Waterstop structure at junctions of occlusive piles and diaphragm wall

A technology of occlusal piles and ground-connected walls, which is applied in the field of construction engineering, can solve problems such as the difficulty of plugging leaks, affecting the safety of foundation pits and surrounding environments, and achieve the goals of enhancing stability and safety, and improving waterproof and anti-leakage performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

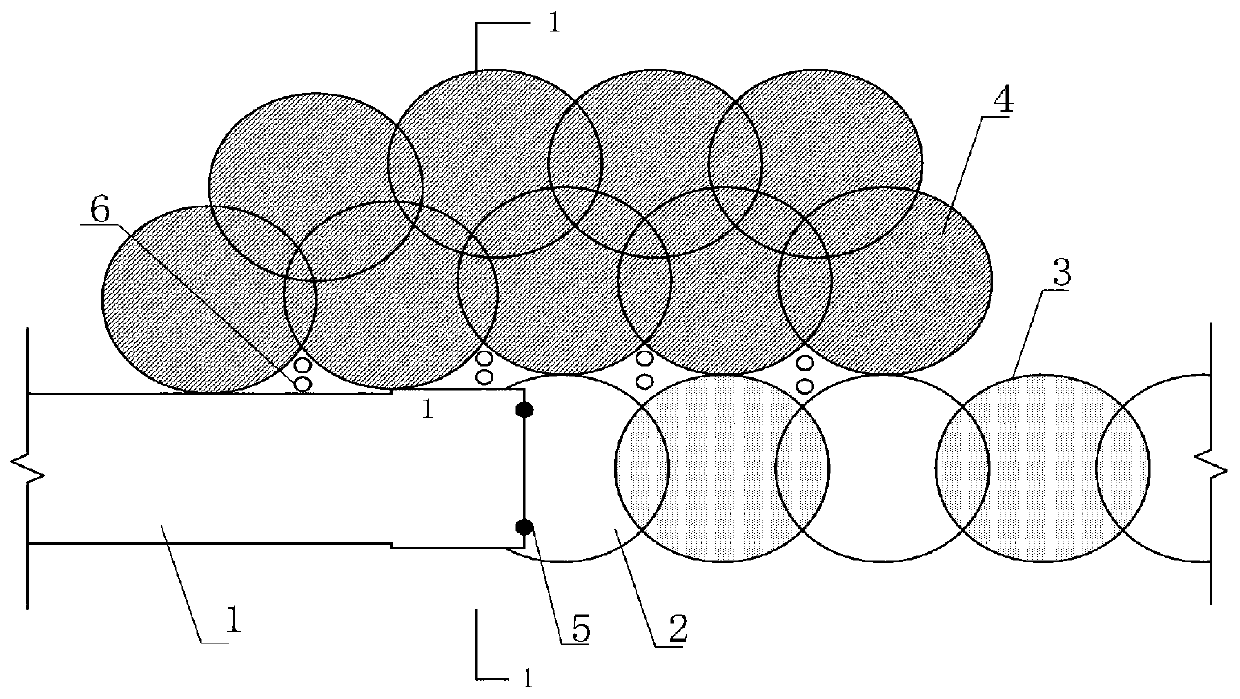

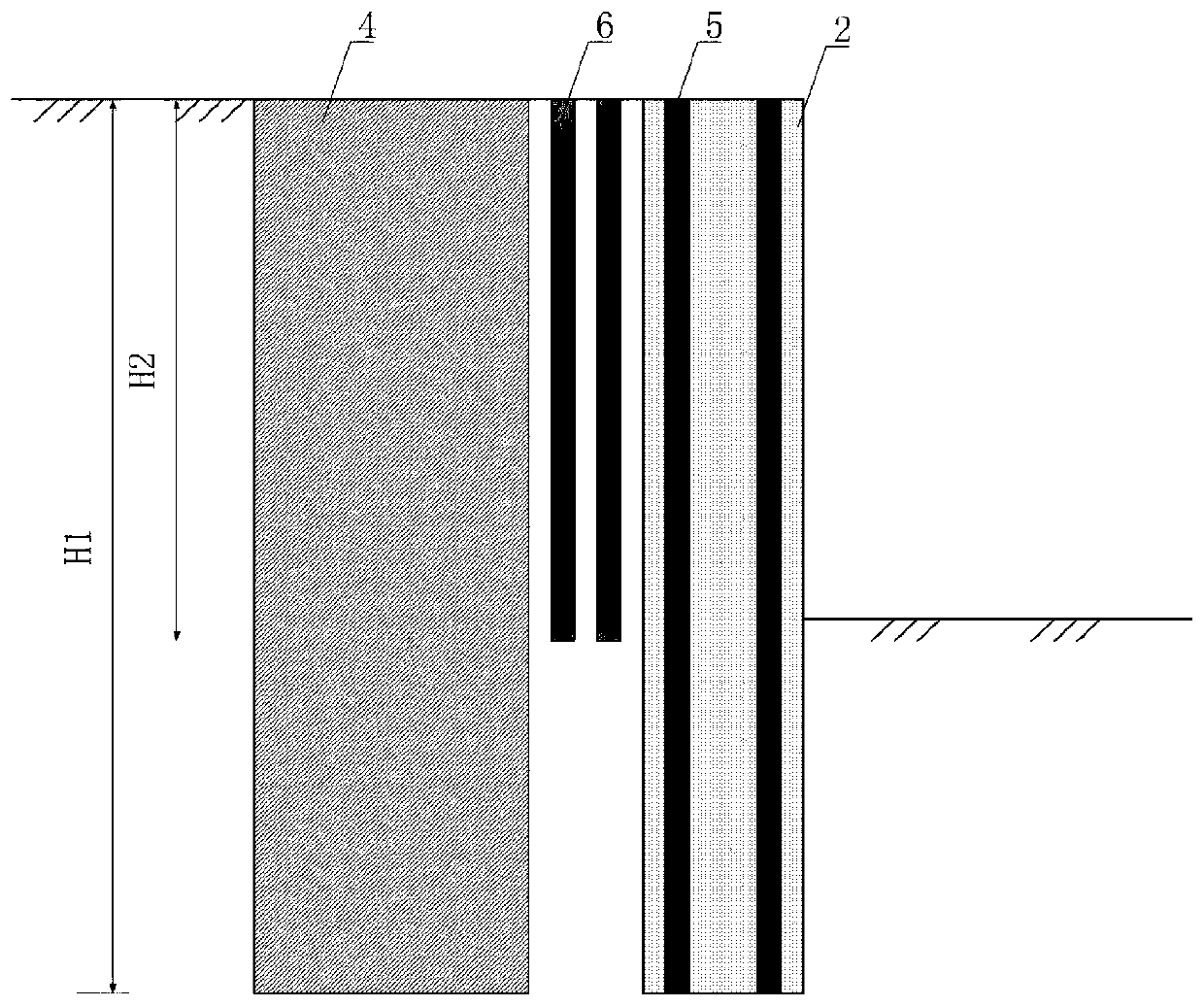

[0032]The main structure of the water-stop structure at the joint between the occlusal pile and the ground connection wall in this embodiment includes the ground connection wall 1, the occlusion pile 2, the occlusion pile 3, the rotary spray pile 4, the steel flower pipe 5 and the grouting pipe 6. The occlusal piles and the occlusal piles 3 and the occlusal piles 2 are arranged at intervals, interlocking to form an occlusal pile, the ground connection wall 1 is occluded with the adjacent occlusal pile 2, and the buried depth of the underground diaphragm wall 1 is the same as that of the adjacent occlusal pile 2. The burial depth is the same; the steel flower tube 5 is welded on the reinforcement cage on the adjacent side of the ground connection wall 1 and the adjacent occlusal pile 2, and the burial depth is the same as that of the ground connection wall 1; the grouting pipe 6 is buried in the occlusion pile 2 and the ground connection wall 1 outside the joint, the buried dept...

Embodiment 2

[0035] In this embodiment, the water-stopping structure at the joint between the occlusal pile and the ground wall described in Example 1 is applied to the joint between the occlusal pile and the underground diaphragm wall in a certain subway station, and the water-stop at the joint between the occlusal pile and the ground wall The main structure of the structure includes the ground connection wall 1, the wall thickness is 800mm, the width is 6.0m, and the buried depth is 26m. It is poured with C45 underwater concrete; The burial depth is 26m, poured with C25 ultra-retarded concrete; 3 occlusal piles, 1000mm in diameter, 700mm away from adjacent piles, 300mm in occlusal, 26m deep, poured with C45 underwater concrete; 4 rotary grouting piles, 1000mm in diameter , with a buried depth of 26m, 4 rotary grouting piles interlocked by 300mm, tangent to the ground connection wall 1, occlusal pile 2, and occlusal pile 3, poured with ordinary Portland cement with a label of 42.5; steel f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com