Reinforcing cap for industrial detonator assembling and preparation method thereof

A production method and a technology for strengthening caps, which are applied to detonators, offensive equipment, sorting, etc., to achieve the effects of improving bonding strength, enhancing restraint, and good pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the drawings and embodiments.

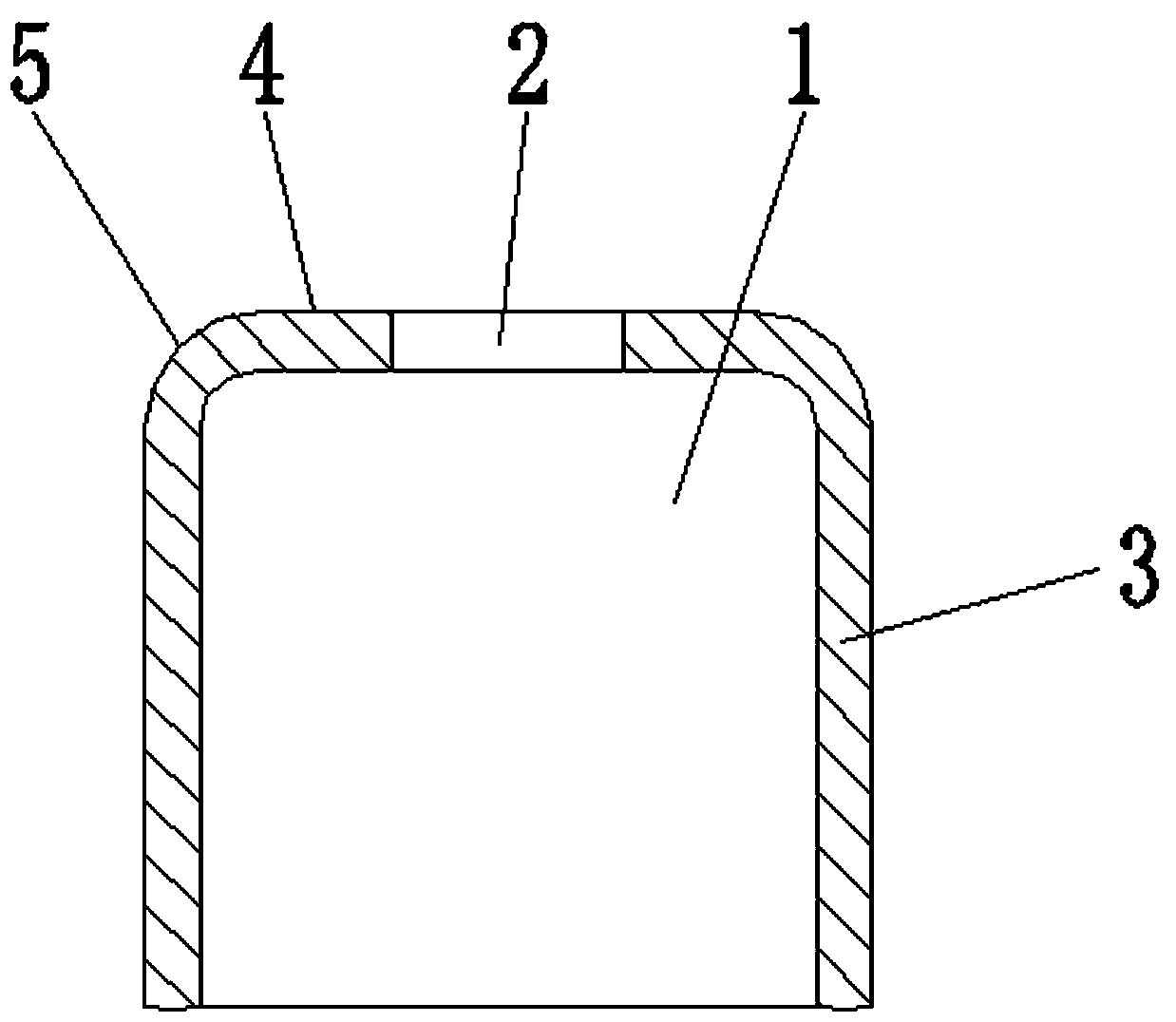

[0019] See figure 1 , A reinforced cap for assembling industrial detonators, including a cylindrical cap body 1, the cap body 1 is divided into a vertical side 3 and a horizontal side 4, the intersection of the vertical side 3 and the horizontal side 4 forms an arc angle with a radius of 0.5 mm 5. The thickness of the vertical side 3 and the horizontal side 4 is 0.5 mm, the cap body 1 is hollow, and it is made of 5 series of rust-proof aluminum with a hardness between 70-90. It is provided at the center of the top of the cap body 1. An opening 2 with a diameter of 2 mm±0.01 mm; the cap body 1 has a height of 6.8 mm and a diameter of 6.22 mm.

[0020] A manufacturing method of a reinforced cap for assembling industrial detonators, the manufacturing process is as follows:

[0021] First, select 5 series of rust-proof aluminum materials with a hardness between 70-90, place ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com