Dry towing transporting float-on process of floating production, storage and offloading device

A floating production and floating installation technology, which is applied in the direction of transportation and packaging, tugboats, floating buildings, etc., can solve the problems of narrow relative positions, protruding hulls and floating installation guide devices, etc., to prevent damage and improve engineering quality. Efficiency and safety, and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

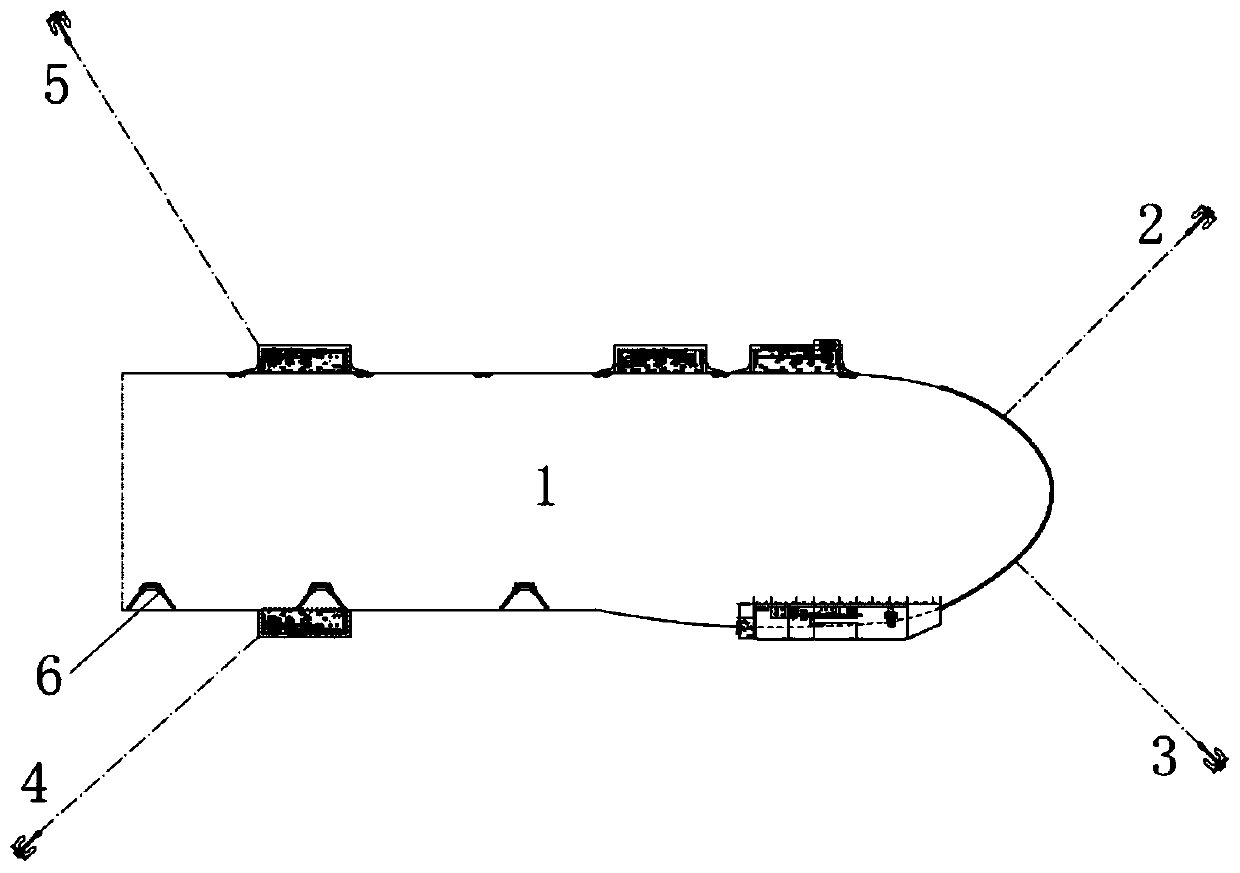

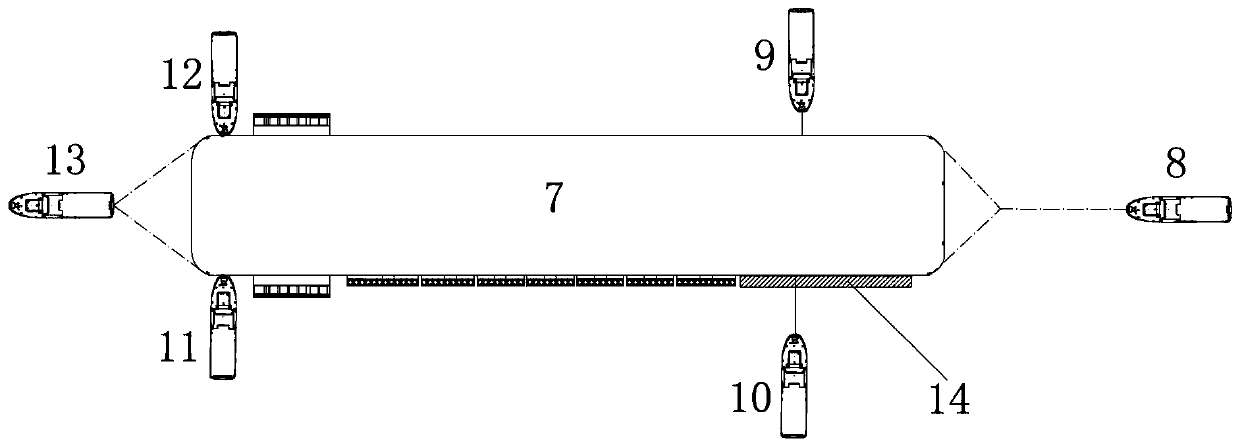

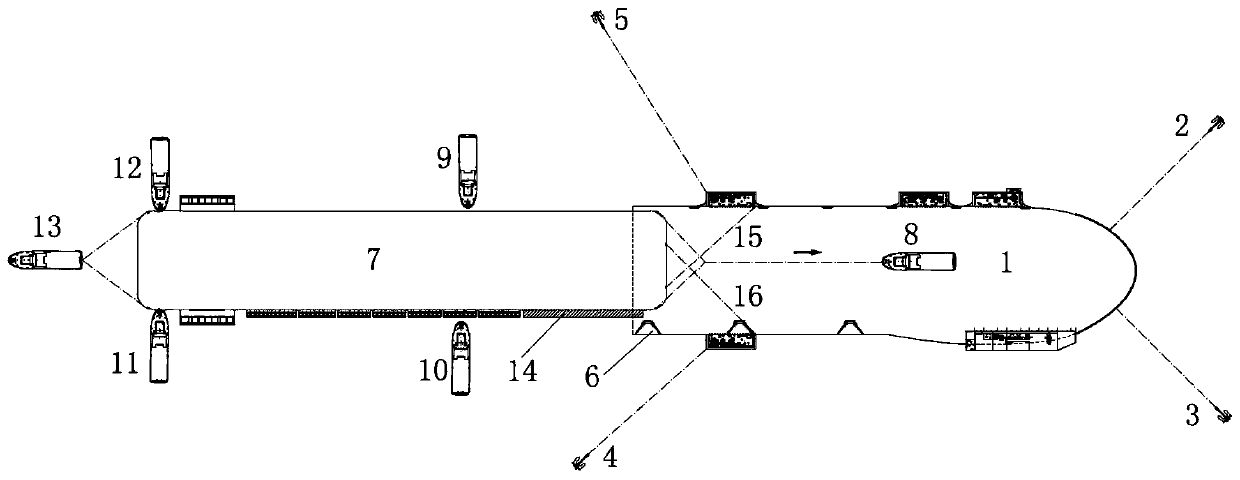

[0038] Such as Figure 1 to Figure 4 As shown, the dry towing transportation and floating process of the floating production, storage and unloading device of the present invention adopts the following steps:

[0039] The first step is the preparation before loading of semi-submersible vessel 1, such as figure 1 Shown, including:

[0040] (1) According to the size of the outer side of the floating production storage and unloading device 7 to be loaded, the guide device welded in advance on the deck 1 of the semi-submersible vessel will assist the floating production storage and unloading device to be loaded along a straight line to prevent deviation; Floating production, storage and unloading equipment is arranged with sleepers on the bottom ribs of the ship to ensure that the sleepers face the bottom ribs after loading, and the number of sleepers is proportional to the weight of the floating production, storage and unloading device to be loaded;

[0041] (2) Determine the loading op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com