Crushing and drying device for chemical fertilizer production

A drying device and fertilizer technology, applied in drying, drying machine, manure drying, etc., can solve the problems of no drying function, poor crushing effect, and easy clogging of the screen, so as to reduce the blind area of mixing and have good sealing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

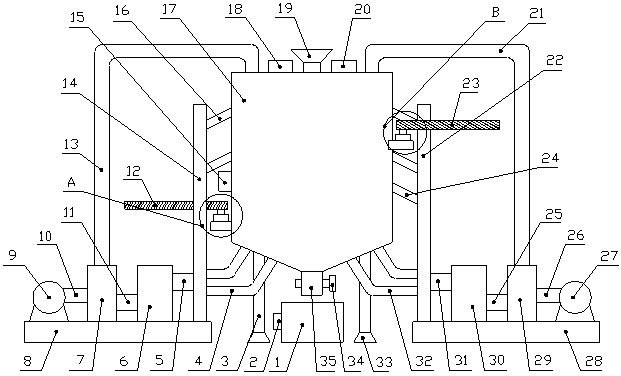

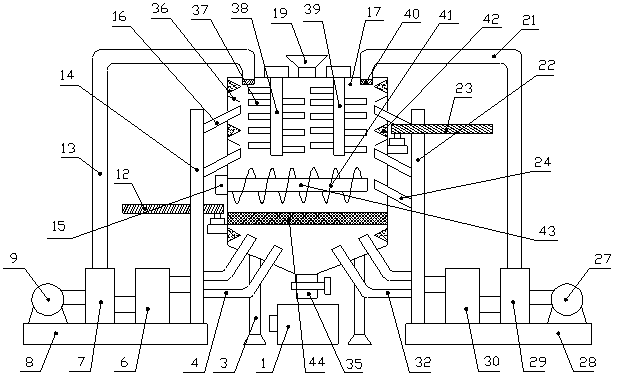

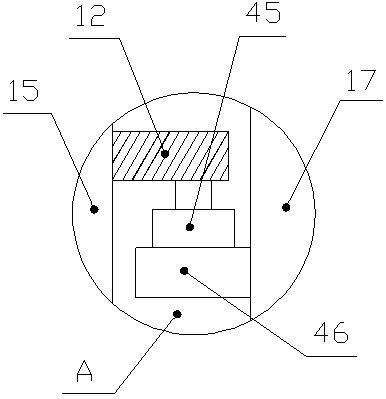

[0020] Such as Figure 1-4As shown, a crushing and drying device for fertilizer production includes a base A8, a crushing tank 17 and a base B28, and the upper end of the base A8 is sequentially connected with a blower A9, a dehumidifier A7, a heater A6 and a feeder from left to right. The air duct A14, the upper end of the base B28 is sequentially connected with the blower B27, the dehumidifier B29, the heater B30 and the air inlet pipe B22 from right to left, and the air outlet of the blower A9 is connected with the dehumidifier A7 through the pipeline A10, The dehumidifier A7 is connected to the heater A6 through the pipeline B11, the heater A6 is connected to the left end of the air inlet pipe A14 through the pipeline C5, and the air outlet of the blower B27 is connected to the dehumidifier B29 through the pipeline D26. The dehumidifier B29 is connected to the heater B30 through the pipe E25, the heater B30 is connected to the right end of the air inlet pipe B22 through th...

Embodiment 2

[0023] Such as Figure 1-4 As shown, a crushing and drying device for fertilizer production includes a base A8, a crushing tank 17 and a base B28, and the upper end of the base A8 is sequentially connected with a blower A9, a dehumidifier A7, a heater A6 and a feeder from left to right. The air duct A14, the upper end of the base B28 is sequentially connected with the blower B27, the dehumidifier B29, the heater B30 and the air inlet pipe B22 from right to left, and the air outlet of the blower A9 is connected with the dehumidifier A7 through the pipeline A10, The dehumidifier A7 is connected to the heater A6 through the pipeline B11, the heater A6 is connected to the left end of the air inlet pipe A14 through the pipeline C5, and the air outlet of the blower B27 is connected to the dehumidifier B29 through the pipeline D26. The dehumidifier B29 is connected to the heater B30 through the pipe E25, the heater B30 is connected to the right end of the air inlet pipe B22 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com