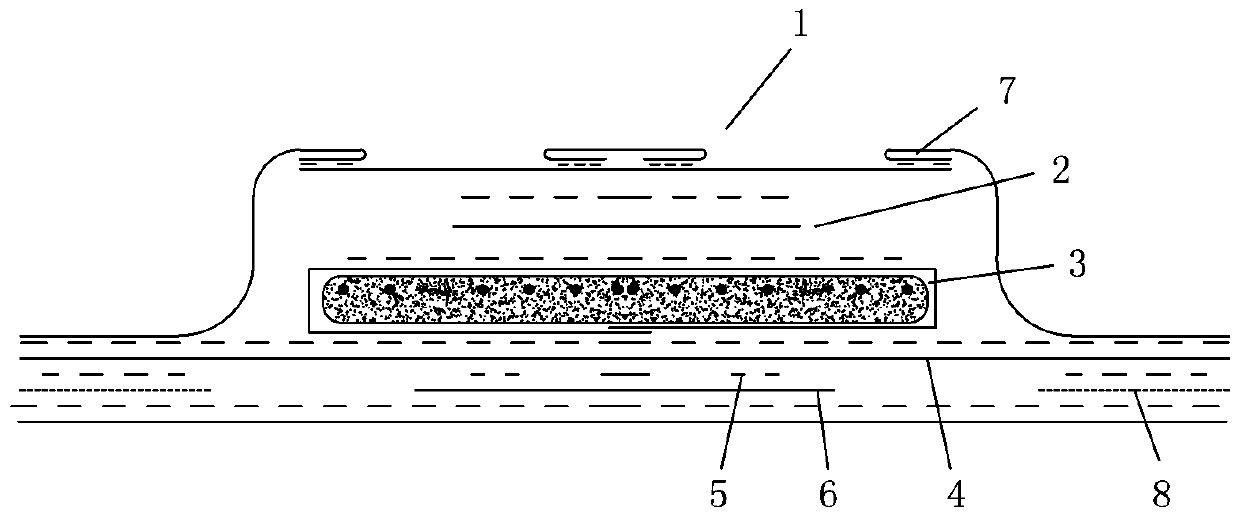

Double-layer fabric sanitary napkin

A technology of double-layer fabrics and sanitary napkins, applied in the field of sanitary napkins, can solve the problems of reducing carbon emissions, worsening comfort, increasing costs, etc., and achieving the effects of green economy, environmental protection, carbon emissions, improved fit performance, and improved comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

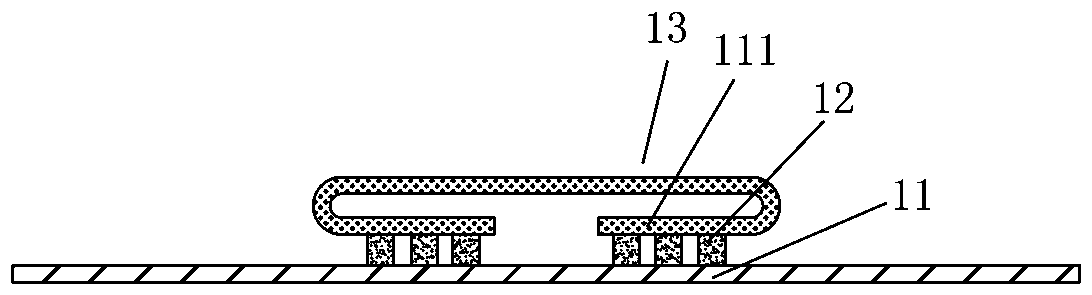

specific Embodiment 1

[0021] refer to figure 2 , the double-layer fabric layer 1 is sequentially composed of a surface layer 11, a joint portion 12 and a central surface layer 13 from bottom to top, the central surface layer 13 is located at the center line of the surface layer 11, and the central surface layer 13 The width is smaller than the width of the surface layer 11, the two sides of the central surface layer 13 are folded inwardly to form folded edges 111 that do not overlap each other, the bottom of the folded edges 111 is connected with the joint portion 12, and the central The thickness of the surface layer 13 after folding is greater than the thickness of the surface layer 11, and the thickness difference between the central surface layer 13 and the surface layer 11 after folding is not less than 0.7mm. The central surface layer 13 is made of hot-air non-woven fabric, pure Any one of cotton spunlaced cloth or polylactic acid non-woven fabric, the width range of the surface layer 11 is ...

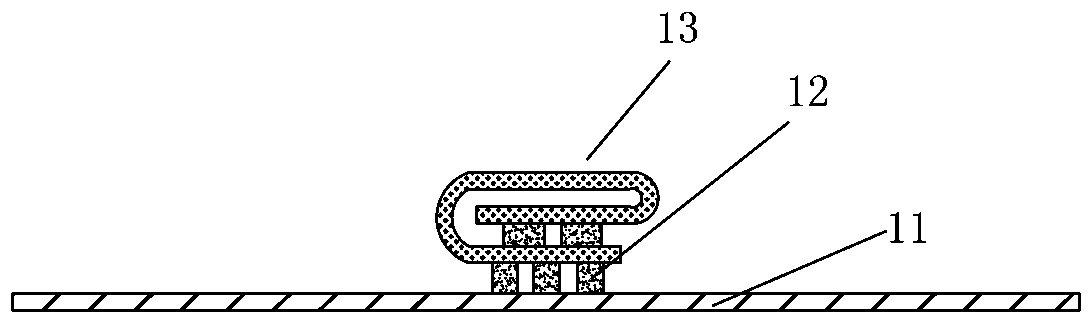

specific Embodiment 2

[0023] refer to image 3 , the double-layer fabric layer 1 is sequentially composed of a surface layer 11, a joint portion 12 and a central surface layer 13 from bottom to top, the central surface layer 13 is located at the center line of the surface layer 11, and the central surface layer 13 The width is smaller than the width of the surface layer 11, and the central surface layer 13 is folded horizontally continuously to form a folded structure of at least two layers. The thickness of the folded central surface layer 13 is greater than the thickness of the surface layer 11. The central surface layer The thickness difference between 13 and the surface layer 11 after folding is not less than 0.7mm. The central surface layer 13 is made of any one of hot-air non-woven fabric, pure cotton spunlace fabric or polylactic acid non-woven fabric. The width of the surface layer 11 The range is 55-95mm. The joint part 12 is formed by hot melt adhesive or the surface layer 11 and the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com