A small labor-saving sand sieving machine for interior decoration

A technology for interior decoration and sand screening machine, applied in the direction of screen, solid separation, grille, etc., can solve the problems of inconvenience, laborious use, high labor intensity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples or drawings are used to illustrate the present invention, but not to limit the scope of the present invention.

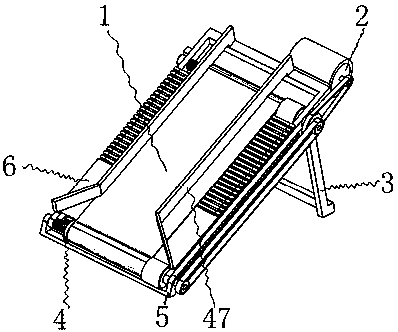

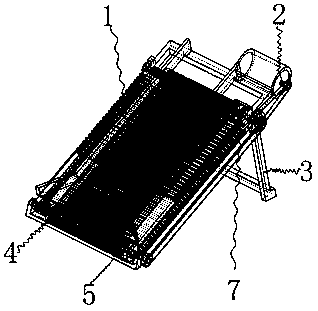

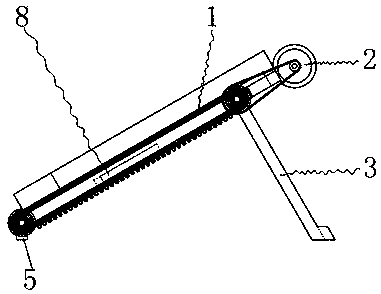

[0060] Such as figure 1 , 2 As shown, it includes a conveyor belt 1, a driving motor 2, a rear support 3, a rolling wheel 4, a front support 5, a limiting plate 6, a vibration mechanism 7, a triangular push block 8, a support roller 9, a fixed frame 10, and a support shaft 11. Among them such as Figure 5 , 8 As shown, the upper and lower ends of the fixed frame 10 are respectively equipped with a supporting shaft 11, as Figure 8 As shown, the front bracket 5 is fixedly installed on the lower end of the fixed frame 10, and the rear bracket 3 is mounted on the upper support shaft 11 of the two support shafts 11 through rotation fit; Figure 9 As shown, two clamping blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com