Garbage classification treatment equipment and garbage can applying same

A processing equipment and garbage sorting technology, which is applied in the direction of garbage transmission, garbage collection, loading/unloading, etc., can solve the problems of easy filling of garbage bins, increased labor costs, and high equipment costs, so as to reduce the effective height and facilitate garbage placement. The effect of increasing throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the accompanying drawings and examples, and the embodiments of the present invention include but not limited to the following examples.

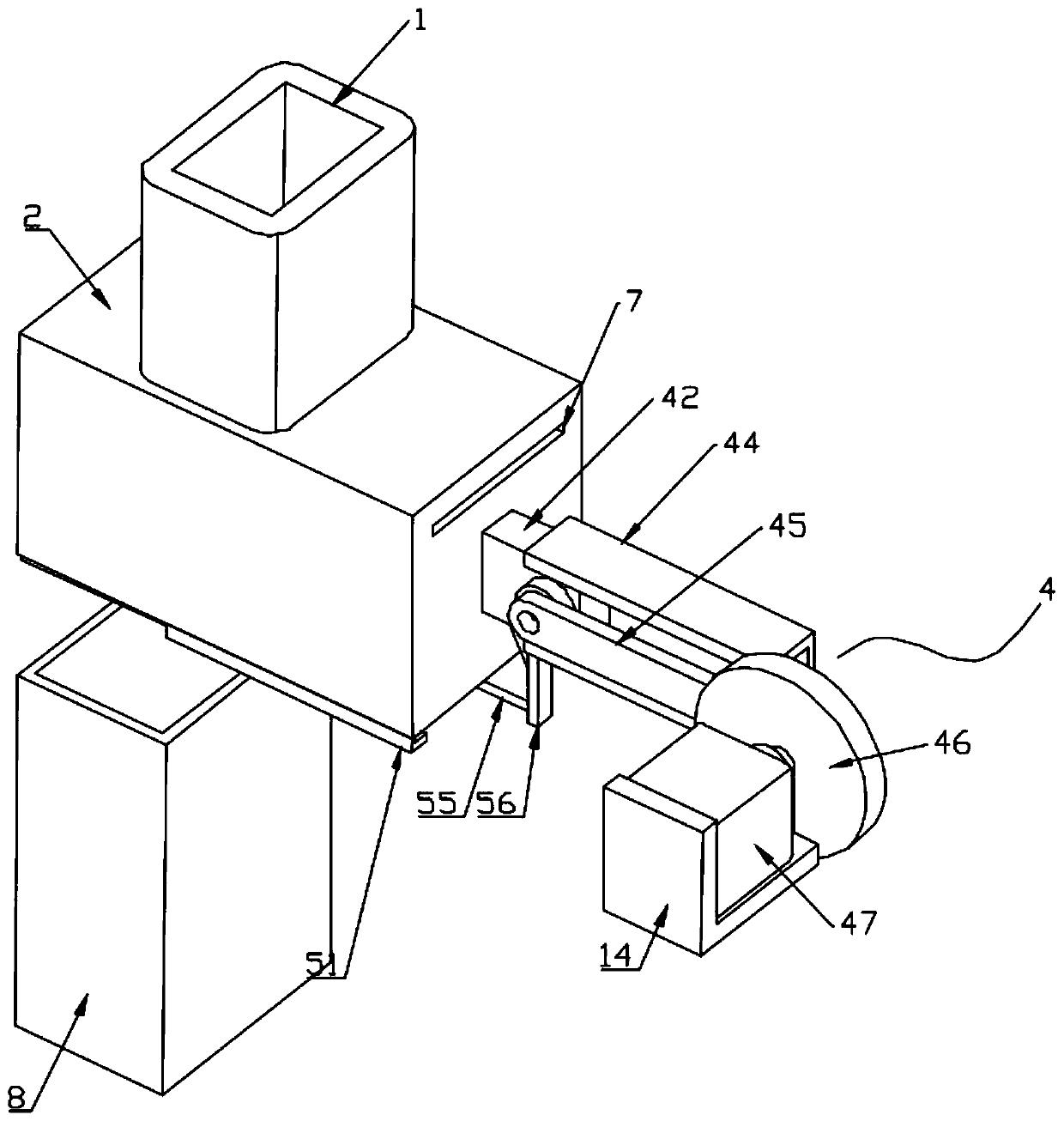

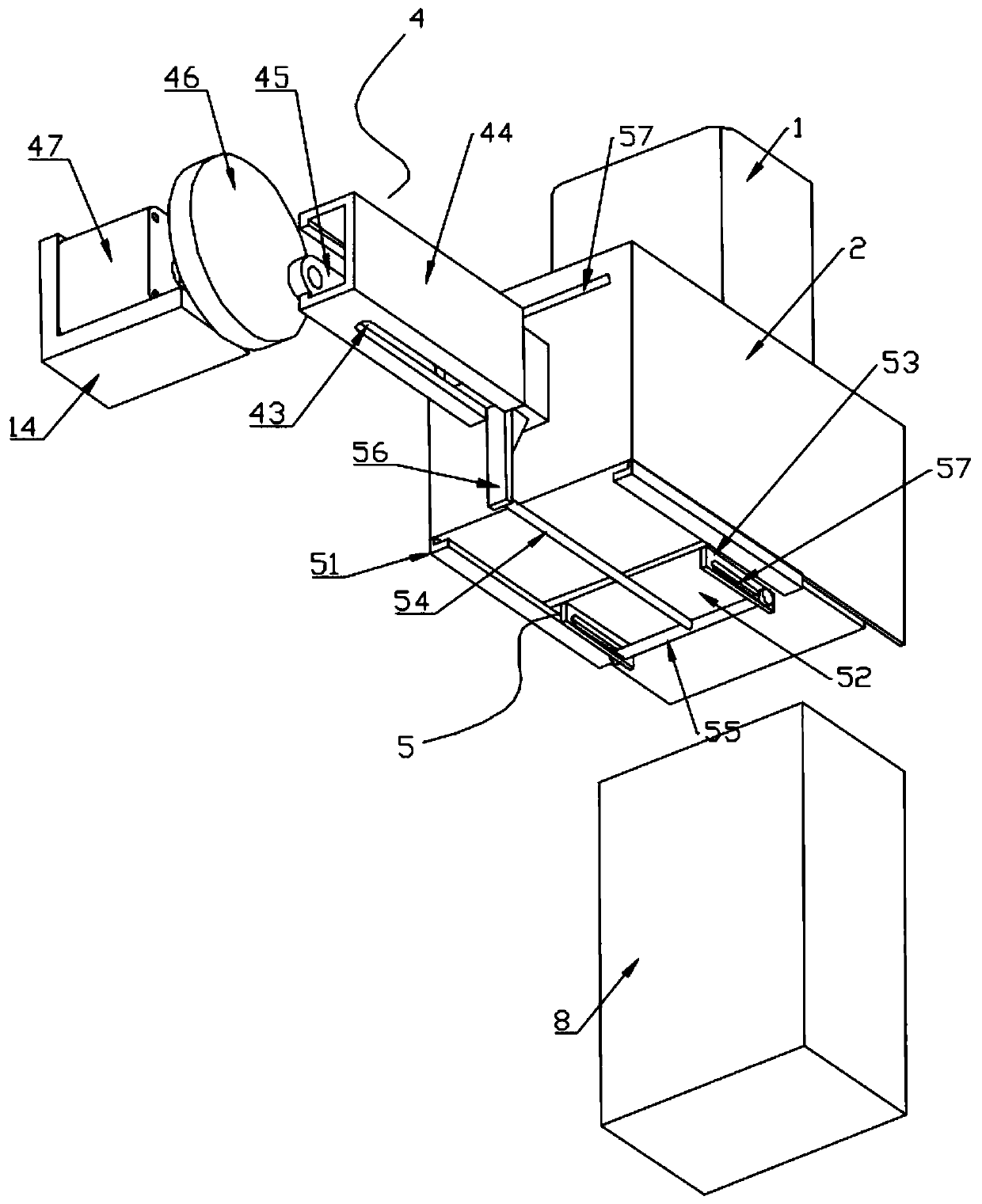

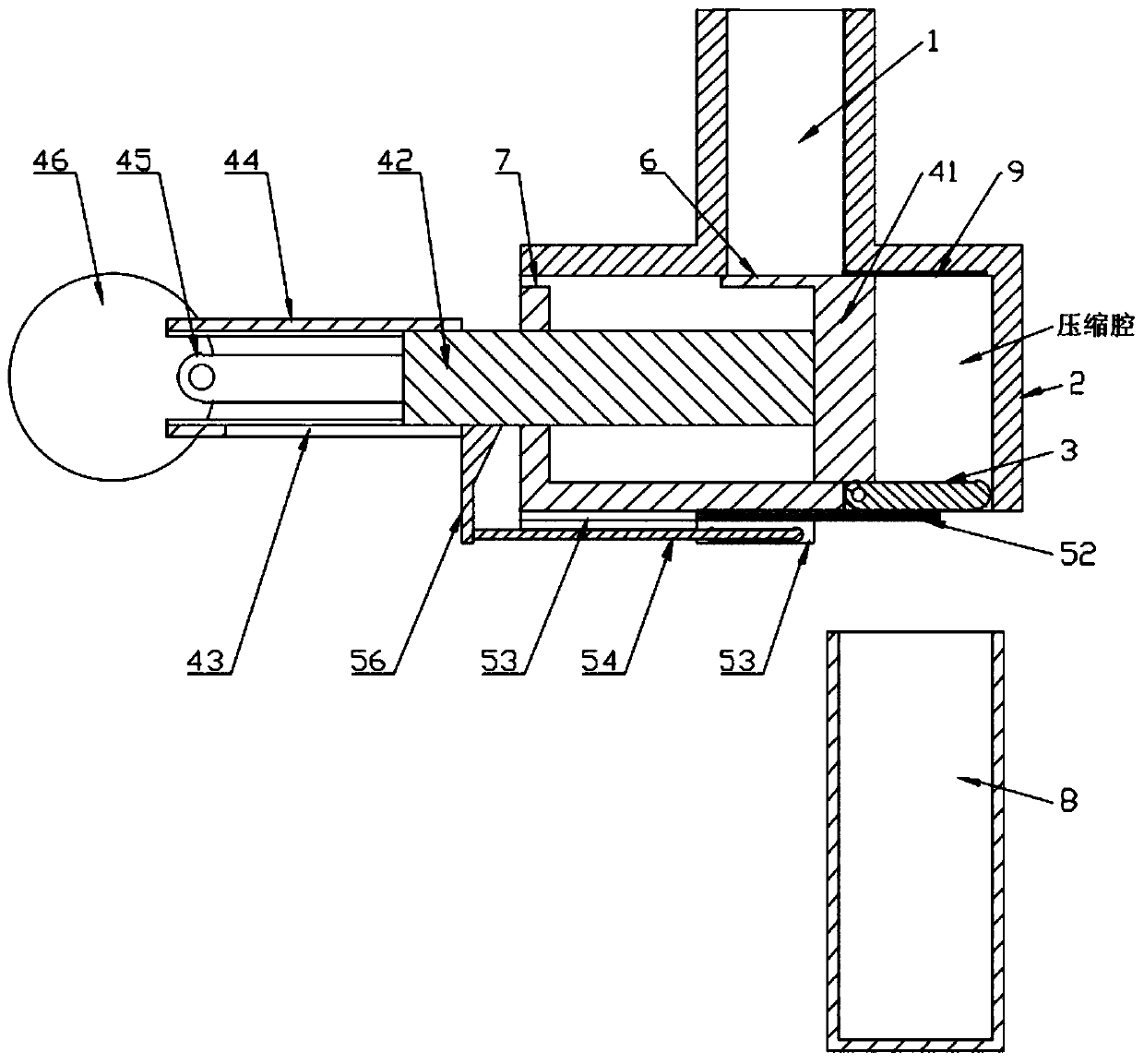

[0026] Such as Figure 1 to Figure 6 As shown, a kind of waste sorting processing equipment includes a feeding channel 1, a piston barrel 2, a compression mechanism 4, a blanking plate 3 and an opening and closing mechanism 5, and the feeding channel 1 is arranged on the top of the piston barrel 2;

[0027] The compression mechanism 4 is used to realize the compression molding of garbage, which specifically includes a piston 41, a piston rod 42, a sliding sleeve 44, a connecting rod 45, a driving wheel 46 and a motor 47. The piston 41 is slidably connected in the piston barrel 2, One end of the piston rod 42 is connected to the piston 41 and its other end is slidably connected in the sliding sleeve 44. The side of the piston rod 42 at one end of the sliding sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com