Indoor dust suppression device for construction site

A construction site and dust reduction device technology, applied in the direction of using liquid separation agent, suction nozzle, and dispersed particle separation, etc., can solve the problems of dust treatment that cannot be grounded, and achieve the effects of improving dust reduction efficiency, expanding the area, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

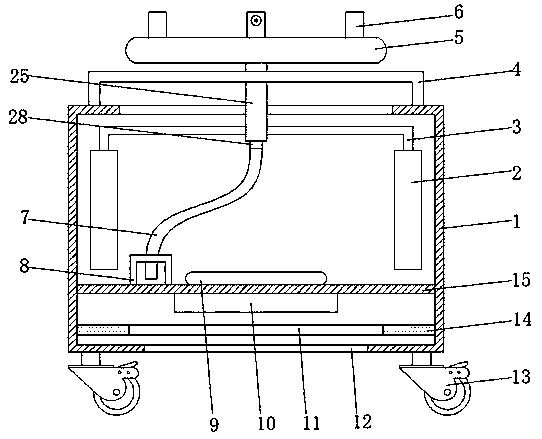

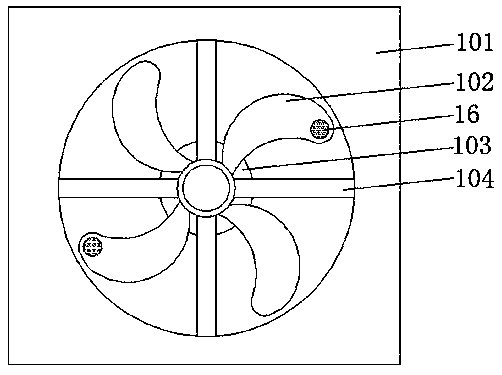

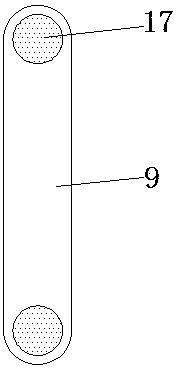

[0029] refer to Figure 1-6 , an indoor dust suppression device for a construction site, comprising a casing 1, the bottom end between the inner walls on both sides of the casing 1 is fixedly connected with a partition 15 by bolts, and the partition 15 separates the casing 1 into water storage at the top of the partition 15 chamber and the dust suction chamber at the bottom of the partition 15, the bottom of the partition 15 is fixedly connected with a negative pressure fan 10 by bolts, and the shell 1 is fixedly connected with a frame 14 by bolts between the inner walls of both sides of the dust suction chamber, and the frame 14 It is located below the negative pressure fan 10, and the middle part of the frame 14 is provided with an opening. The frame 14 is fixedly connected with an isolation pad 11 by bolts at the opening. The material of the isolation pad 11 is a porous material. There is a dust suction port 12 at the bottom, so the negative pressure can be generated by the...

Embodiment 2

[0036] refer to Figure 7 , an indoor dust suppression device for a construction site. Compared with Embodiment 1, in this embodiment, in order to make the replacement and cleaning of the isolation pad 11 more convenient, the frame 14 includes a first frame 1401 and a second frame 1402, the first frame 141 and the second frame 1402. The hinges 26 are fixedly connected by bolts between the second frames 142, and the four corners of the top of the second frame 142 are fixedly connected with fixing piles 27 by bolts, and the four corners of the spacer 11 are all provided with fixing holes, and the fixing piles 27 is adapted to the fixing hole, so the spacer 11 can be easily removed by separating the first frame 141 and the second frame 142 after use, thereby bringing convenience to the replacement and cleaning of the spacer 11.

[0037] When in use: first inject clear water into the water storage chamber, then take out the frame 14 and separate the first frame 141 and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com