Method for evaluating soil corrosion characteristics of buried pipeline

A technology for soil corrosion and buried pipelines, applied in the field of oilfield-related technical analysis, can solve problems such as pitting corrosion/general corrosion rate not being carried out, the characteristics and main influencing factors of soil corrosion on pipelines, and the inability to quantify the corrosion rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

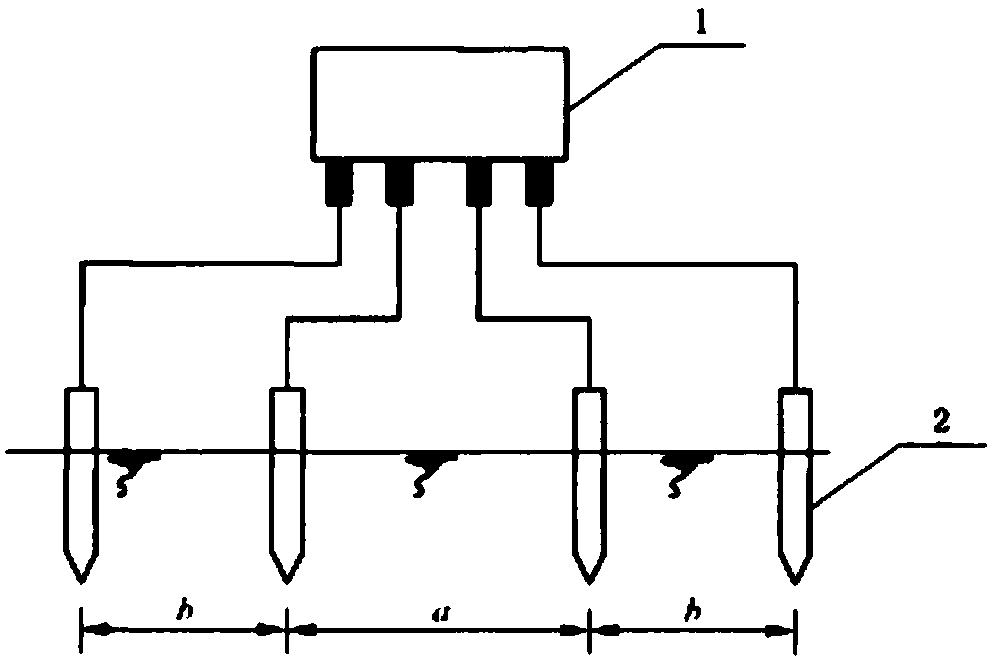

[0061] see Figure 1 to Figure 4, the present invention provides a method for evaluating soil corrosion characteristics of buried pipelines, characterized in that:

[0062] S1. Determine soil corrosion factors;

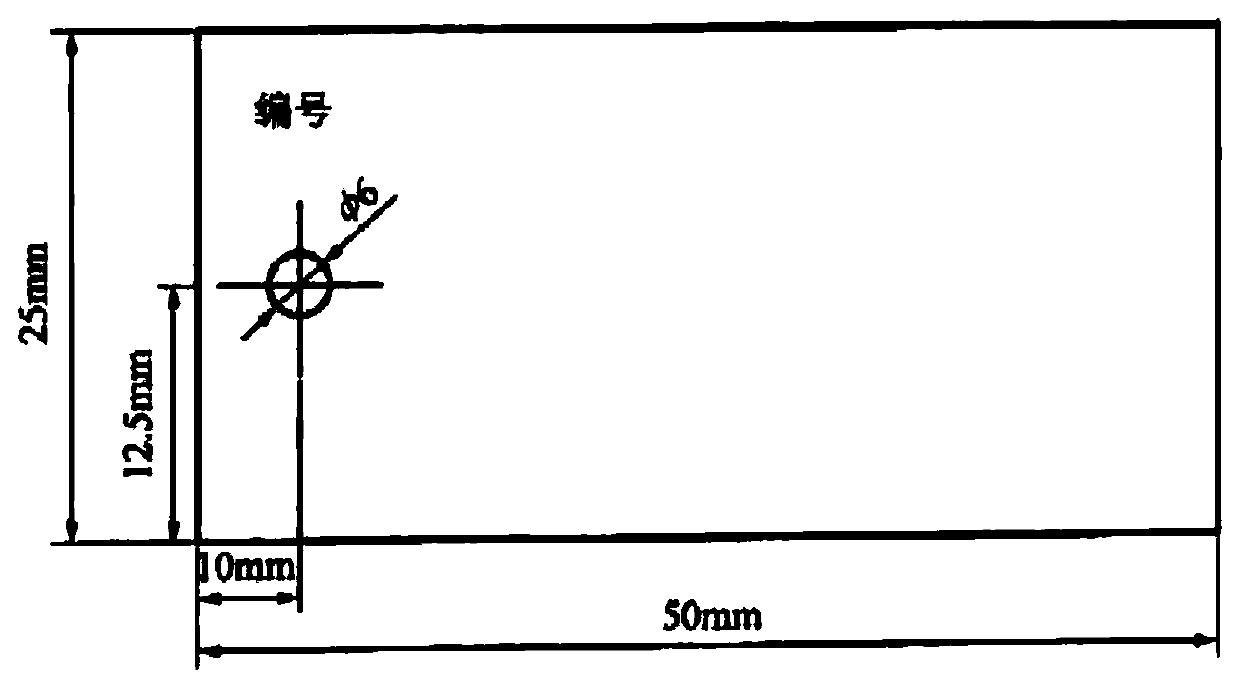

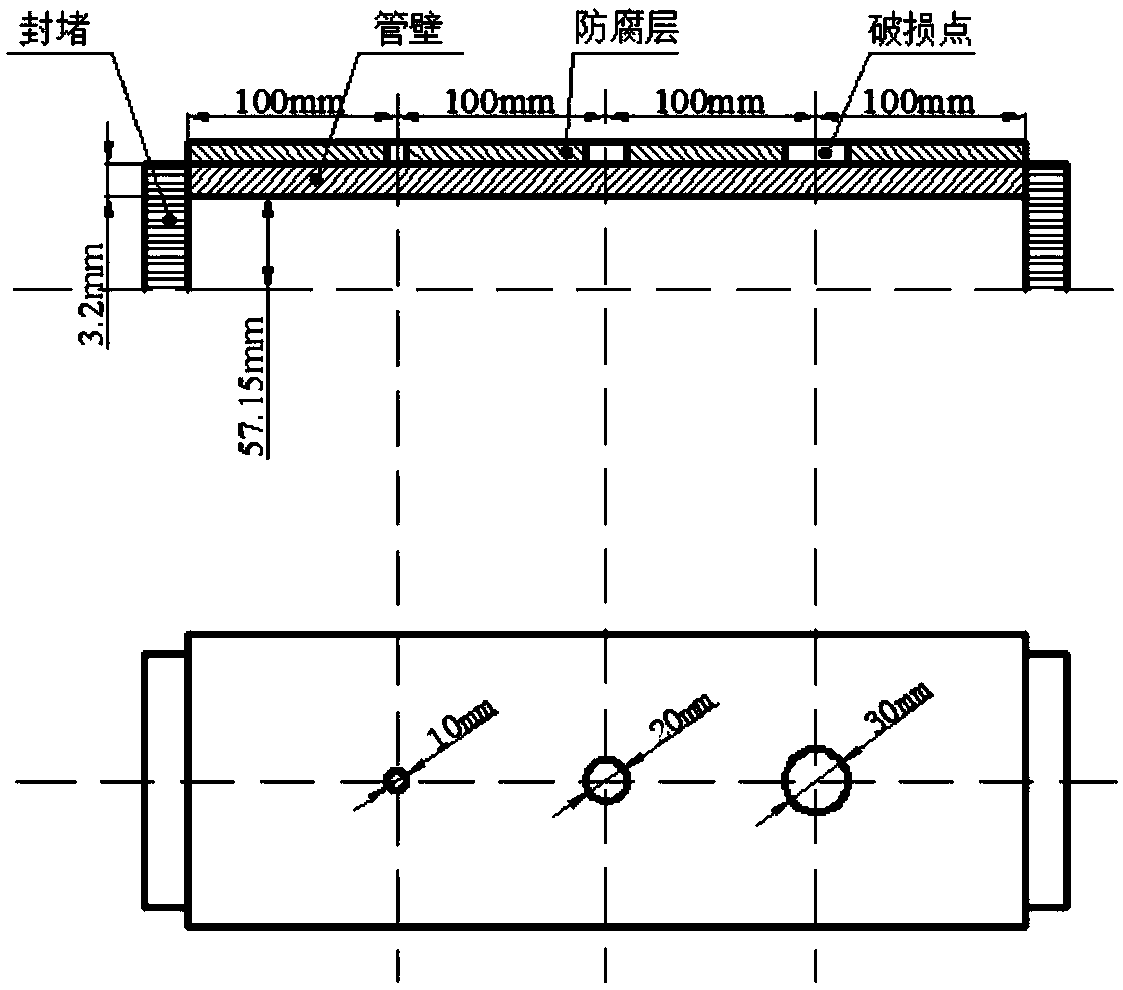

[0063] S2. Collect relevant factors through buried test materials and field tests;

[0064] S3. Analyze the corrosion characteristics of the buried test piece and pipe section obtained in the S2 test, and calculate the corrosion rate;

[0065] S4, through the result obtained in S3, carry out the key factor analysis of soil corrosion;

[0066] S5, in conjunction with the data obtained in S4, establish a soil physical and chemical properties and corrosion rate relationship model;

[0067] S6. Evaluate the safety of the pipeline according to the model established in S5, and predict the remaining life of the pipeline.

[0068] Preferably, the soil corrosion factors in the S1 include: on-site testing of soil resistivity, redox potential and pipeline natural corrosion p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com