A fast, short-flow and low-emission dyeing process for rayon cheese

A cheese, short process technology, applied in the field of rayon dyeing, can solve the problems of shortening the process time and low efficiency of the rayon process, and achieve the effect of reducing the degree of unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

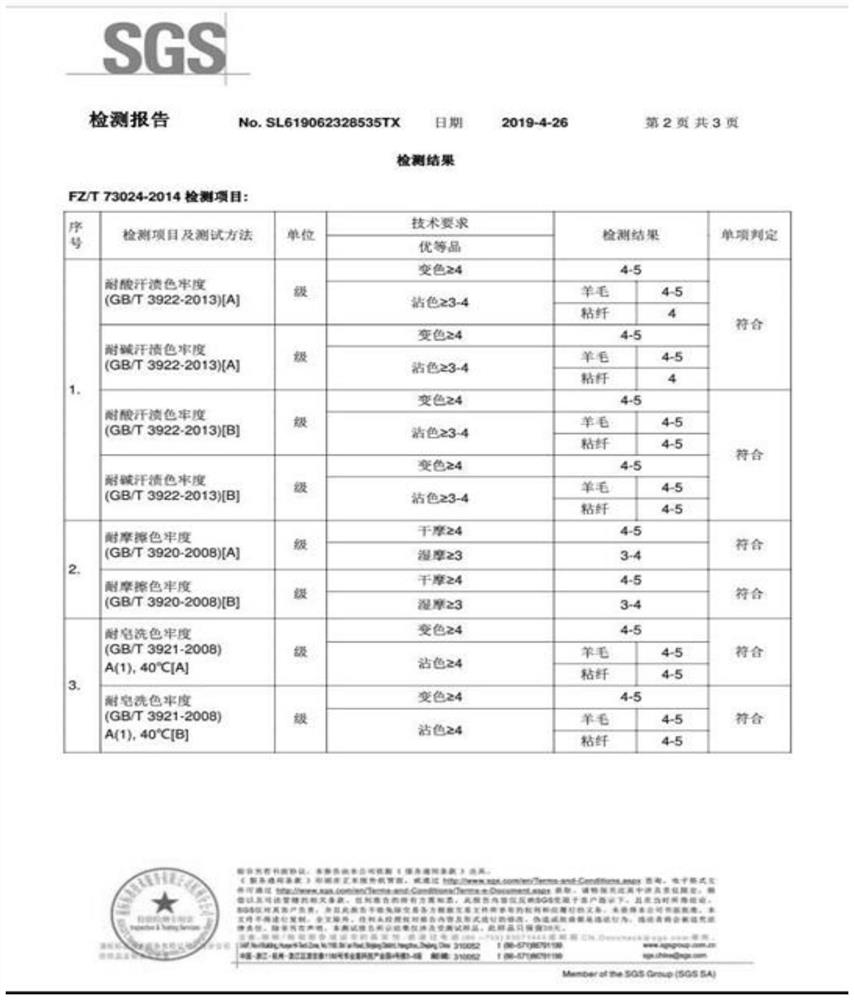

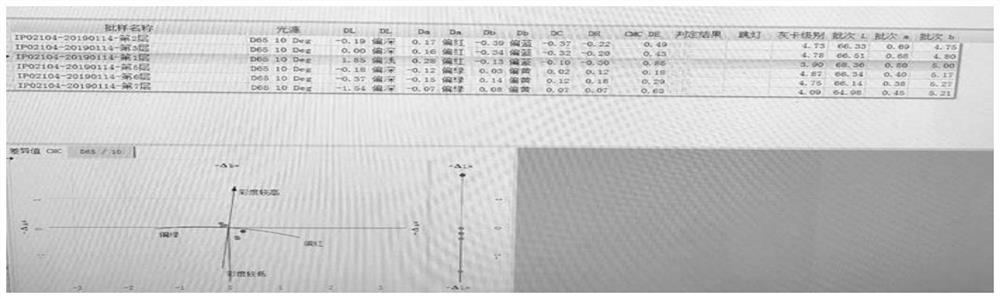

Image

Examples

Embodiment 1

[0041] A fast, short-flow and low-emission dyeing process for rayon cheese, comprising the following steps:

[0042] Step 1. Degreasing by dispersion and penetration: Add 1.0g / L dispersant, 2.0g / L dispersant NNO and 1g / L acetic acid, keep warm at 100°C for 10min, and control the pH value at 5.5;

[0043] Step 2. Dyeing: After degreasing, cool down to 60°C for dyeing or directly drain and then add water for dyeing. Specific dyeing operation: add anionic dispersant 0.5g / L, diffusing agent NNO1.0g / L, dye 1%owf, and then Add 5g / L of soda ash, with 0.8g / L of substitute alkali; or add it together with dyes for solid coloring, and keep warm for 20min at 60°C according to different colors or dyes; when dyeing, the inside and outside of the package is dyed The pressure difference of the liquid is controlled at 3.0bar; the pump speed of the main pump cycle is 80% of the rated speed, and the frequency is 47.5HZ;

[0044] Step 3. Post-treatment: The light-colored post-treatment process i...

Embodiment 2

[0046] A fast, short-flow and low-emission dyeing process for rayon cheese, comprising the following steps:

[0047] Step 1. Degreasing by dispersing and penetrating: add dispersant 0.5g / L, diffusing agent NNO 1.0g / L and acetic acid 2.0g / L, keep warm at 80°C for 30min, and control the pH value at 4;

[0048] Step 2. Dyeing: After degreasing, cool down to 40°C for dyeing or directly drain and then add water for dyeing. Dyeing specific operation: add anionic dispersant 2.0g / L, diffusing agent NNO3.0g / L, dye 2%owf, and then Add 30g / L of soda ash, with 2.0g / L of substitute alkali; or add it together with dyes for solid coloring, and keep warm for 90 minutes at a temperature of 90°C according to different colors or dyes; when dyeing, the inside and outside of the package is dyed The pressure difference of the liquid is controlled at 2.0bar; the pump speed of the main pump cycle is 90% of the rated speed, and the frequency is 40HZ;

[0049] Step 3. Post-treatment: The post-treatmen...

Embodiment 3

[0051] A fast, short-flow and low-emission dyeing process for rayon cheese, comprising the following steps:

[0052] Step 1. Degreasing by dispersing and penetrating: Add 2.0g / L dispersant, 3.0g / L diffusing agent NNO and 1.5g / L acetic acid, keep warm at 85°C for 15min, and control the pH value at 4.5;

[0053] Step 2. Dyeing: After degreasing, cool down to 50°C for dyeing or directly drain water and then add water for dyeing. Specific dyeing operation: add anionic dispersant 1.0g / L, diffusing agent NNO2.5g / L, dye 2%owf, and then Add 7g / L soda ash, with 0.5g / L substitute alkali; or add it together with dyes for solid coloring, and keep warm for 85min at 65°C according to different colors or dyes; when dyeing, the inside and outside of the package is dyed The pressure difference of the liquid is controlled at 1.0 bar; the pump speed of the main pump cycle is 95% of the rated speed, and the frequency is 47.5HZ;

[0054] Step 3. Post-treatment: After dark color, the post-treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com