Material mixing standing equipment

A wake-up and equipment technology, applied in the direction of mixers, dissolution, chemical instruments and methods, etc., can solve problems such as difficult cleaning, limited area, and increased fork speed, so as to achieve a rapid and stable state of the mixture and reduce the generation of lumps , Reduce the effect of frictional heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

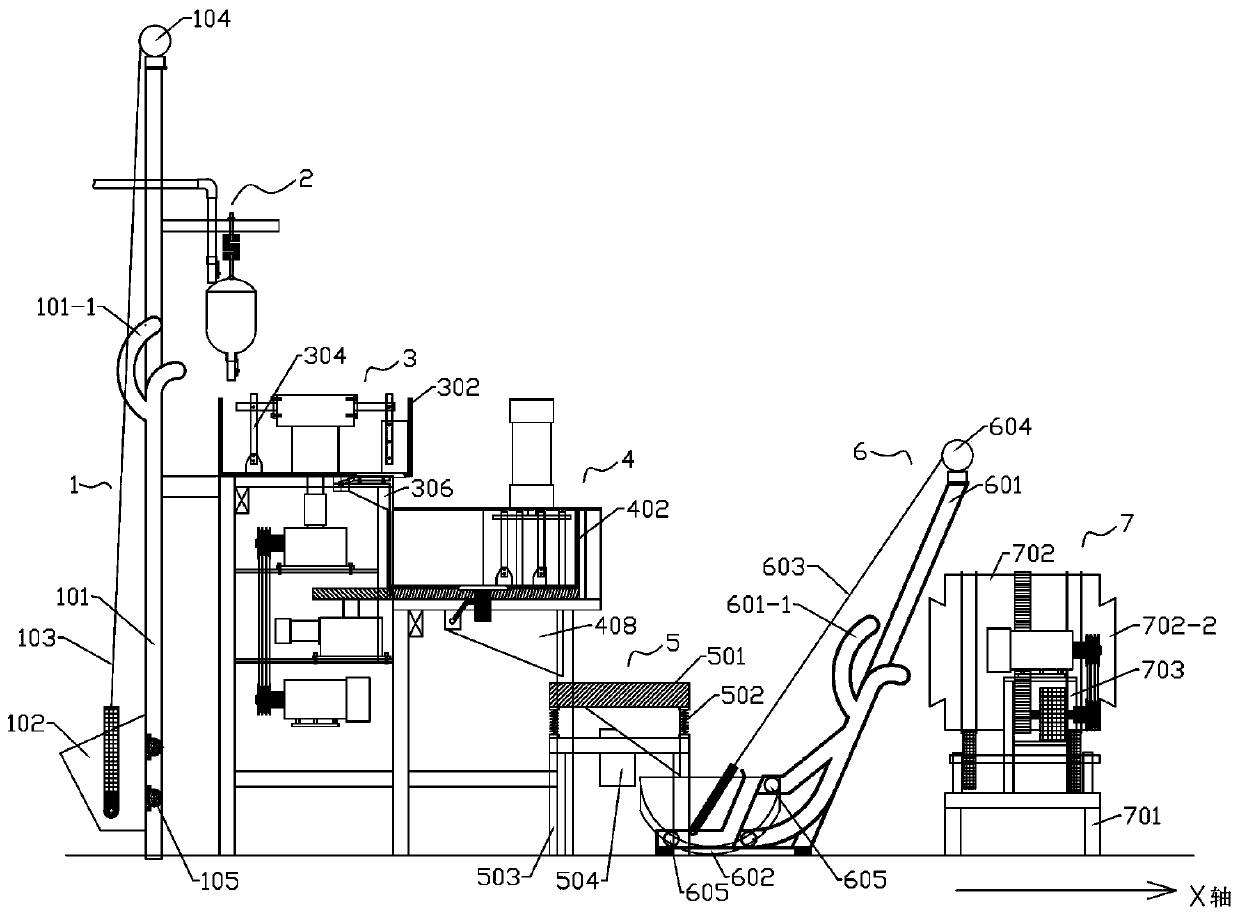

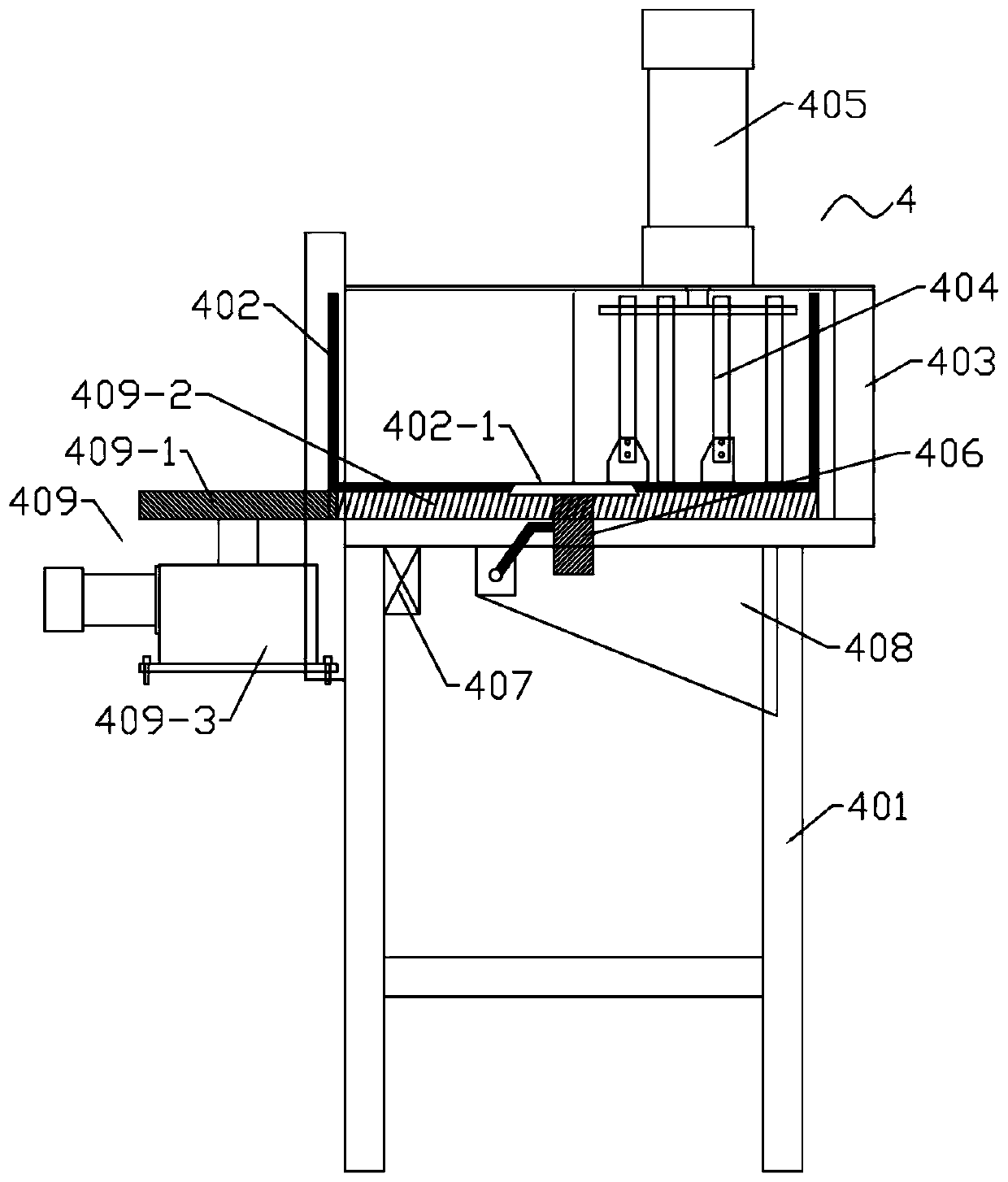

[0019] Specific Example 1: See Figure 1 to Figure 4 , in the embodiment of the present invention, a kind of material mixing equipment comprises the first material lifting mechanism 1, the first material mixing pot 3, the second material mixing pot 4, the second material lifting mechanism 6 and the waking material pot 7, the The first material lifting mechanism 1 is arranged on one side of the first mixing pot 3, and the second mixing pot 4 is on the other side of the first mixing pot 3 and below the first mixing pot 3, and the second mixing pot 4 is below the first mixing pot 3. The third mixing pot is on the other side of the second mixing pot 4, and the second lifting mechanism 6 is between the second mixing pot 4 and the third mixing pot and is used for the transfer of the mixed material. A liquid feeding device 2 is provided above the first mixing pot 3 for transporting resin liquid into the first mixing pot 3 .

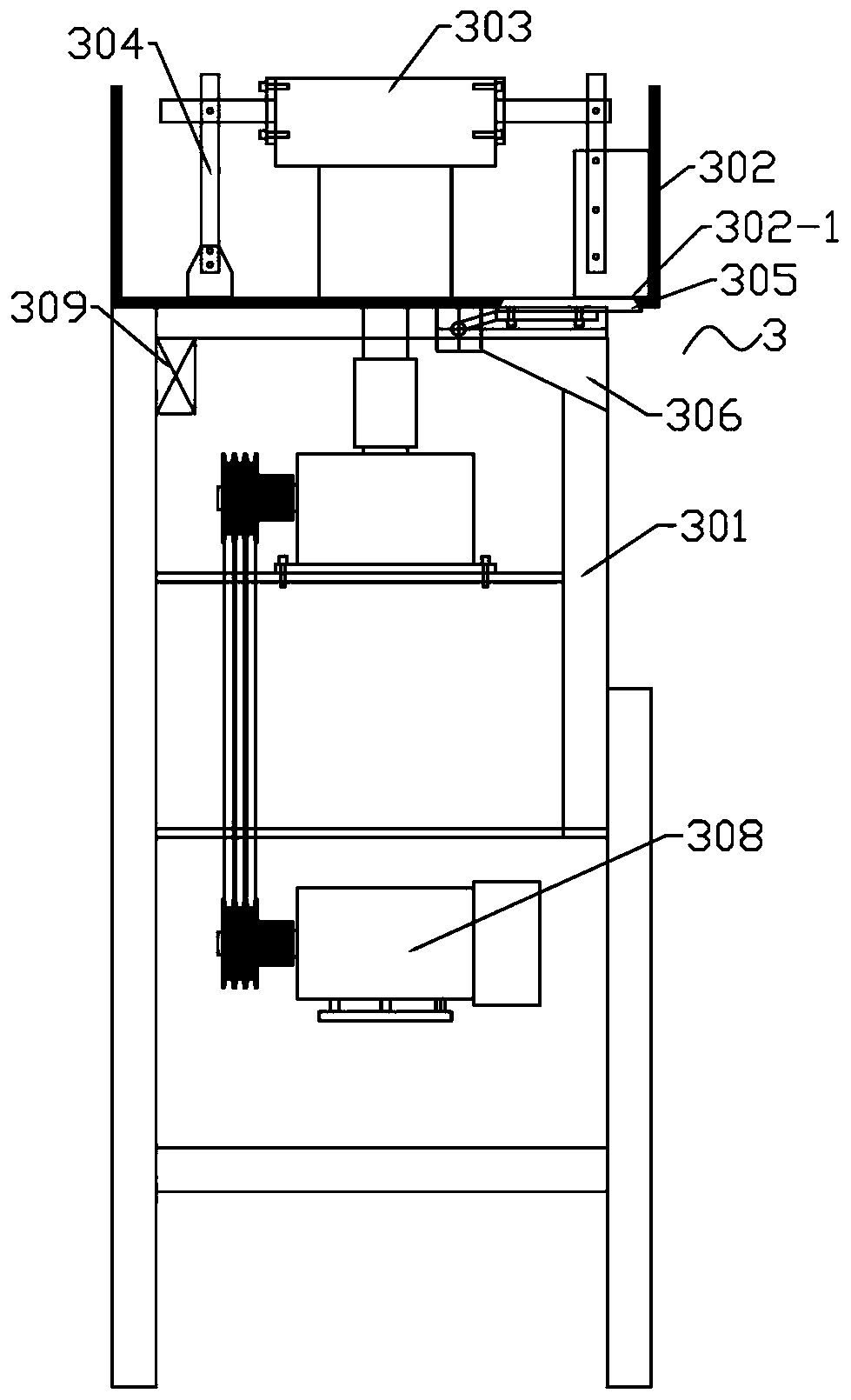

[0020] The first mixing pot 3 includes a first support fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com