A High Stability Temperature Sensor Sensitive Element

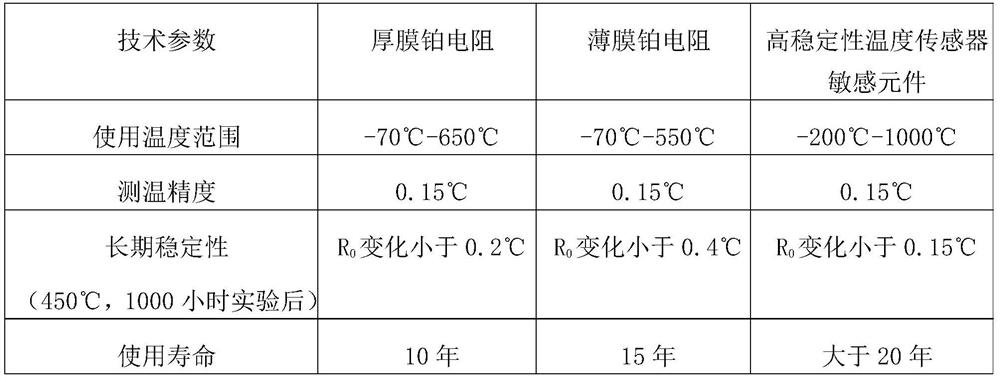

A technology of temperature sensor and sensitive element, used in thermometers, thermometers and instruments using electrical/magnetic elements directly sensitive to heat, etc., can solve the problem of large difference in expansion coefficient between platinum film and ceramic substrate, and unsatisfactory component stability , unstable resistance and other problems, to reduce the transportation process, improve stability, and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

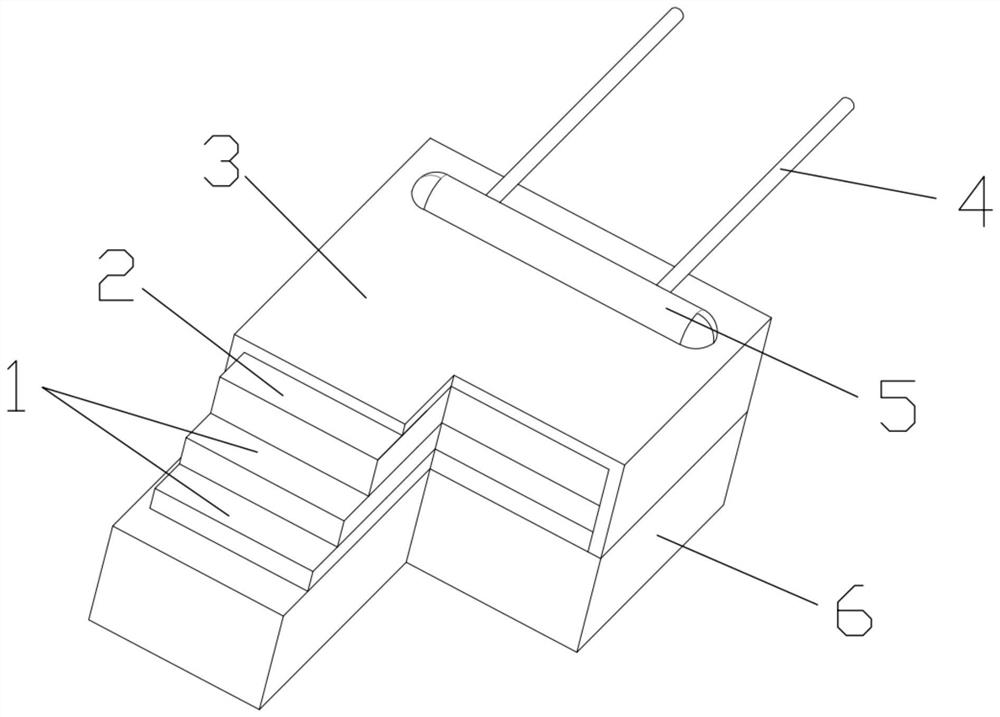

[0034] A high stability temperature sensor sensitive element, as attached figure 1 As shown, it includes a ceramic substrate 6, a thick-film platinum layer 1, a thin-film platinum layer 2 and an insulating encapsulation layer 3. The thick-film platinum layer 1 is arranged on the ceramic substrate 6 by printing and sintering, and the thick-film platinum layer 1 has a network structure. The skeleton is honeycomb-shaped. The thin-film platinum layer 2 is filled in the skeleton by magnetron sputtering, and the thick-film platinum layer 1 and the thin-film platinum layer 2 are etched to form a temperature-sensing circuit. In this embodiment, the temperature-sensing circuit is preferably platinum commonly used in the prior art. Thermal resistance temperature sensing circuit.

[0035] The insulating encapsulation layer 3 wraps the surface of the thick-film platinum layer 1 and the thin-film platinum layer 2 (that is, the surface of the temperature-sensing circuit), the insulating en...

Embodiment 2

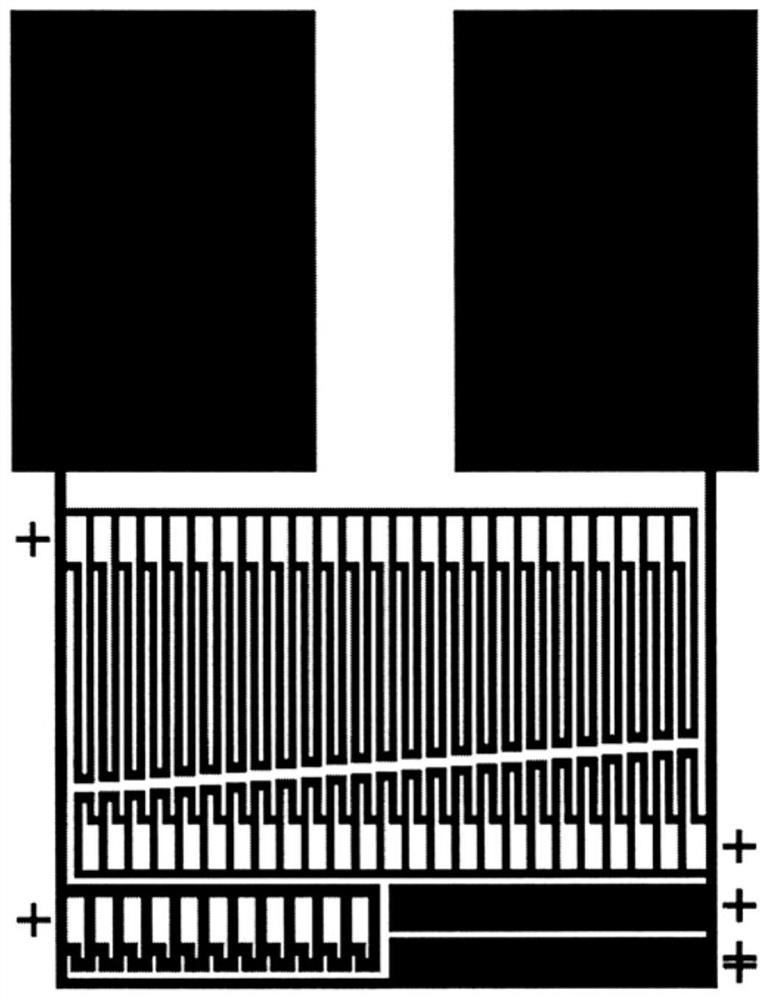

[0041] The difference between this embodiment and Embodiment 1 is that: figure 2 As shown, the temperature sensing circuit includes two ladder circuits, a Link circuit and two wide resistance conductors.

Embodiment 3

[0043] The difference between this embodiment and Embodiment 2 is that a method for manufacturing a high-stability temperature sensor sensitive element is also provided, including the following steps:

[0044] Platinum powder production steps: (1) dissolving step: using aqua regia to dissolve the platinum material to obtain a chloroplatinic acid solution.

[0045] (2) Purification step: Purify the chloroplatinic acid solution by purification technology to obtain ultra-high-purity sodium chloroplatinate. The specific purification steps are as follows: add analytically pure sodium chloride to the chloroplatinic acid solution to obtain a sodium chloroplatinate solution, adjust the pH value of the sodium chloroplatinate solution to 6 with a high-purity sodium hydroxide solution, and let it stand After 30 minutes, the solution was evaporated to dryness, and high-purity sodium chloroplatinate (purity above 99.999%) was obtained through hydrolysis and filtration. Through multiple pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com