Liquid storage core and preparation method thereof

A liquid storage and core technology, applied in the field of liquid storage core and its preparation, can solve the problems of limited application field, poor air permeability, compression resistance and deformation resistance, use, etc., and achieve simple preparation method, low cost, and easy The effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

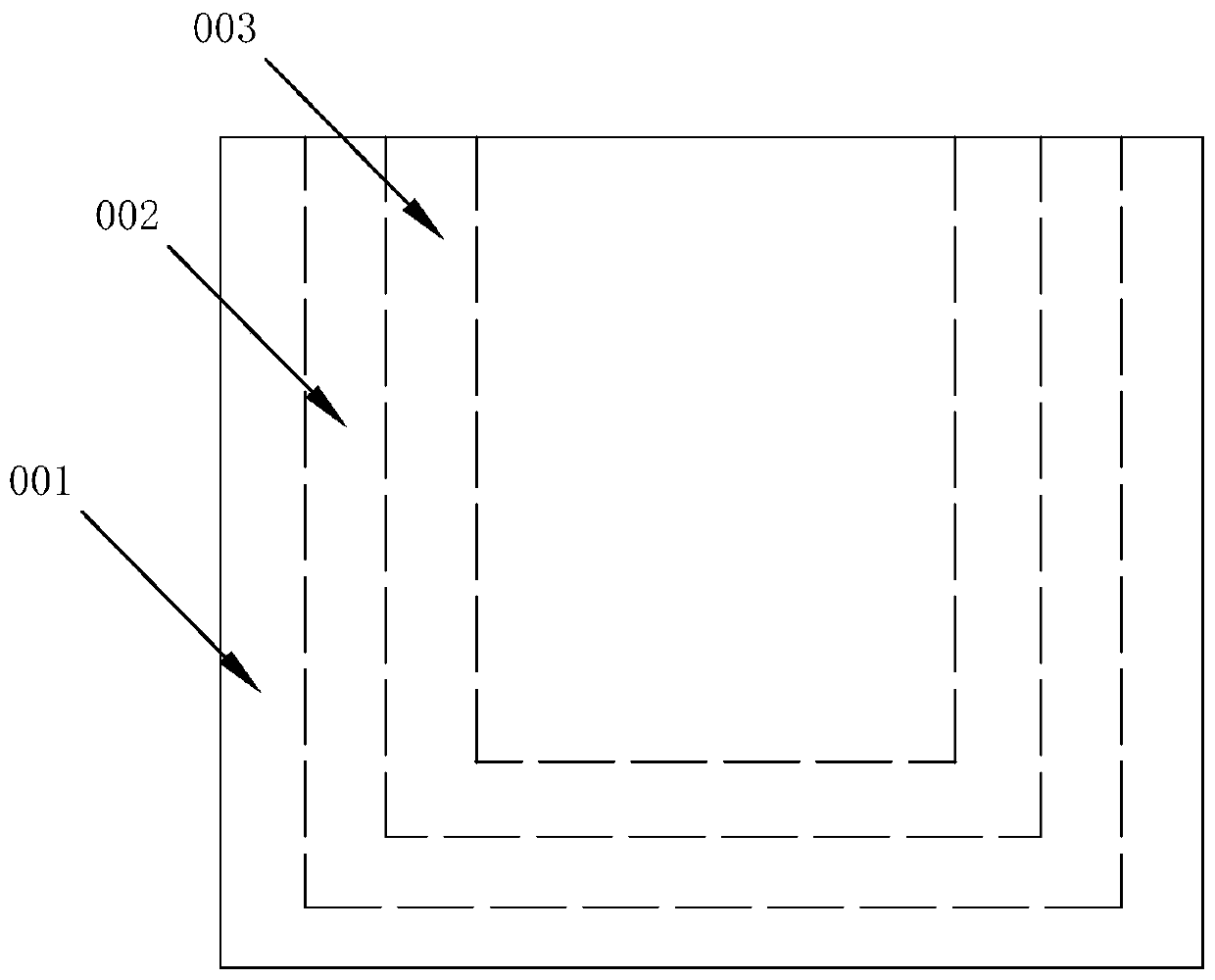

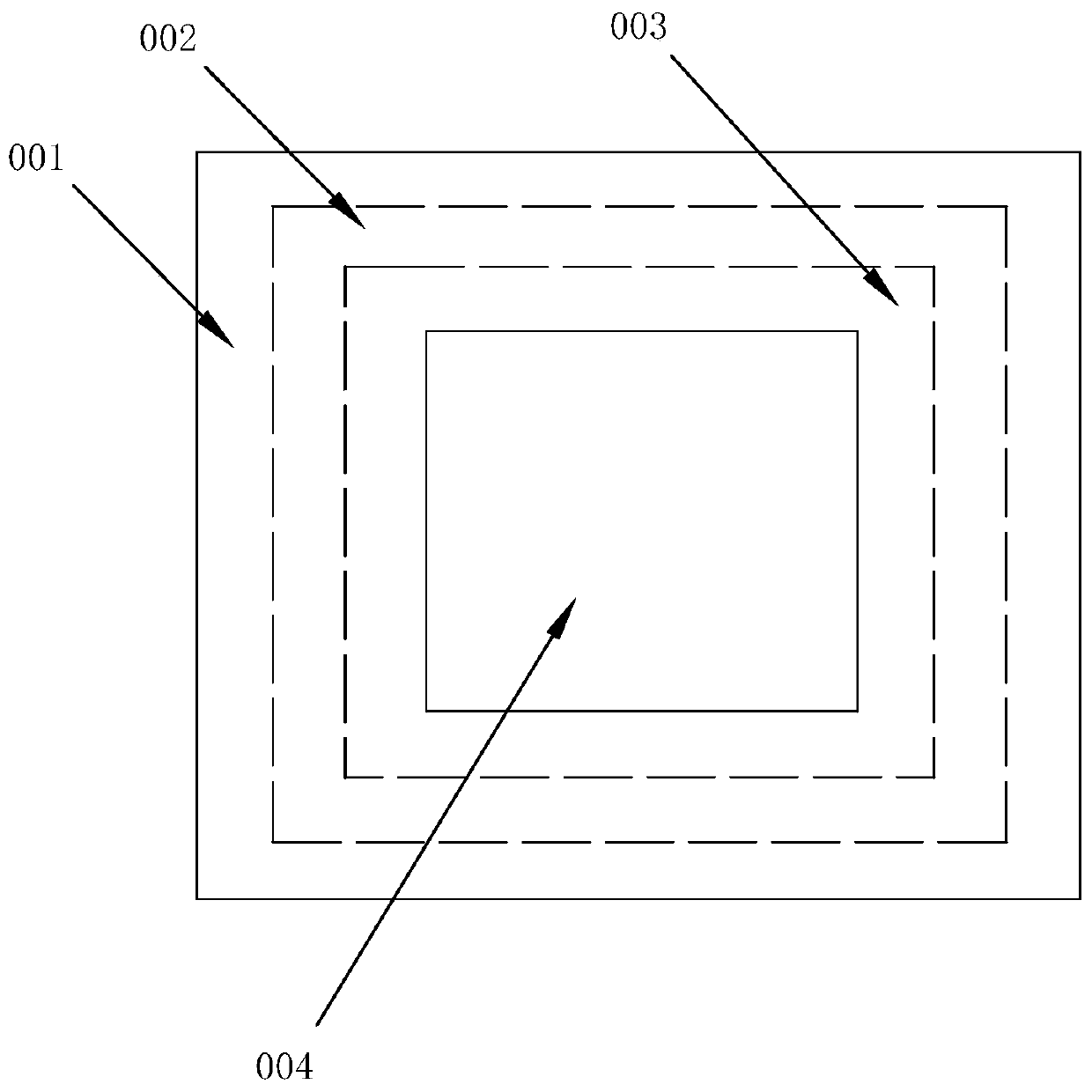

Embodiment 1

[0024] The sponge with a porous three-dimensional structure is used as the matrix. The size of the sponge is 20 cm (length) * 20 cm (width) * 20 cm (height). The central part of the sponge is relatively large, and the external void is relatively small. Immerse the sponge as a whole in the polyurethane hydrophilic finishing agent for 1 minute, take it out, pad and dry it, and the sponge will have a hydrophilic function.

[0025] Then immerse the five sides of the sponge body in a 5 cm deep silicone water-repellent finishing solution for 1 minute, take it out and put it in an oven at 130°C for 3 minutes, and keep the water-repellent finishing sponge during the drying process The droplet contact angle on the body surface is greater than 110 degrees.

[0026] Then immerse the five surfaces after water-repellent finishing in the silicone water-repellent finishing solution 3 cm deep for 1 minute, take it out, and put it in an oven at 140°C for 3 minutes to dry. The droplet contact ...

Embodiment 2

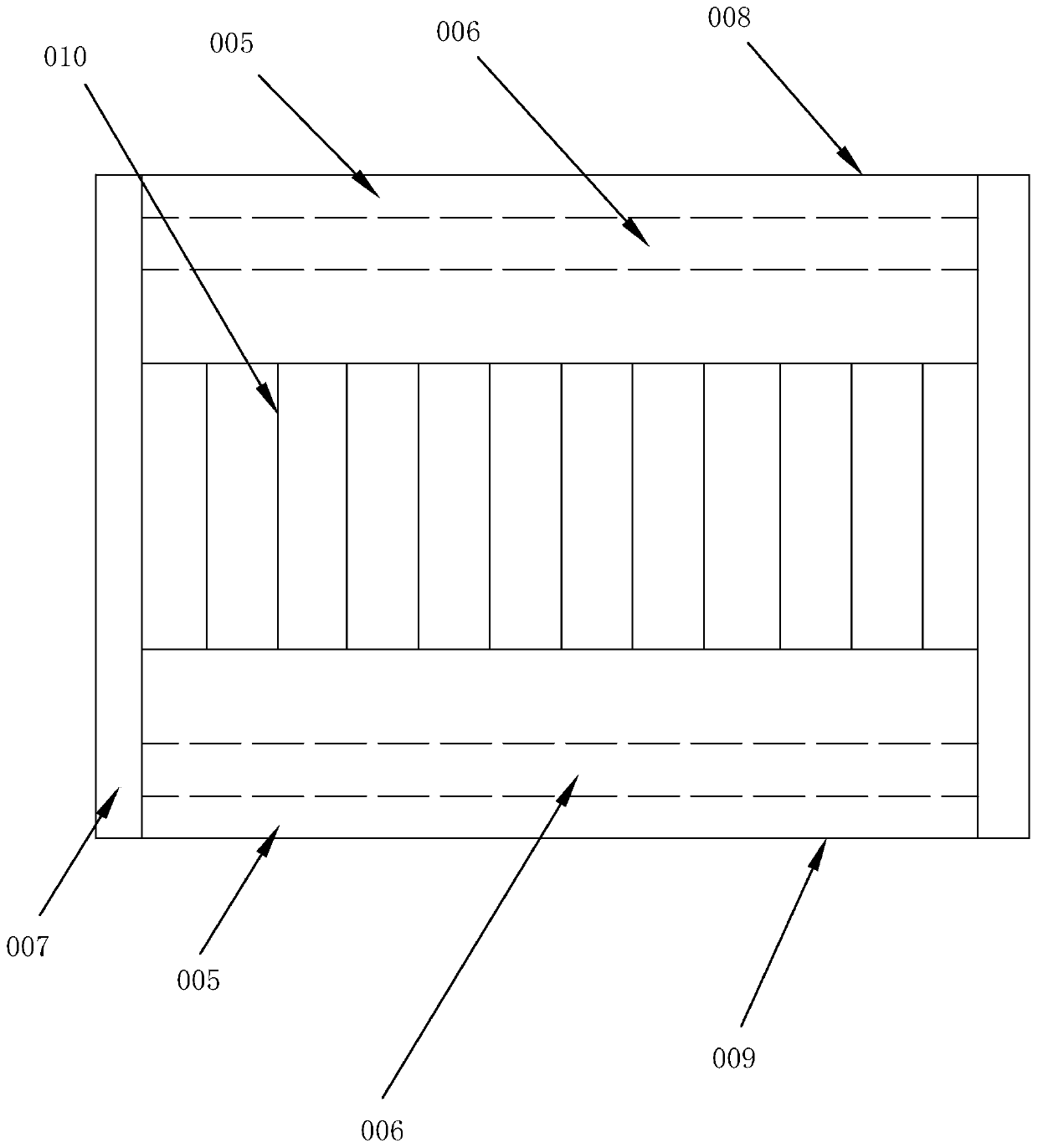

[0030] The multi-space knitted spacer fabric is used as the base, and the size of the multi-space knitted spacer fabric is 20 cm (length) * 10 cm (width) * 0.2 cm (height). The gap of the spacer fabric is relatively large, and the external space is relatively small. The spacer fabric is immersed in the polyurethane hydrophilic finishing agent for 1 minute, and after being taken out, padded and dried, the spacer fabric has a hydrophilic function.

[0031] Then immerse the upper surface of the spacer fabric in a 0.02 cm deep water-repellent finishing agent solution containing paraffin wax for 1 minute, take it out and put it in an oven at 130°C for 3 minutes to dry, and keep the liquid droplets on the upper surface during the drying process The contact angle is greater than 110 degrees; then immerse the lower surface of the spacer fabric in a 0.02 cm deep water-repellent finishing agent solution containing paraffin wax for 1 minute, take it out and put it in an oven at 130°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com