Green magnetization treatment device for medical waste garbage

A magnetization treatment, waste technology, applied in the direction of transportation and packaging, chemical instruments and methods, solid waste removal, etc., can solve the problems of high cost budget, low effect of magnetic separation mechanism, etc., to solve the problem of processing, low cost, The Green Effect of Gas Emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

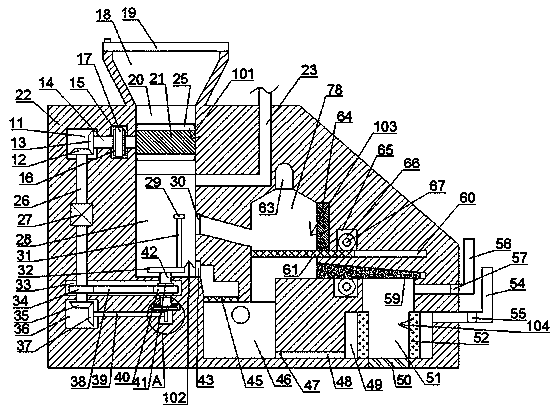

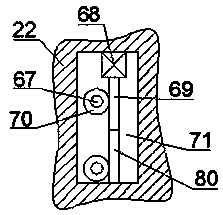

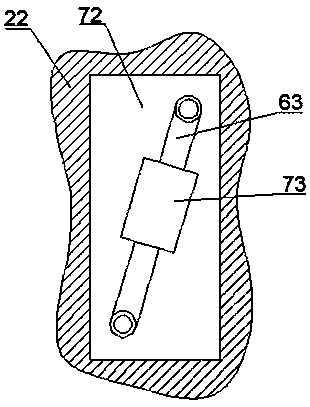

[0019] Combine below Figure 1-5 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0020] refer to Figure 1-5 According to an embodiment of the present invention, a green garbage magnetization treatment device includes a main box body 22, and a crushing chamber 20 is opened in the main box body 22, and an inlet with an upward opening is connected to the upper side of the crushing chamber 20. A feed port 18, a crushing mechanism 101 capable of crushing garbage is provided in the crushing chamber 20, a separation chamber 28 is connected to the lower side of the crushing chamber 20, and water can be passed into the separation chamber 28, and the separation chamber 28 is provided with There is a stirring rod 31, the top surface of the stirring rod 31 is fixed with a top...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap