Construction method for precast outer wall waterproof structure of assembly type concrete building

A waterproof structure and construction method technology, which is applied to building components, building structures, buildings, etc., can solve the difficulty of ensuring the waterproofing of building exterior walls, the difficulty of repairing composite thermal insulation exterior wall panels, and increasing the difficulty of external wall leakage control And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

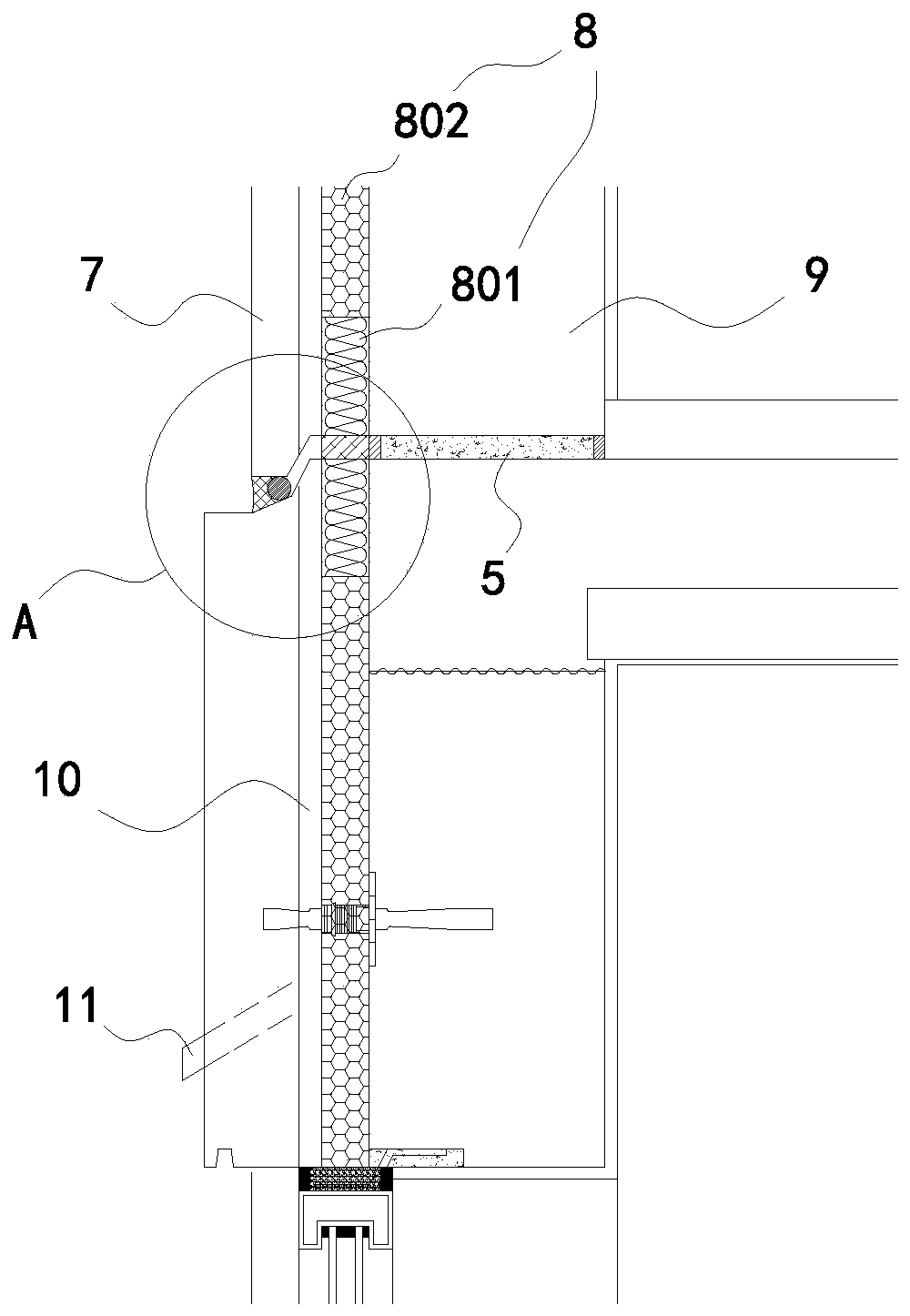

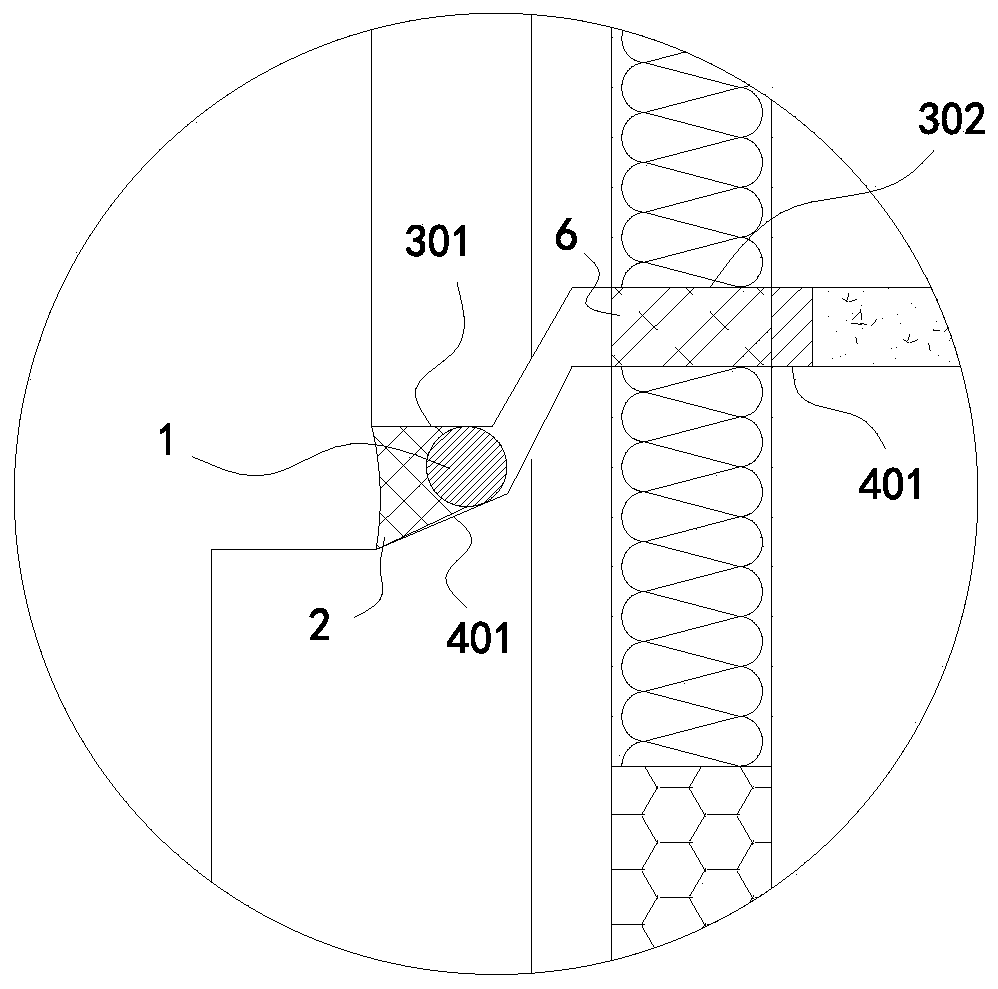

[0052] The present invention will be clearly and completely described below in conjunction with the accompanying drawings. Those skilled in the art will be able to implement the present invention based on these descriptions. in conjunction with figure 1 and 2 Before the present invention is described, it should be pointed out that:

[0053] The technical solutions and technical features provided in each part of the present invention, including the following description, can be combined with each other under the condition of no conflict.

[0054] In addition, the embodiments of the present invention referred to in the following description are generally only a part of the embodiments of the present invention, rather than all the embodiments. Therefore, based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts shall fall within the protection scope of the present invention.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com