High-dip-angle inside and outside reverse two-for-one twisting string and manufacturing method thereof

A manufacturing method and reverse technology, applied in stringed instruments, textiles, papermaking, instruments, etc., can solve the problems of loss, not being used by classical musicians, and need to be improved, and achieve the effect of good sound guiding effect, not easy to break strings, and wide range of sound.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical means adopted by the present invention to achieve the intended invention purpose are further described below in conjunction with the drawings and preferred embodiments of the present invention.

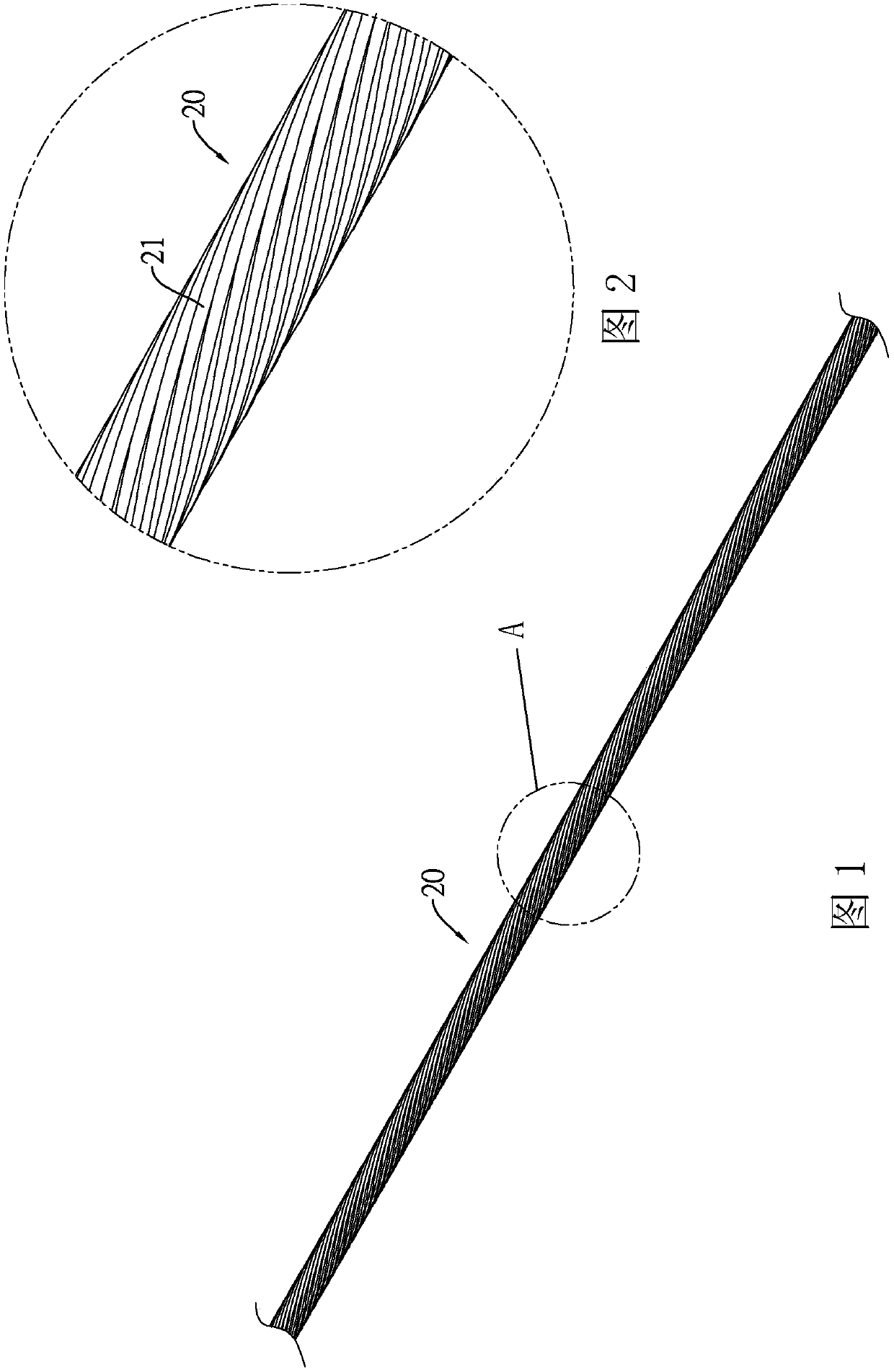

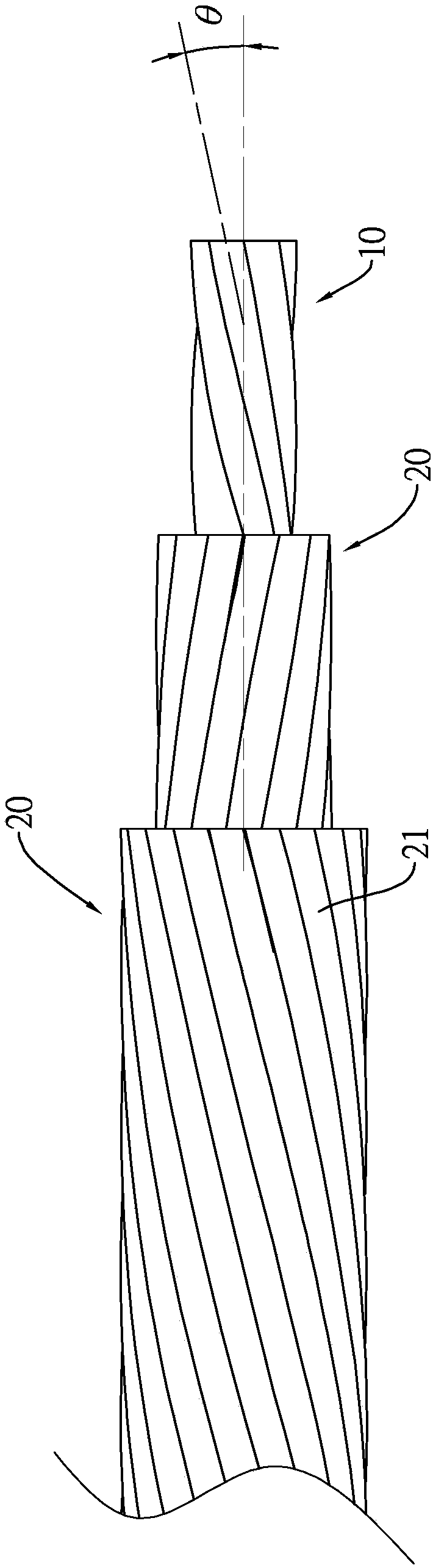

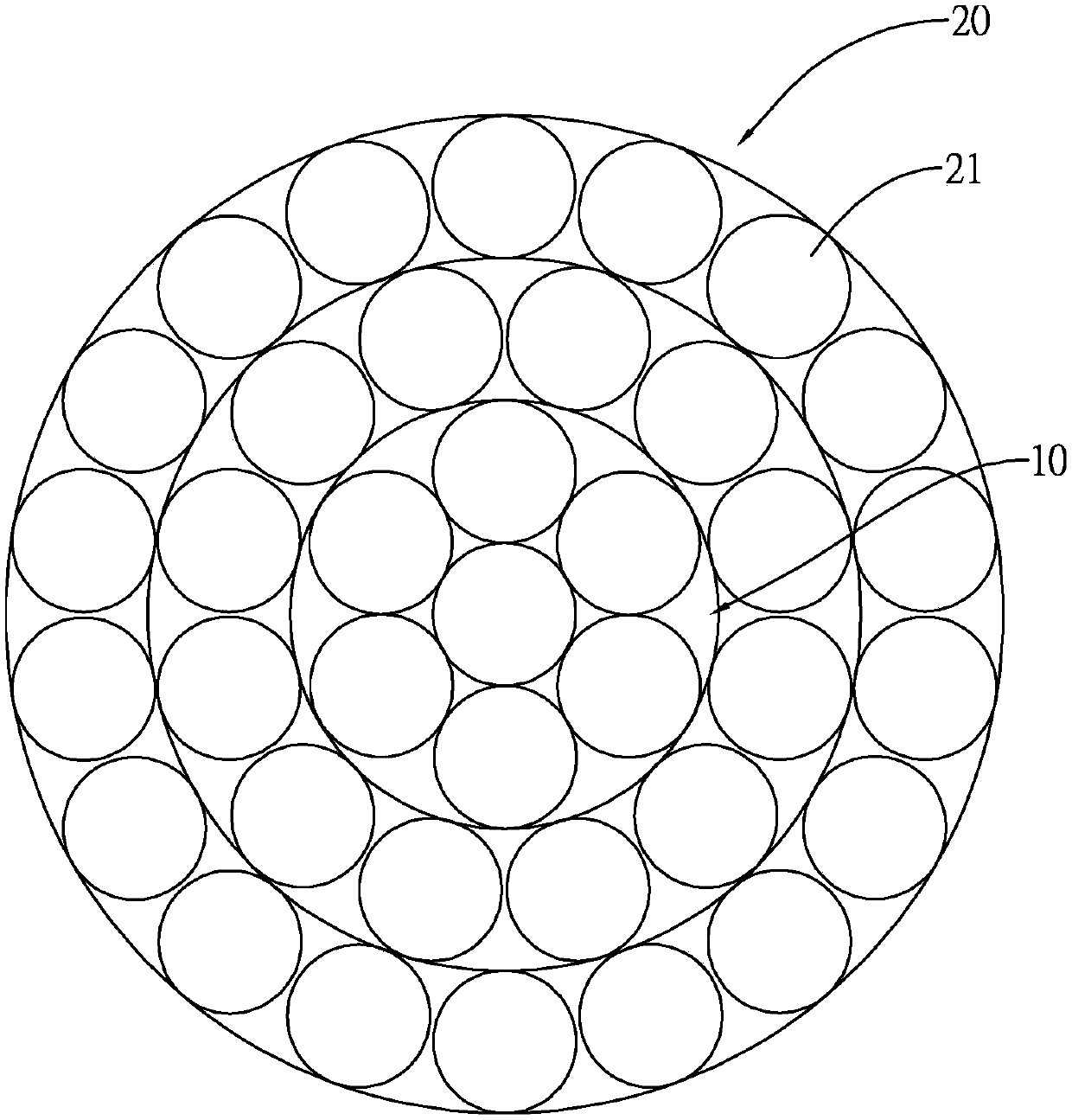

[0038] see figure 1 , figure 2 and image 3 As shown, the high-inclination inner and outer reverse two-for-one twist strings of the present invention include an axis line 10 and a plurality of coating layers 20 .

[0039] see image 3 and 4 As shown in the figure, in the present embodiment, the axis line 10 is a strand wound from one to seven strands, but the number of strands is not limited thereto, and each strand is wound with the center of the axis. The angle θ between them is between 10 and 30 degrees; that is to say, the axis line 10 is formed by intertwining and twisting one to seven single yarns. In addition, the material of the axis line 10 may be synthetic fiber, or a composite artificial medium material including polyester fiber and cotton, but i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap