Dry powder of iron tailings micropowder mortar for construction mortar and preparation method thereof

A technology of mortar dry powder and iron tailings, which is applied in the field of building materials, can solve the problems of low fly ash and slag content, high mortar folding ratio, poor crack resistance, etc., and achieve energy saving, simple production process, and equipment The effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

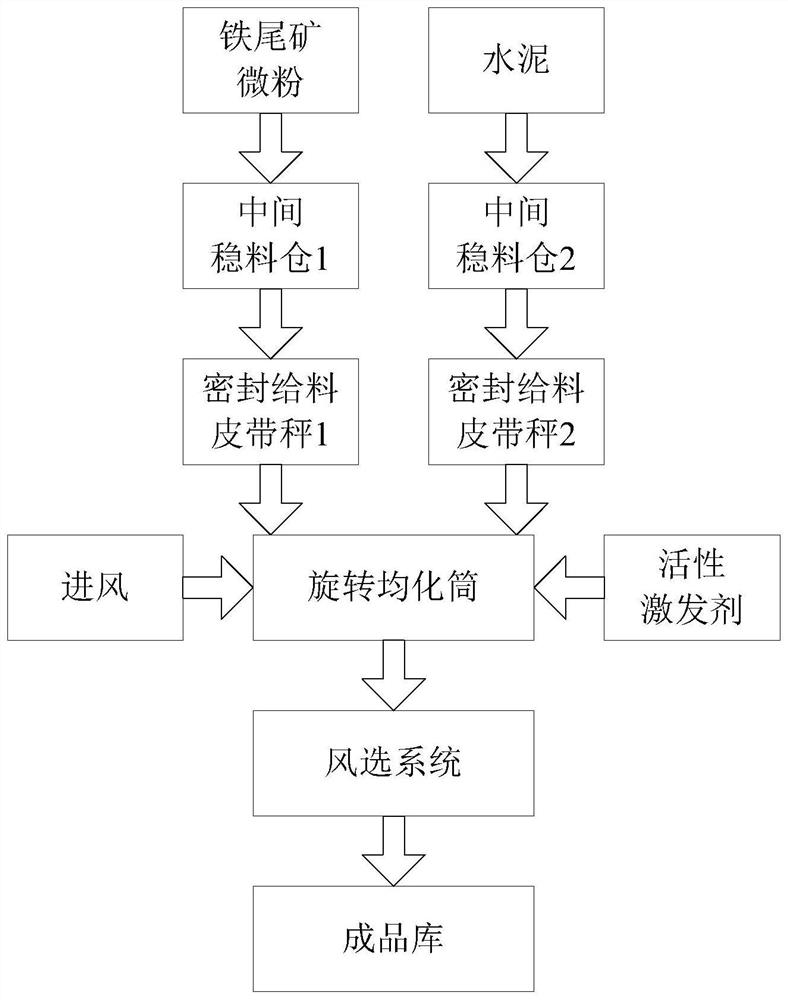

[0017] In order to further describe the present invention in detail, the following description is made with reference to the accompanying drawings and specific embodiments. In particular, the following examples are merely illustrative of the present invention and the present invention is not limited to the following examples.

[0018] The present invention is a dry powder of iron tailings micropowder mortar for building mortar, which is characterized in that it comprises powders obtained by mixing the raw materials according to the following weight percentages and then homogenizing twice: iron tailings micropowder: 70%-85%; P. O42.5R cement: 15%-30%; active stimulator: 0.1%-0.15%; the fineness of the iron tailings fine powder is 45μm square hole sieve, the sieve residue is not more than 5%, and the specific surface area is more than 500m 2 / kg; the cement is at least one of the ordinary Portland cement, aluminate cement, and sulfoaluminate cement with the label of 42.5R; Surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com