tool for building walls

A technology of building walls and tools, which is applied in the field of construction tools, can solve the problems of high requirements for staff, and achieve the effect of reducing experience factors, reducing requirements, and lowering entry barriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

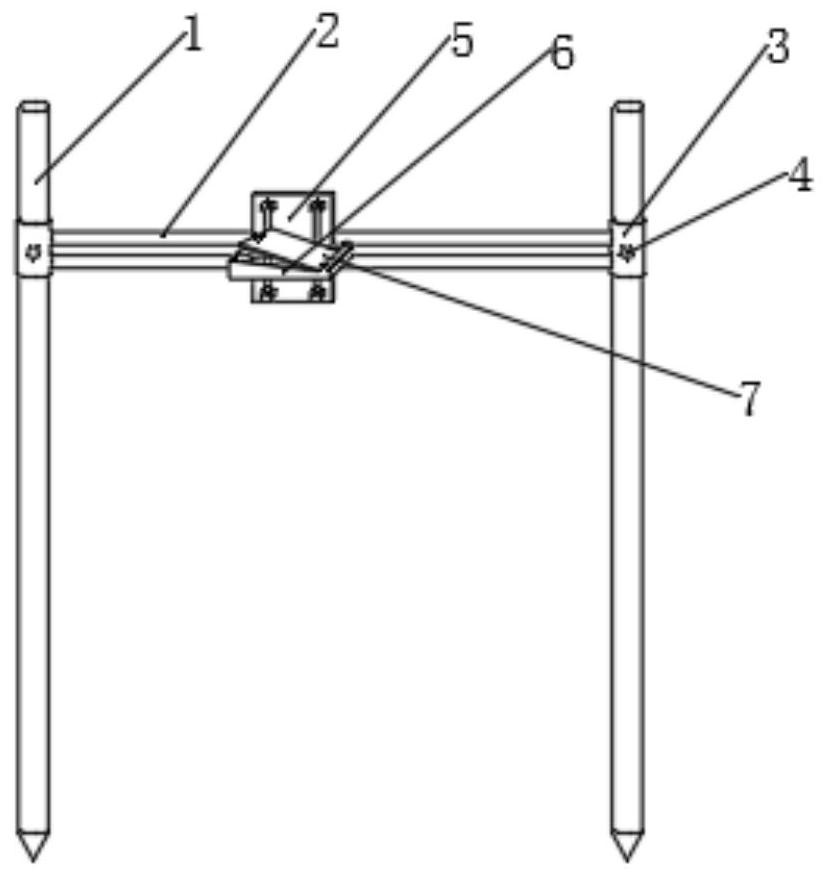

[0025] Depend on figure 1 As shown, a building wall-building tool includes a support bar 1 that plays a vertical guiding role, and a cross bar 2 that plays a horizontal guiding role is slidably connected to the support bar 1. Limited brickwork components;

[0026] Support bar 1 is a vertical slide bar, and support bar 1 is provided with two, and its bottom is provided with the tip that is convenient to support bar 1 fixing, and cross bar 2 is connected on the support bar 1 by cross bar seat 3, and cross bar seat 3 is A circular tube with the same inner diameter as the outer diameter of the support rod 1, the cross bar 2 is fixedly connected with the cross bar seat 3, preferably, in order to facilitate the height of the cross bar 2 during work, the cross bar seat 3 is provided with a handle for fixing the cross bar seat 3 The adjustment screw 4 of the cross bar seat 3 is connected with the adjustment screw 4 by threads;

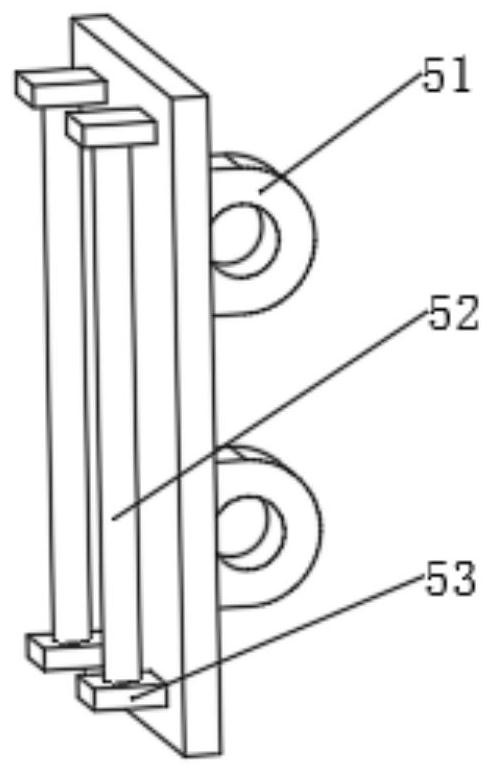

[0027] Preferably, in order to prevent the bricklaying...

Embodiment 2

[0032] Depend on Figure 5 As shown, a building wall-building tool includes a support bar 1 that plays a vertical guiding role, and a cross bar 2 that plays a horizontal guiding role is slidably connected to the support bar 1. Limited brickwork components;

[0033] Preferably, in order to make the support rod 1 vertically fixed, the support rod 1 is also provided with a vertical correction assembly 8, the vertical correction assembly 8 includes a plumb seat 81, a correction seat 82 and a plumb line 83, and the plumb seat 81 is fixed Connected to the top of the support rod 1, the correction seat 82 is movably connected to the support rod 1, the correction seat 82 is connected to the support rod 1 through the height adjustment seat 84, and the correction seat 82 is provided with a calibration point corresponding to the plumb line 83, The height adjustment seat 84 is provided with an adjustment screw 4, and the plumb line 83 is a prior art plumb line. When the support rod 1 was ...

Embodiment 3

[0036] Depend on Figure 5 As shown, a building wall-building tool includes a support bar 1 that plays a vertical guiding role, and a cross bar 2 that plays a horizontal guiding role is slidably connected to the support bar 1. Limited brickwork components;

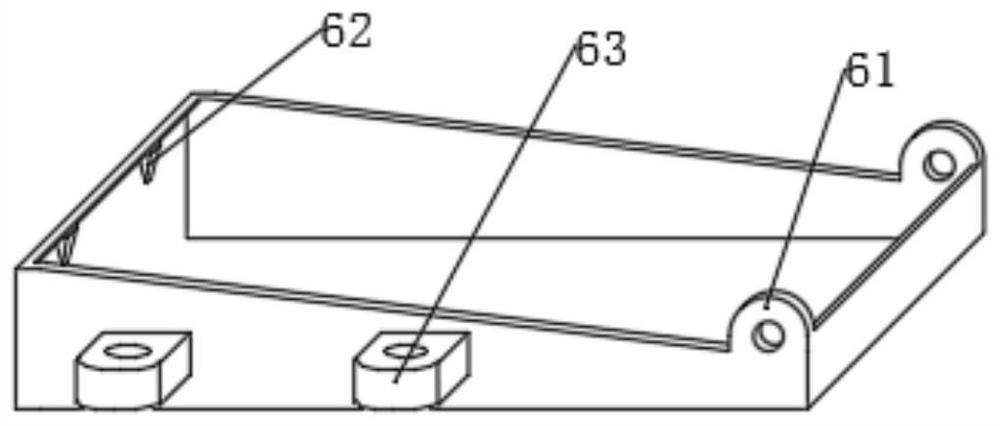

[0037] In this embodiment, in order to improve the efficiency of wall-building, there are two regulating plates 5, limiting frames 6 and mud-pressing plates 7;

[0038] Others are identical with embodiment 2.

[0039] In summary, the working principle of the present invention is:

[0040] Fix the support rod 1 at the position of laying the wall, adjust the vertical angle of the support rod 1 through the vertical correction assembly 8, then adjust the adjustment plate 5, the limit frame 6 and the mud pressing plate 7 to the position of the brick laying, and put the concrete into the In the limit frame 6, use the mud pressing plate 7 to flatten the concrete, then put the bricks into the limit frame 6, use a masonry knife ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com