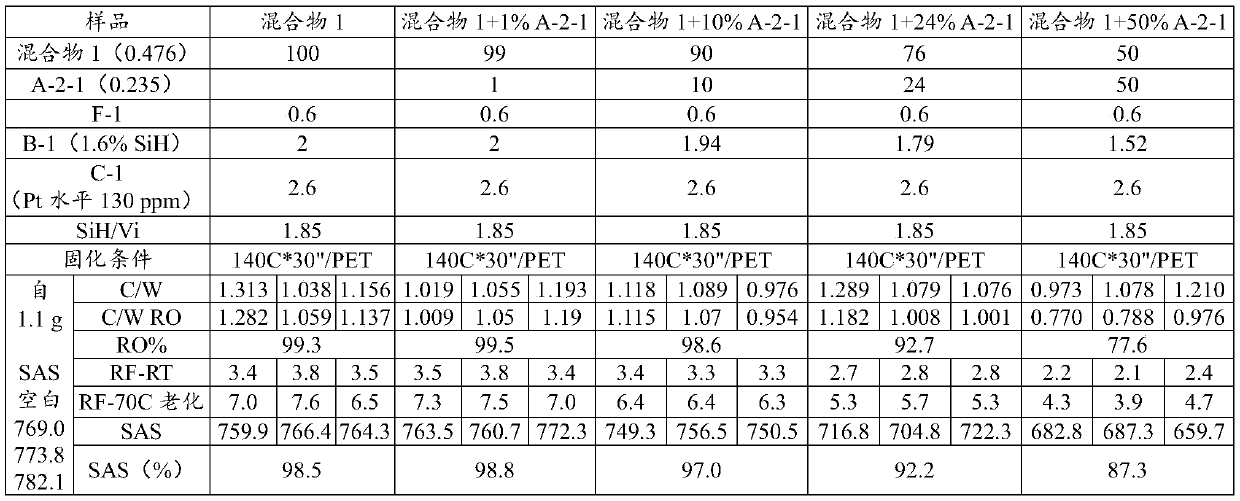

example 1

[0108]

[0109] This example shows that adding more vinyl functional silsesquioxane A-2-1 shows lower RF and lower SAS. A SAS with 50% A-2-1 in the system still shows a good SAS because the SAS is above 85%. This example shows the benefit of using the release coating composition of the present invention to obtain a room temperature release force of less than 3 grams on a PET substrate.

example 2

[0111]

[0112] This example shows the release force reduction effect as the amount of vinyl functional silsesquioxane A-2-2 increases, and when increasing the amount of A-2-2 added to the release coating composition The release force and SAS remain stable when the amount is constant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com