Paper covering equipment for continuous plates

A plate and paper-covering technology, which is applied in the field of battery plate production and processing, can solve the problems of high labor intensity, excessive loss of lead paste, environmental pollution, etc., and achieve the effects of easy paper covering, deformation prevention, and neat covering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

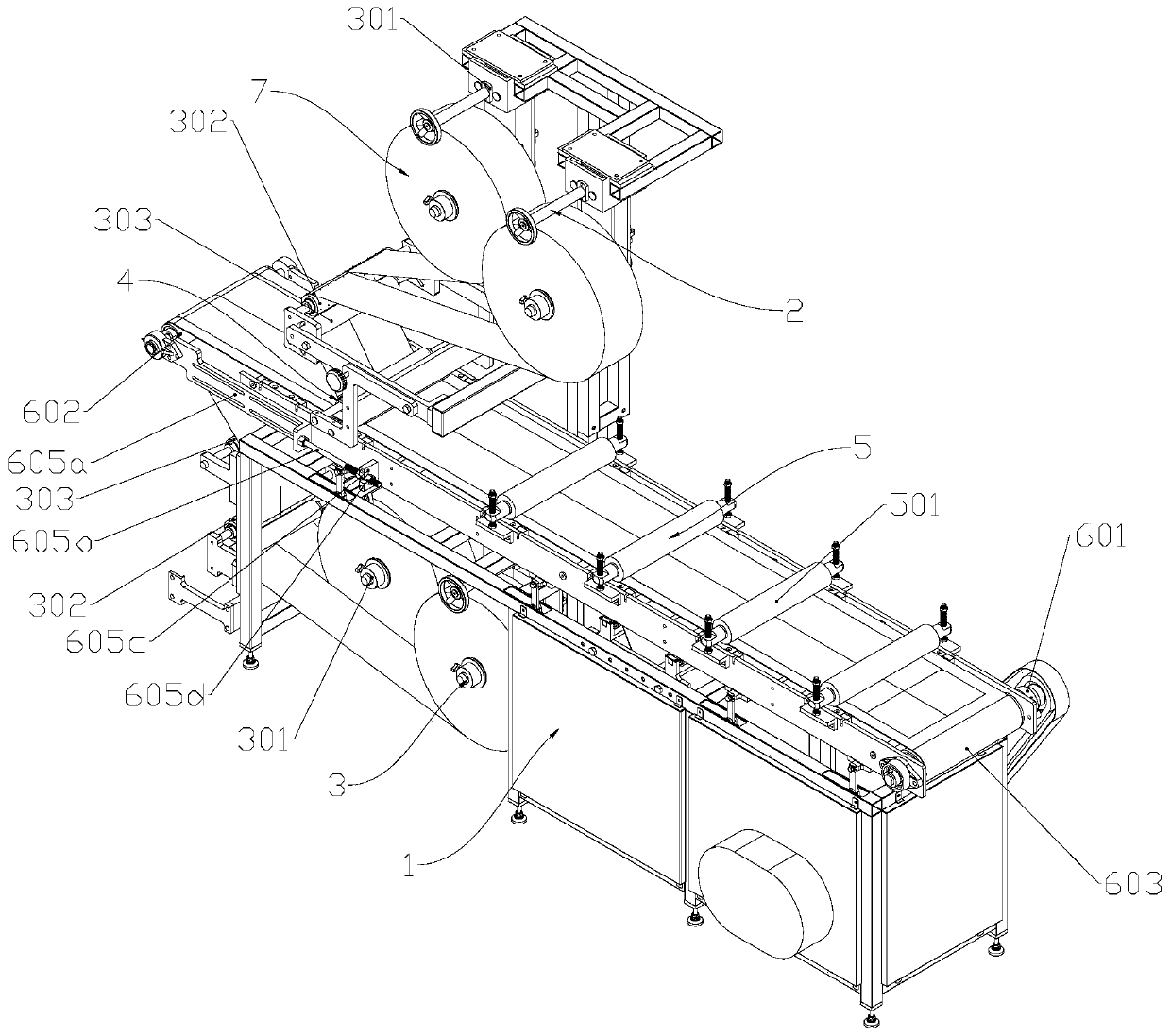

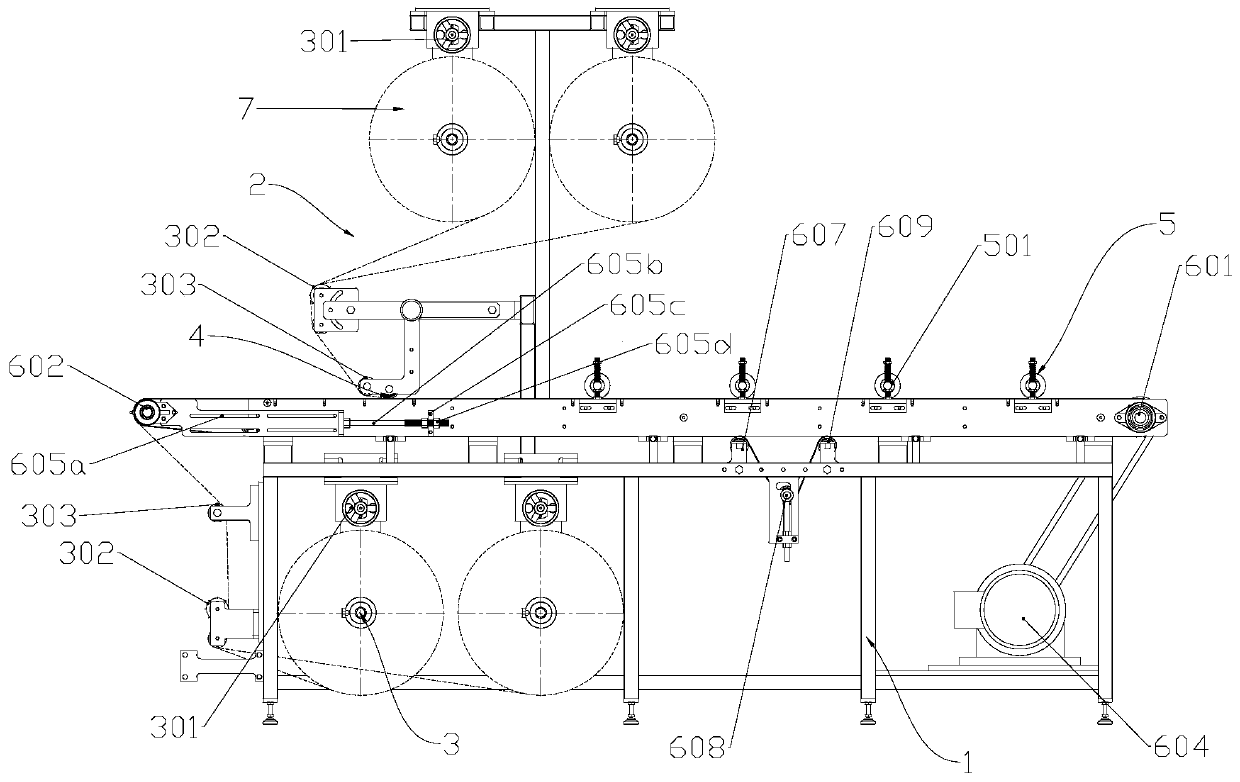

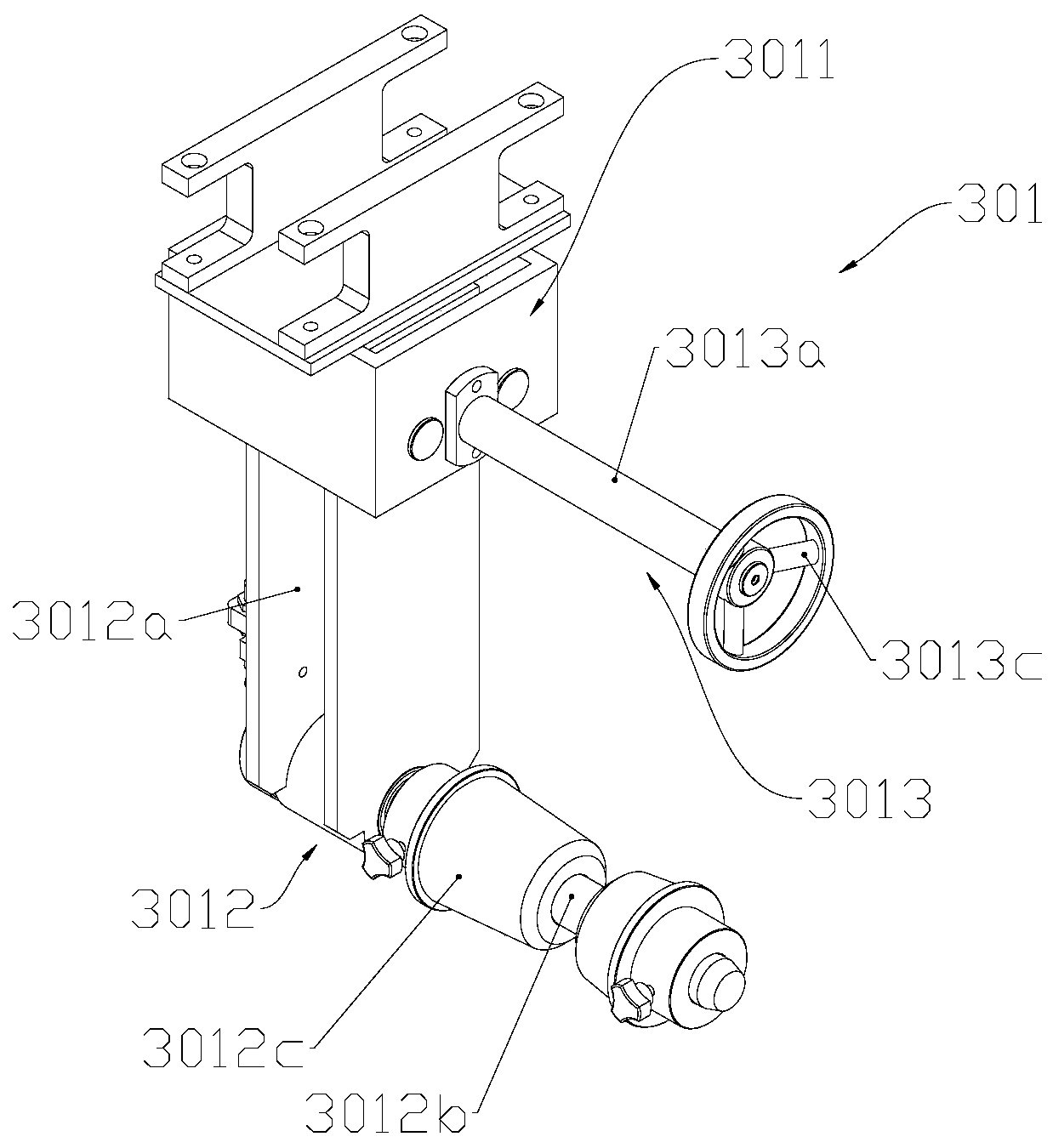

[0026] Such as Figure 1-Figure 9 As shown, the paper covering equipment for continuous pole plates in this embodiment includes a frame 1, a conveying assembly arranged on the frame 1, an upper plate paper supply device fixed on the frame 1 and located above the conveying assembly Paper assembly 2, the lower plate paper supply assembly 3 fixed on the frame 1 and located below the conveying assembly, and the plate for bonding the pole plate to the upper and lower sides of the plate paper, which is arranged above the front section of the conveying path of the conveying assembly The pre-pressing roller 4 and the secondary pressing assembly 5 arranged above the rear section of the conveying path of the conveying assembly make the pole plate closely adhere to the pole plate paper on the upper and lower sides. When the present invention is used, it is set at the discharge port of the plate coating machine, and the pole plate is filled with lead paste by the plate coater and then ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com