Preparation process of windage yaw prevention jumper insulator for 500kV transmission line

A preparation process and technology for transmission lines, applied in circuits, insulators, suspension/strain insulators, etc., can solve the problems of insulators that cannot be adapted to wind-proof bias jumpers, and achieve the purpose of preventing wind bias flashover, ensuring stability, and improving strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

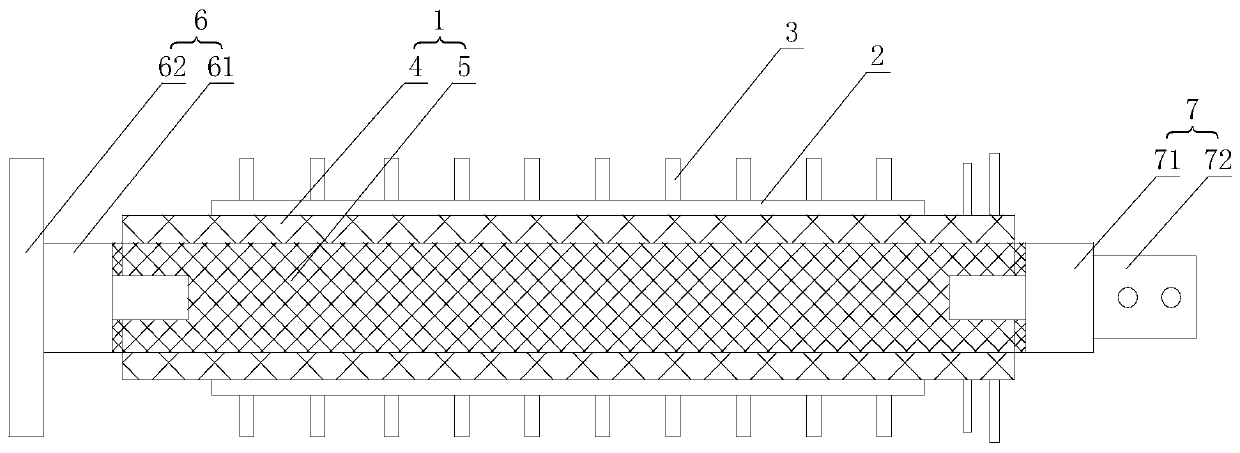

[0030] Such as figure 1 As shown, a preparation process of a wind deflection jumper insulator for a 500kV transmission line, the wind deflection jumper insulator includes a core 1 and a sheath 2 coated on the outside of the core 1, and the sheath 2 is provided with Umbrella skirt 3, the core body 1 includes a hollow tube 4 and a polyurethane insulator 5 filled in the hollow tube 4, the core body 1 includes a high-voltage end 7 and a low-voltage end 6, and the low-voltage end 6 includes a first mandrel 61 And the flange 62, the first mandrel 61 is arranged in the hollow pipe 4, the flange 62 is arranged on the first mandrel 61, and the high pressure end 7 includes the second mandrel 71 and the connecting plate 72 , the second mandrel 71 is arranged in the hollow tube 4, the connecting plate 72 is arranged on the second mandrel 71, and the polyurethane insulator 5 is prepared by polyurethane resin; the preparation process includes the following steps in sequence:

[0031] Step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com