Image sensor and method for forming image sensor

An image sensor and patterning technology, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of reducing manufacturing time and manufacturing costs, improve reliability, reduce the possibility of residues, and reduce process steps cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] As described in the background, there is a need to reduce manufacturing time and cost of existing image sensors, and to improve reliability of existing image sensors.

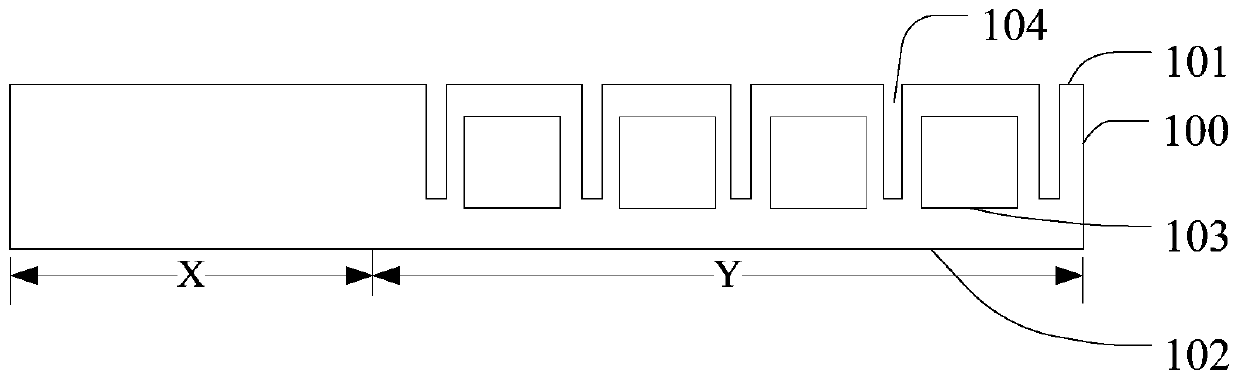

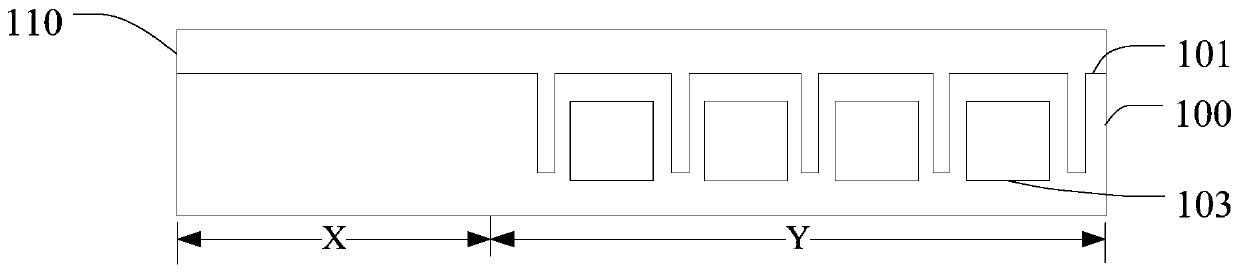

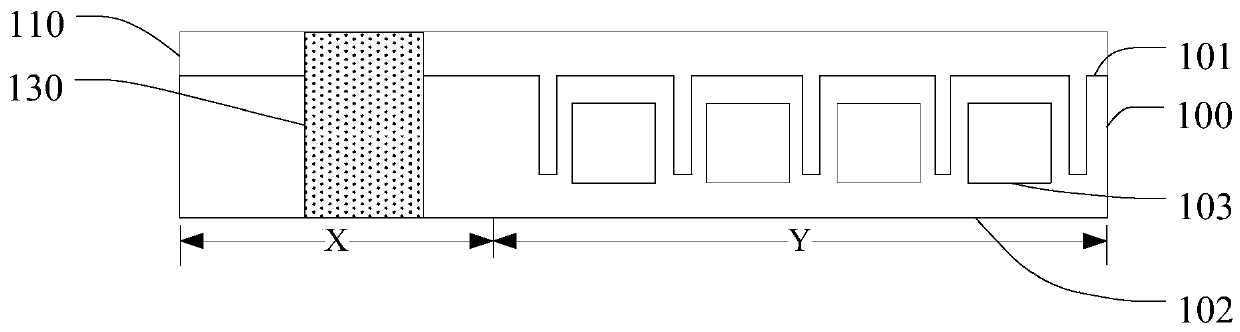

[0033] Figure 1 to Figure 6 It is a schematic cross-sectional structure diagram of an embodiment of the forming process of an image sensor.

[0034] Please refer to figure 1 , provide a substrate 100, the substrate 100 has an opposite first surface 101 and a second surface 102, the substrate 100 includes a region X and a region Y, the substrate 100 of the region Y has several photoelectric doping region 103 and a trench 104 surrounding the optoelectronic doped region 103 .

[0035] Please refer to figure 2 , filling the trench 104 to form an isolation structure (not shown); while forming the isolation structure, an initial anti-reflection layer 110 is formed on the surface of the first surface 101 .

[0036] Please refer to image 3 , forming a conductive plug 130 penetrating through the substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com