Polyphase fault-tolerant axial magnetic field motor

A technology of axial magnetic field and staggered type, which is applied in the direction of synchronous motor with stationary armature and rotating magnet, AC motor control, electrical components, etc., can solve the problem of increasing control cost, large input current, and motor volume should not be too large and other problems, to achieve the effect of high fault tolerance and lower current requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

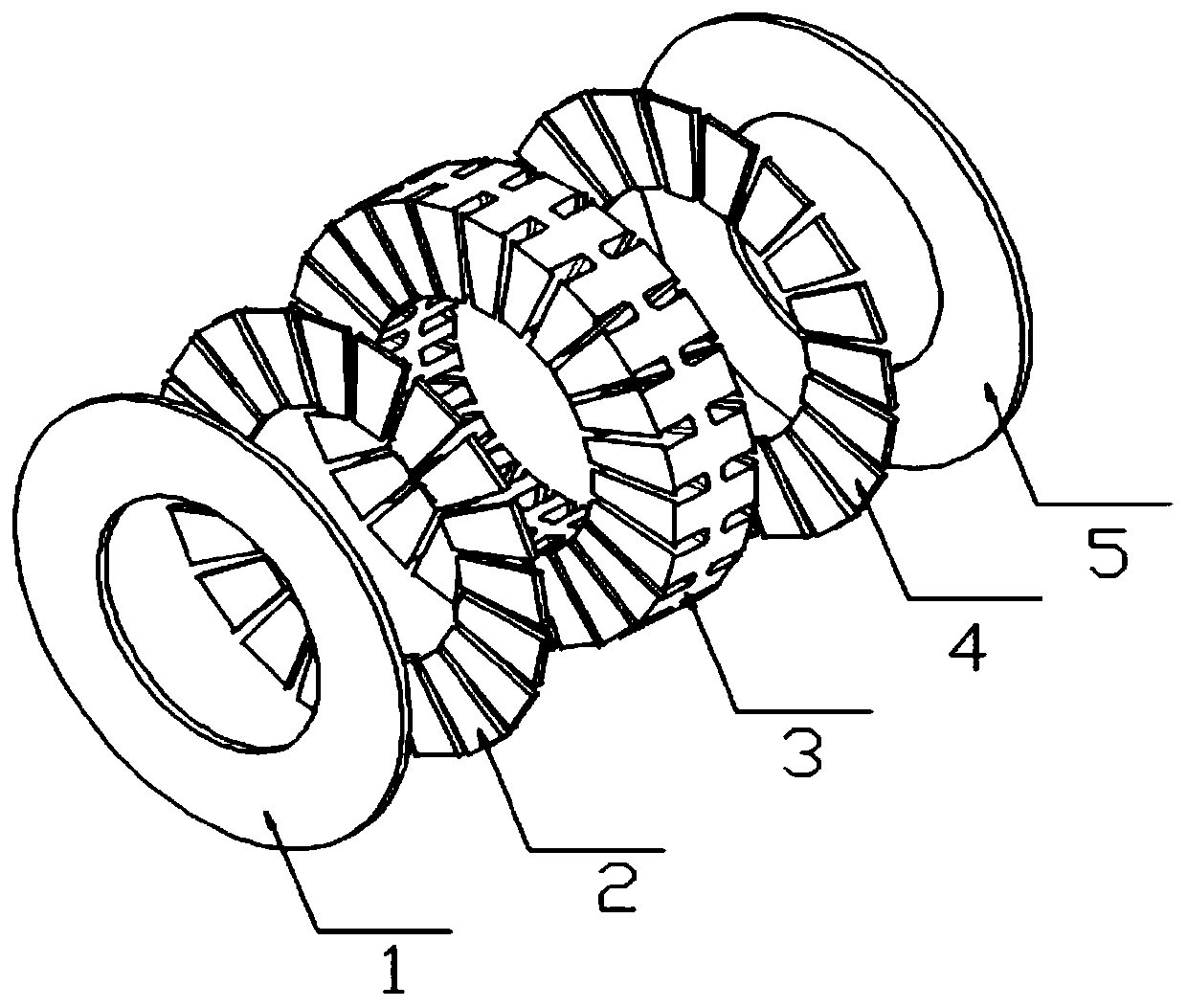

[0014] like figure 1 As shown, the multi-phase fault-tolerant axial field motor includes a first permanent magnet 2, a first rotor 1, a second permanent magnet 4, and a second rotor 5 installed and fixed on both sides of the stator 3 in sequence; There are two sets of windings with identical parameters and winding directions, and the two sets of windings are connected to the power supply in parallel.

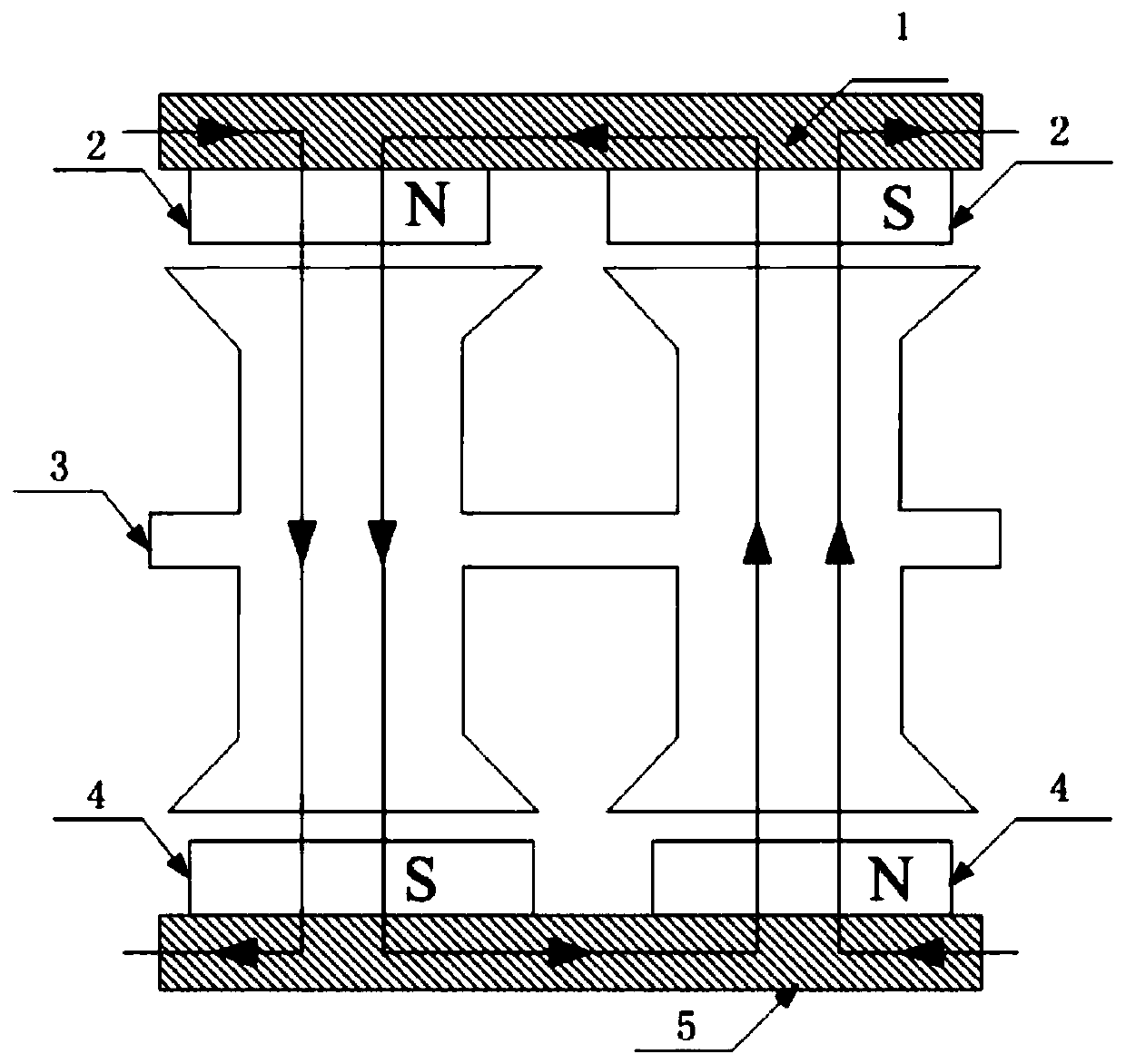

[0015] Further, the magnetic field starts from the N pole of the first permanent magnet 2, flows through the stator 3, the S pole of the second permanent magnet 4, the second rotor 5, the N pole of the second permanent magnet 4, the stator 3, the first permanent magnet 2 The S pole of the first rotor 1 returns to the N pole of the first permanent magnet 2.

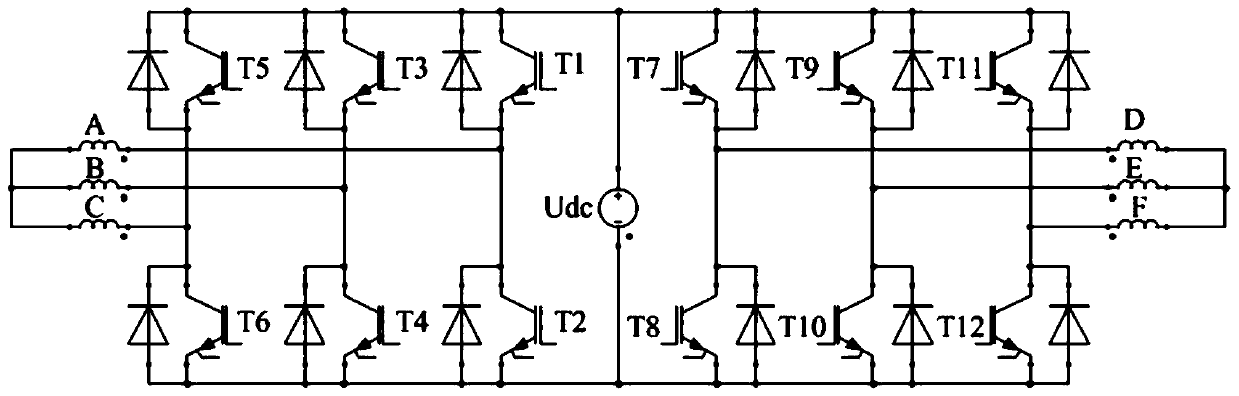

[0016] Further, after the first set of winding coils on the stator 3 are connected to the power tube T1, power t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com