Injection mold for refrigerator drawer

An injection mold and mold technology, applied in the field of injection molds for refrigerator drawers, can solve the problems of easy generation of air bubbles, uneven composition, and lack of cooling function, etc., and achieve the effects of facilitating cooling molding, increasing heat conduction rate, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

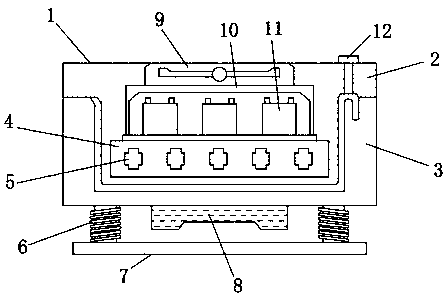

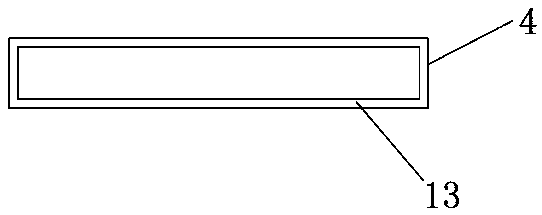

[0021] Such as Figure 1-2 Shown, a kind of injection mold for refrigerator drawer comprises mold main body 1, upper mold 2 and lower mold 3, and described mold main body 1 is made up of upper mold 2 and lower mold 3, and described upper mold 2 is positioned at lower mold 3 top, The inside of the mold main body 1 is provided with a heat dissipation pipe 4, the upper part of the heat dissipation pipe 4 is fixedly connected to the cavity 10, and the inside of the cavity 10 is provided with a semiconductor refrigerator 11, and the upper part of the cavity 10 is inlaid with a heat dissipation fan 9. An injection port 12 is installed at one end of the upper part of the mold body 1 , a graphene heat conduction layer 13 is inlaid on the inner wall of the heat dissipation pipe 4 , and ice crystals 5 are filled inside the heat dissipation pipe 4 .

[0022] In this embodiment, by setting ice crystal 5, graphene heat-conducting layer 13, semiconductor refrigerator 11 and heat dissipation...

Embodiment 2

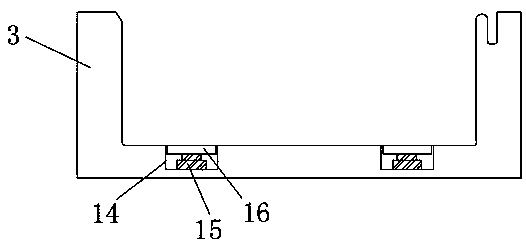

[0024] Such as figure 1 with image 3 As shown, vibrating springs 6 are installed at both ends of the bottom of the lower mold 3, the bottom of the vibrating spring 6 is fixedly connected to the connecting base 7, the lower mold 3 is connected to the connecting base 7 through the vibrating spring 6, and the lower mold 3 The bottom is provided with a vibrating motor 8, and both ends of the lower mold 3 are inlaid with sliding grooves 14, the inner wall of the sliding groove 14 is slidingly connected to the sliding block 16, and the sliding block 16 and the upper surface of the lower mold 3 are located on the same horizontal plane. A hydraulic rod 15 is mounted on the inner bottom side of the sliding groove 14 , and the upper part of the hydraulic rod 15 is engaged with the sliding block 16 .

[0025] In this embodiment, by setting the vibrating motor 8 and the vibrating spring 6, the uniformity of the molding of the mold body 1 is effectively improved, and bubble grooves are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com