Method for welding components on circuit board

A circuit board and component technology, applied in the field of circuit board welding components, can solve the problems of cumbersome manual welding operation, low production efficiency, circuit board damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings.

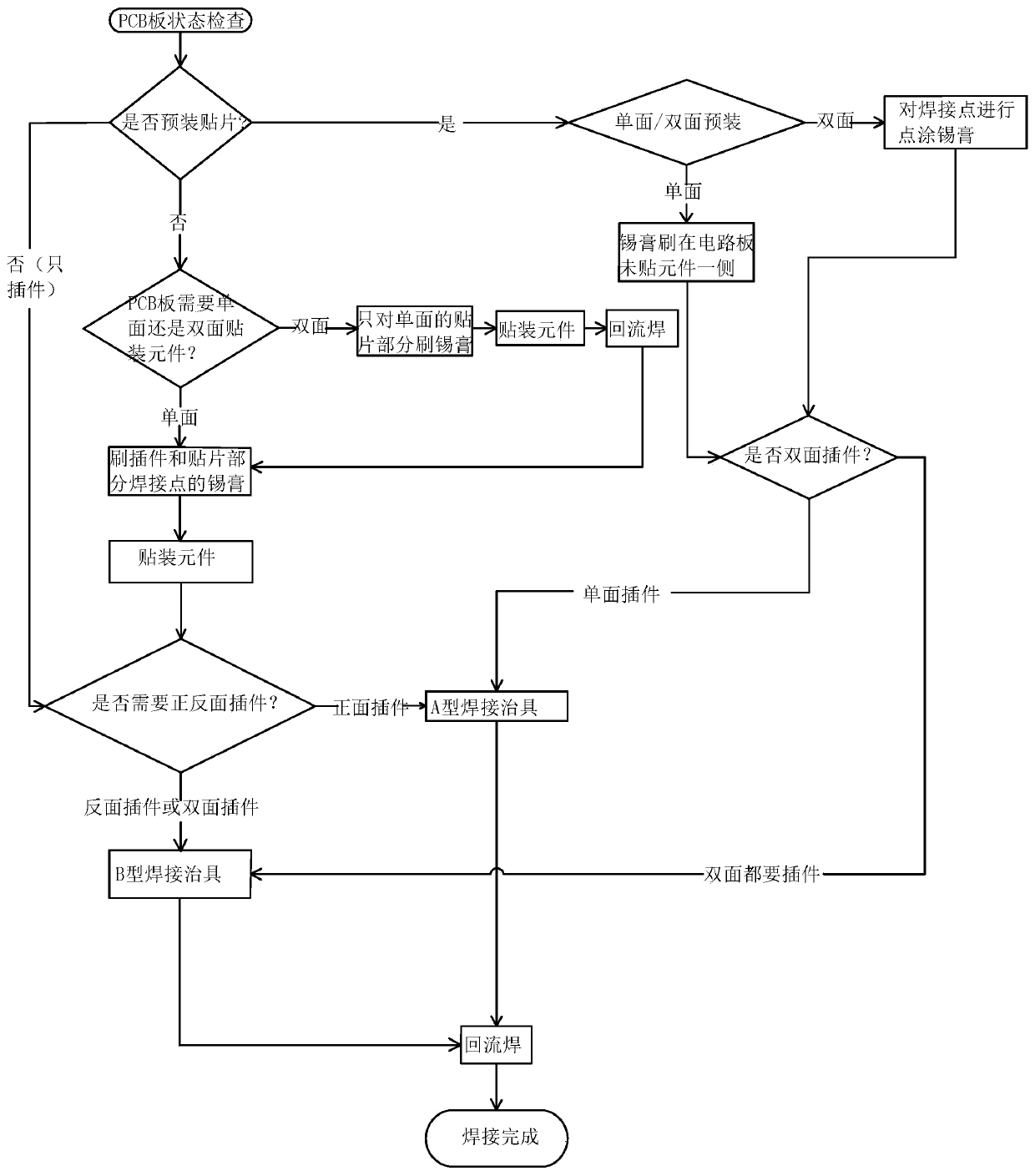

[0047] like figure 1 As shown, a method for soldering components on a circuit board mainly includes the following steps:

[0048] S1 PCB copper-clad circuit boards are divided into two types according to the factory specifications: pre-installed boards with pre-installed patches and empty boards without any components. The processes used for pre-installed boards and empty boards are different. , so the circuit board needs to be classified first after entering the factory. The classification is based on whether the circuit board has been pre-installed with patches. If there is pre-installation, it is pre-installed on one side or double-sided. Whether double-sided chips are needed, and whether double-sided plug-ins are needed, after specific subdivision, the mainstream circuit boards that are widely used at present mainly include the following types:

[0049]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com