Fabricated shear wall assembly and manufacturing method thereof

A shear wall and prefabricated technology, applied to walls, building components, building insulation materials, etc., can solve problems such as poor seismic performance of shear wall groups, and achieve the effect of meeting seismic requirements and improving connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present application will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

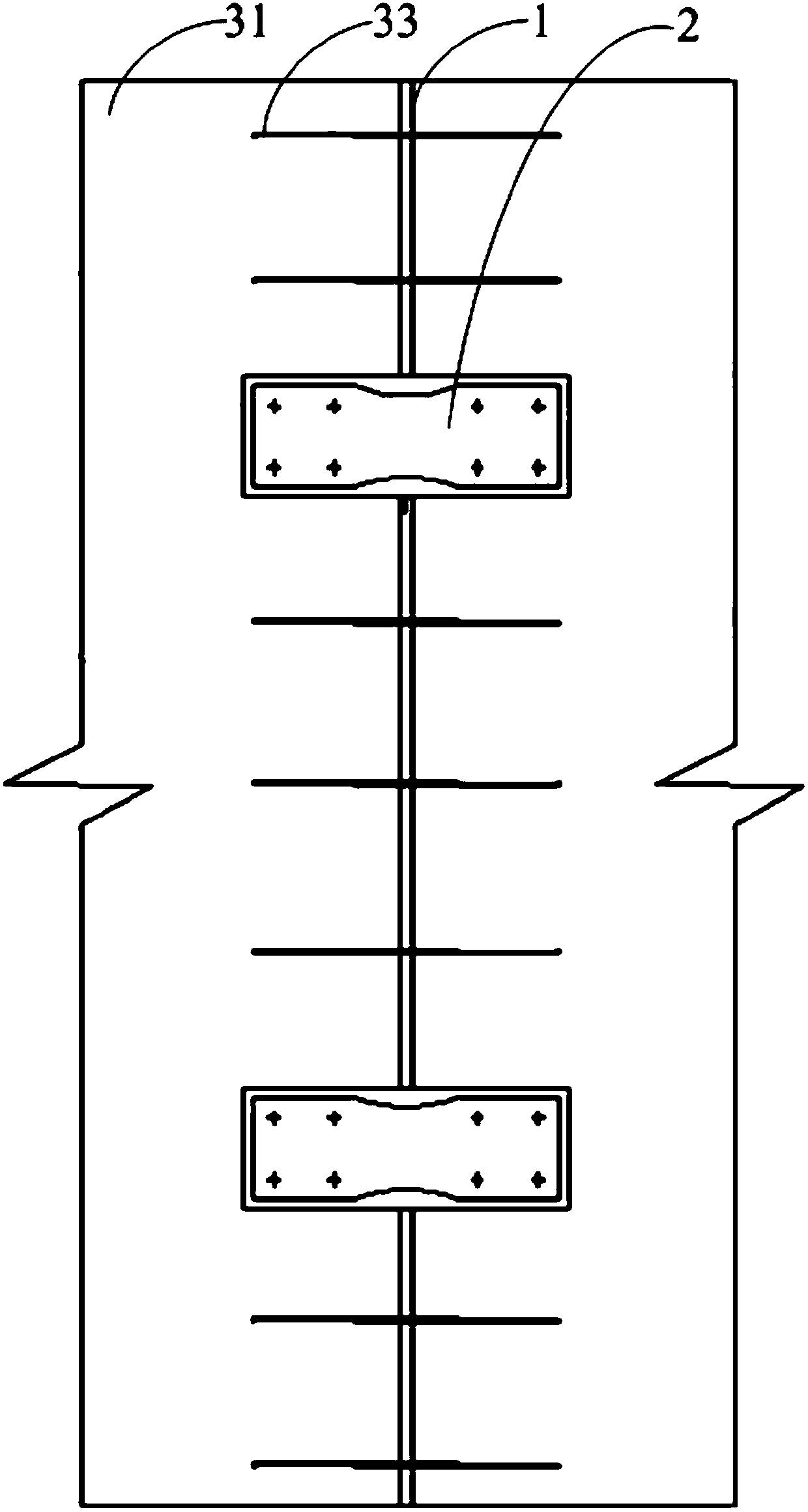

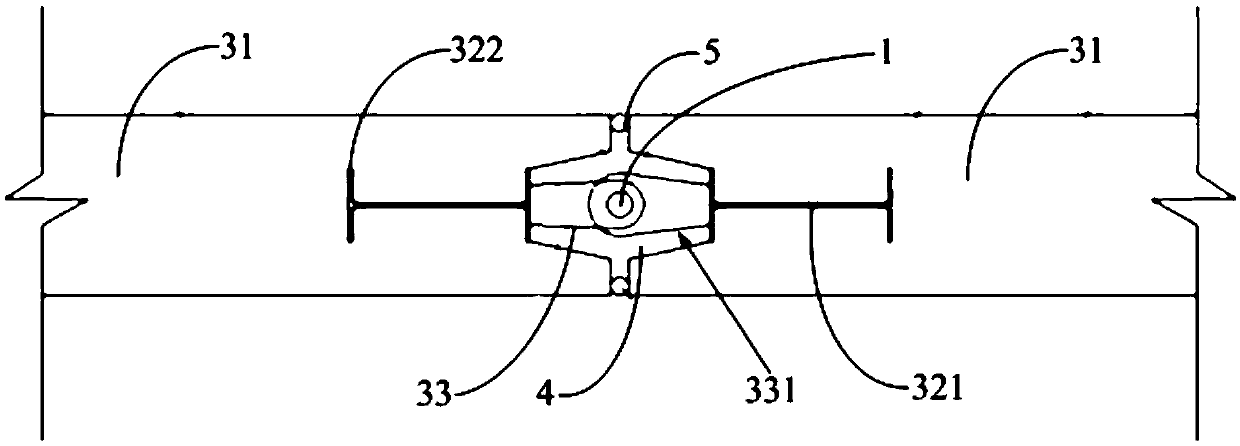

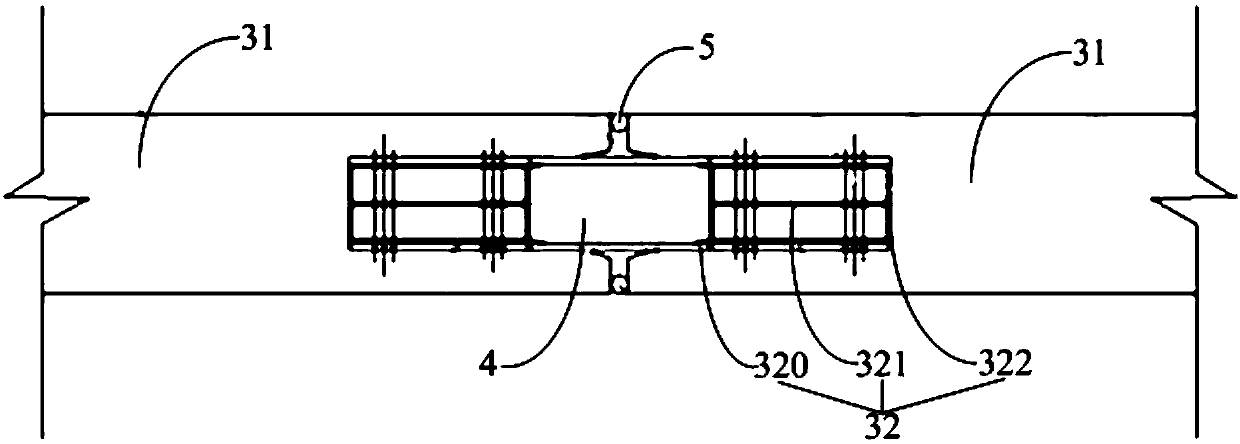

[0050] Such as Figure 1-3 As shown, the embodiment of the present application provides a prefabricated shear wall group, the prefabricated shear wall group includes a connecting bar 1, a connecting plate 2 and a plurality of shear walls 3, among the plurality of shear walls 3, The two adjacent shear walls 3 arranged along their own length direction are connected by connecting the ribs 1 and the connecting plates 2 at the same time, so as to improve the seismic capacity of the entire prefabricated shear wall group. Specifically, such as Figure 4As shown, the shear wall 3 includes a body of wall 31, a reinforcing member 32 and a connecting sleeve 33. The body of wall 31 can be formed by pouring concrete mortar, and its shape and size can be determined according to actual needs, and the type of concrete can be freely selecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com