Method and device for fault diagnosis and treatment of hydrogen fuel cell

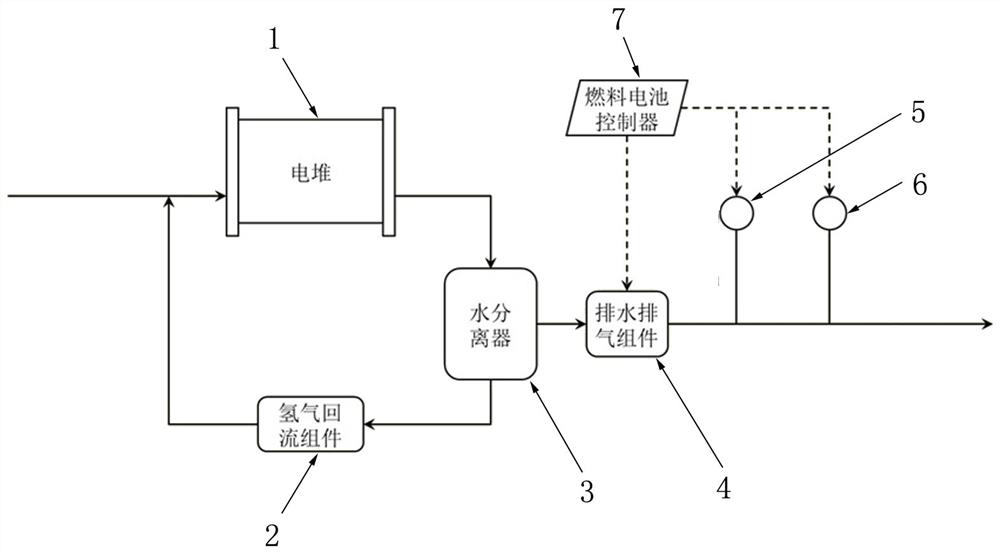

A fuel cell and fault diagnosis technology, applied to fuel cells, circuits, electrical components, etc., can solve problems affecting fuel cell performance, stack performance degradation, and cathode gas entry, etc., to avoid excessive impurity gas content and fault diagnosis. Timely and accurate, simple installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

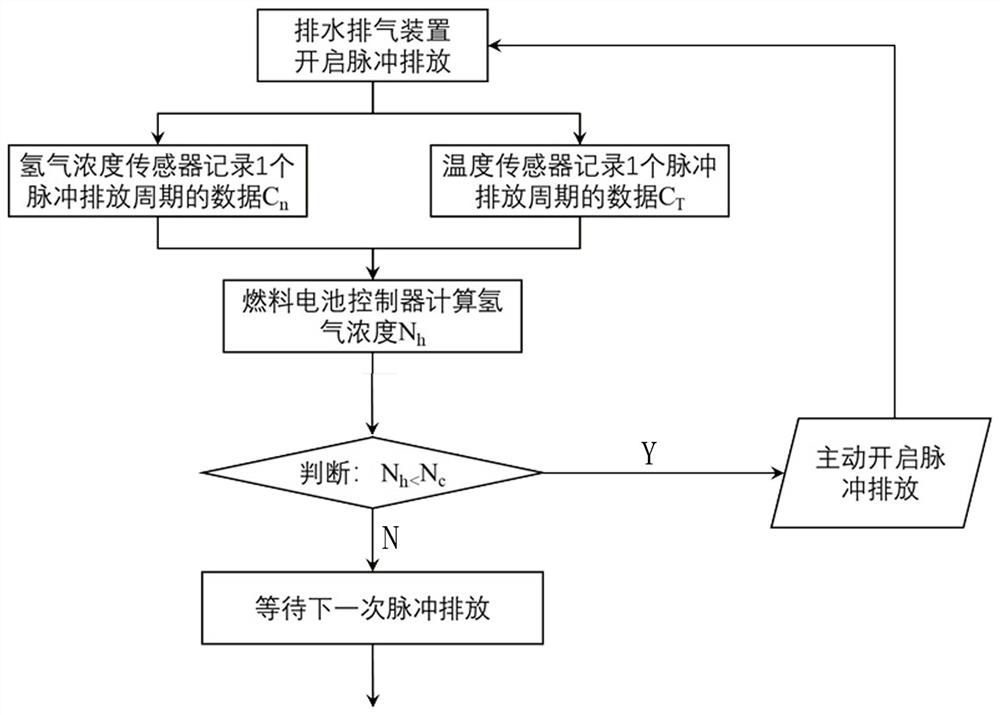

[0039] like figure 2 As shown in the figure, a fault diagnosis and processing method for a hydrogen fuel cell is characterized in that, when the drainage and exhaust device starts pulse discharge, a hydrogen concentration sensor is used to record a signal curve of a pulse discharge period, which is marked as C n , using the temperature sensor to record the signal curve of one pulse discharge cycle, marked as C T ; fuel cell controller according to C n and C T Calculate the hydrogen concentration value N inside the hydrogen supply system h .

[0040] The specific fault diagnosis and processing method is as follows: the hydrogen concentration threshold N is stored in the fuel cell controller. c , by comparing the hydrogen concentration value N h and the hydrogen concentration threshold N c to judge whether the hydrogen fuel cell fails; if N h c , indicating that the concentration of impurity gas in the hydrogen supply system is too high; at this time, the fuel cell contr...

Embodiment 2

[0045] A fault diagnosis and processing method for a hydrogen fuel cell, which is basically the same as that of Embodiment 1, except that the hydrogen concentration algorithm is different.

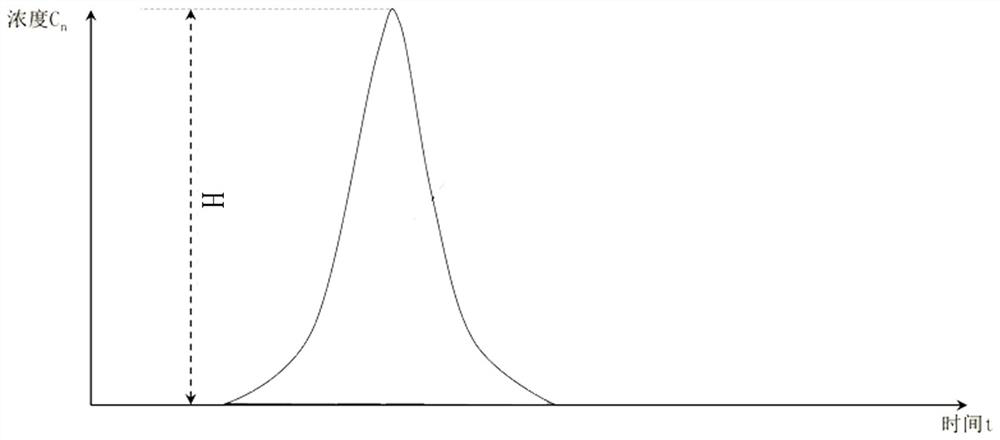

[0046] like image 3 As shown, in this embodiment, the hydrogen concentration algorithm uses the hydrogen concentration sensor signal C in the database Map n The hydrogen concentration peak height H is used as a key indicator, and the experimental data is used to fit N at a certain temperature to obtain N s and the functional relationship between H.

[0047] N s = f1(H).

[0048] Then according to N s The corresponding relationship with H obtains the hydrogen concentration value N at a certain temperature and a certain hydrogen concentration peak height H h .

[0049] As for the specific data fitting method, it is the common technical knowledge mastered by those skilled in the art, and will not be described in detail here.

Embodiment 3

[0051] A fault diagnosis and processing method for a hydrogen fuel cell, which is basically the same as that of Embodiment 1, except that the hydrogen concentration algorithm is different.

[0052] like Figure 4 As shown, in this embodiment, the hydrogen concentration algorithm uses the hydrogen concentration sensor signal C n The hydrogen concentration peak integral area Area is used as a key indicator, and the test data is used to obtain N at a certain temperature. s and the functional relationship between Area.

[0053] N s = f2(Area).

[0054] Then according to N s The corresponding relationship with Area obtains the hydrogen concentration value N under a certain temperature and a certain hydrogen concentration peak integral area Area h .

[0055] As for the specific data fitting method, it is the common technical knowledge mastered by those skilled in the art, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com