In situ cultivation device, and method of high through-put separating and screening microorganism

A technology of in situ culture and microorganisms, applied in the directions of separating microorganisms, supporting/immobilizing microorganisms, and sampling methods of biological materials, etc., can solve problems such as hindering the development of microbial resources and research on the law of microbial life activities, and achieve the effect of high-efficiency separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

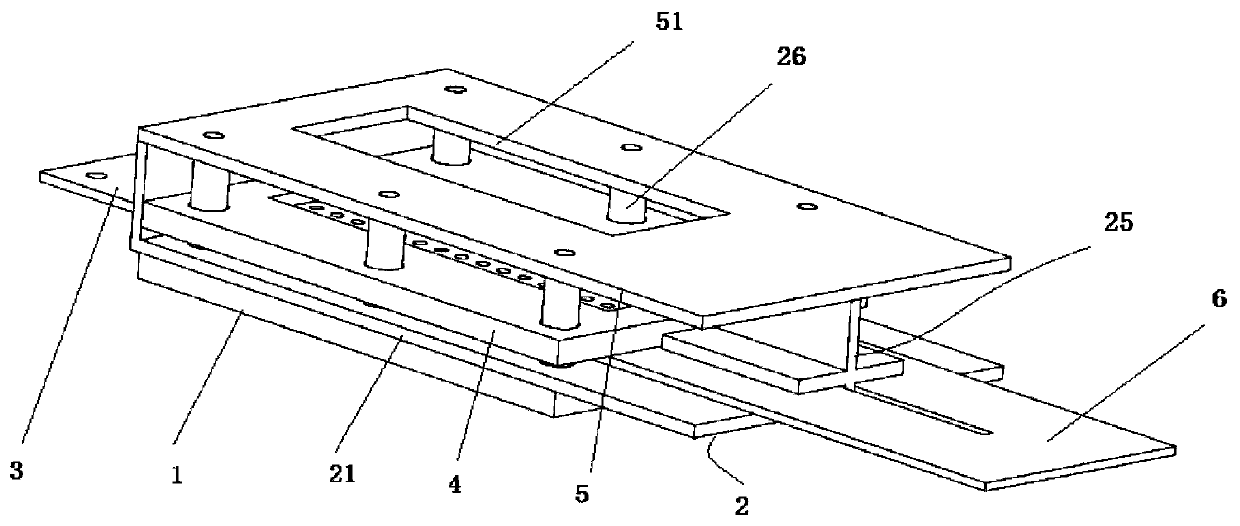

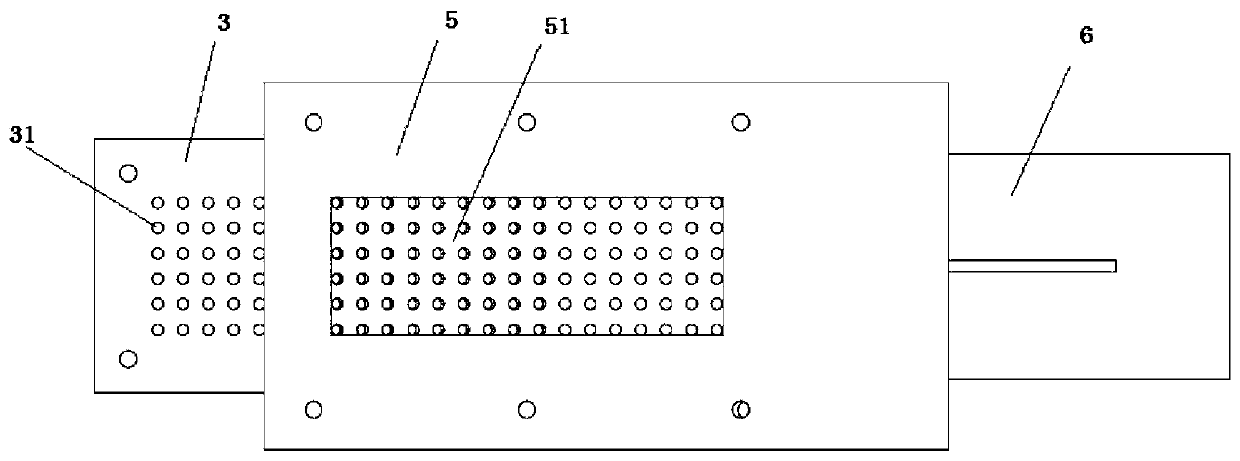

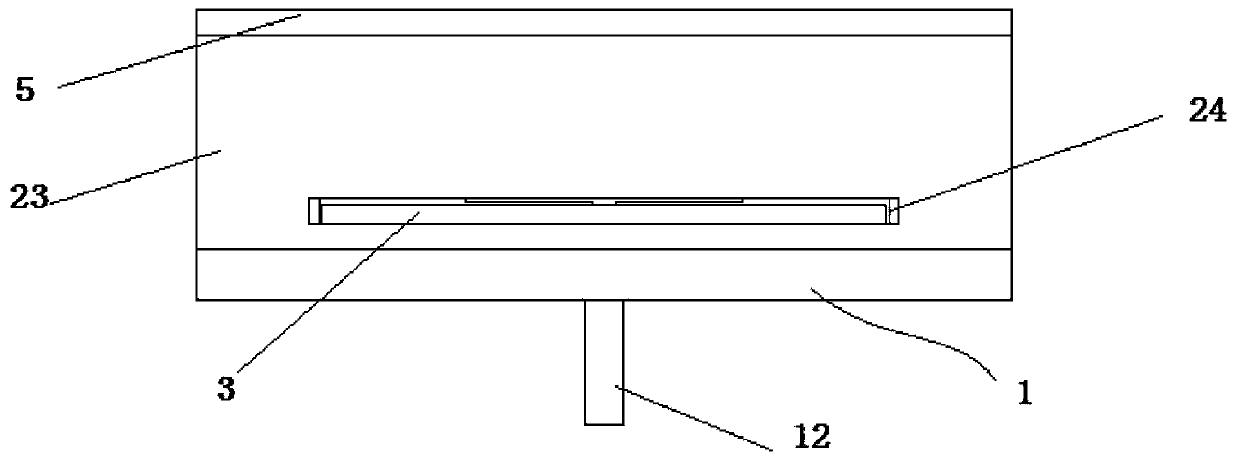

[0044] Such as Figure 1-6 , Figure 11 , Figure 12 As shown, the present invention provides a kind of in-situ culture device, and it comprises in-situ bacteria separation device, and in-situ bacteria separation device comprises:

[0045] A vacuum chassis 1, the upper part of which is formed with a vacuum groove 11, and the lower part is provided with a cylindrical ring 12 communicating with the vacuum groove 11;

[0046] The clamp lower layer 2 is fastened to the top of the vacuum chassis 1, and the bottom plate 21 of the clamp lower layer 2 is formed with a through hole 22 communicating with the vacuum groove 11;

[0047] The chip 3 is placed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com