Rocker arm type linkage turnover device of muck truck cover plate

A technology of a turning device and a muck truck, which is applied in the field of mechanical equipment, can solve the problems that the muck truck cannot make full use of the space of the box, occupy the front loading space of the box, reduce the effective volume of the box, etc., and achieve a stable front cover structure. , Good anti-overload and high loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

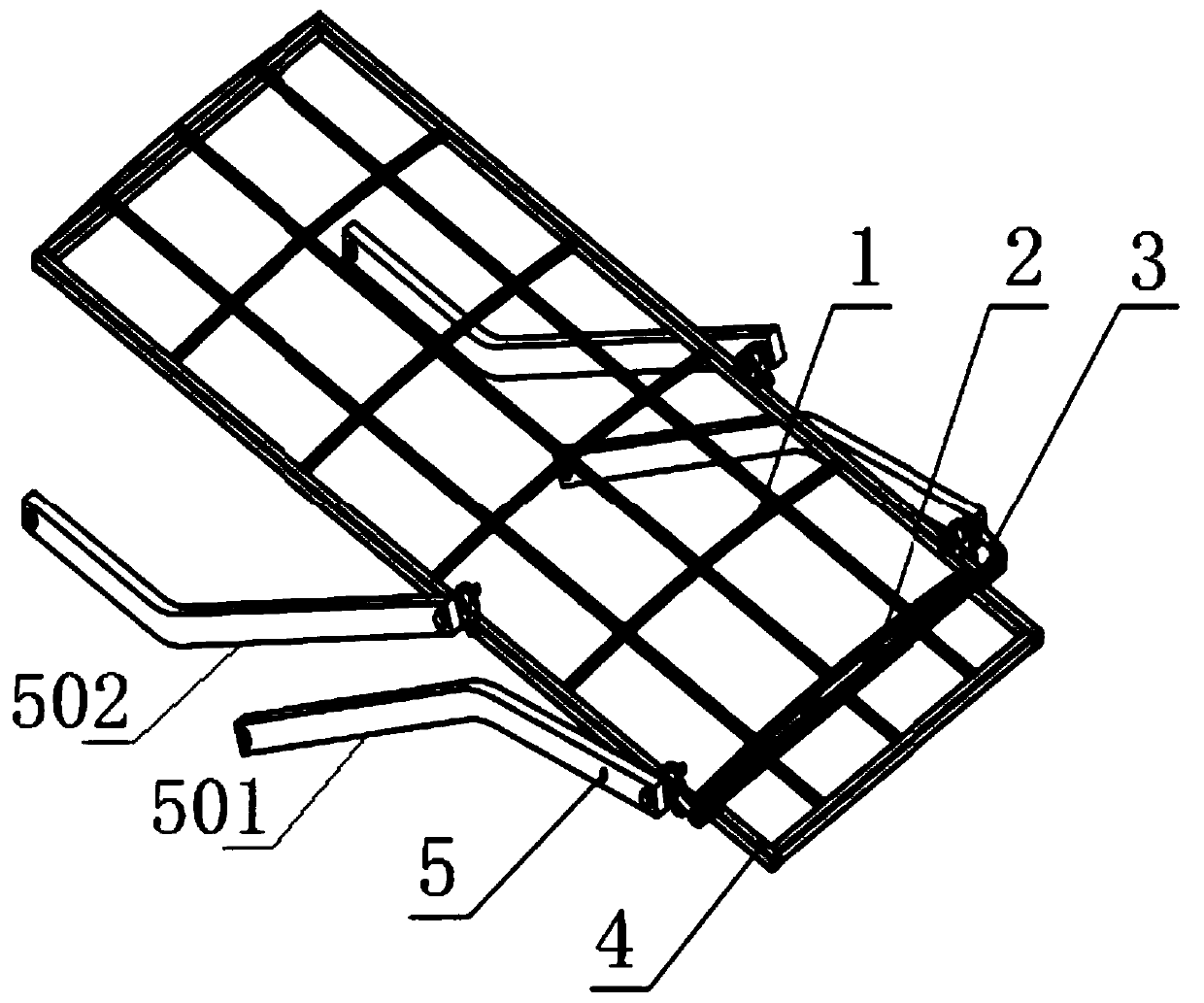

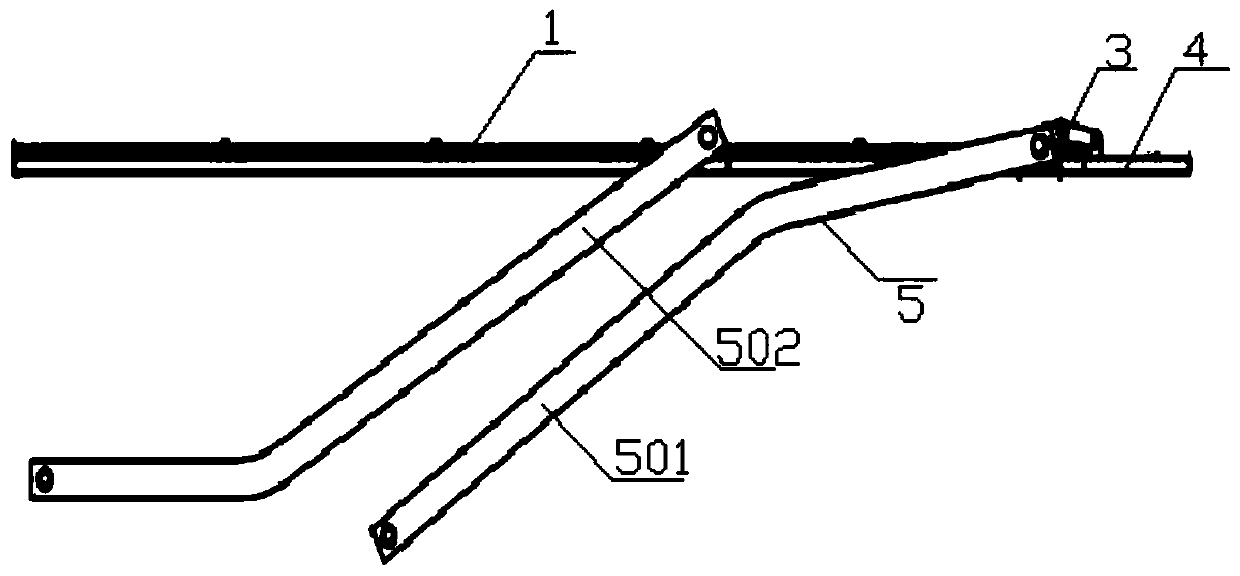

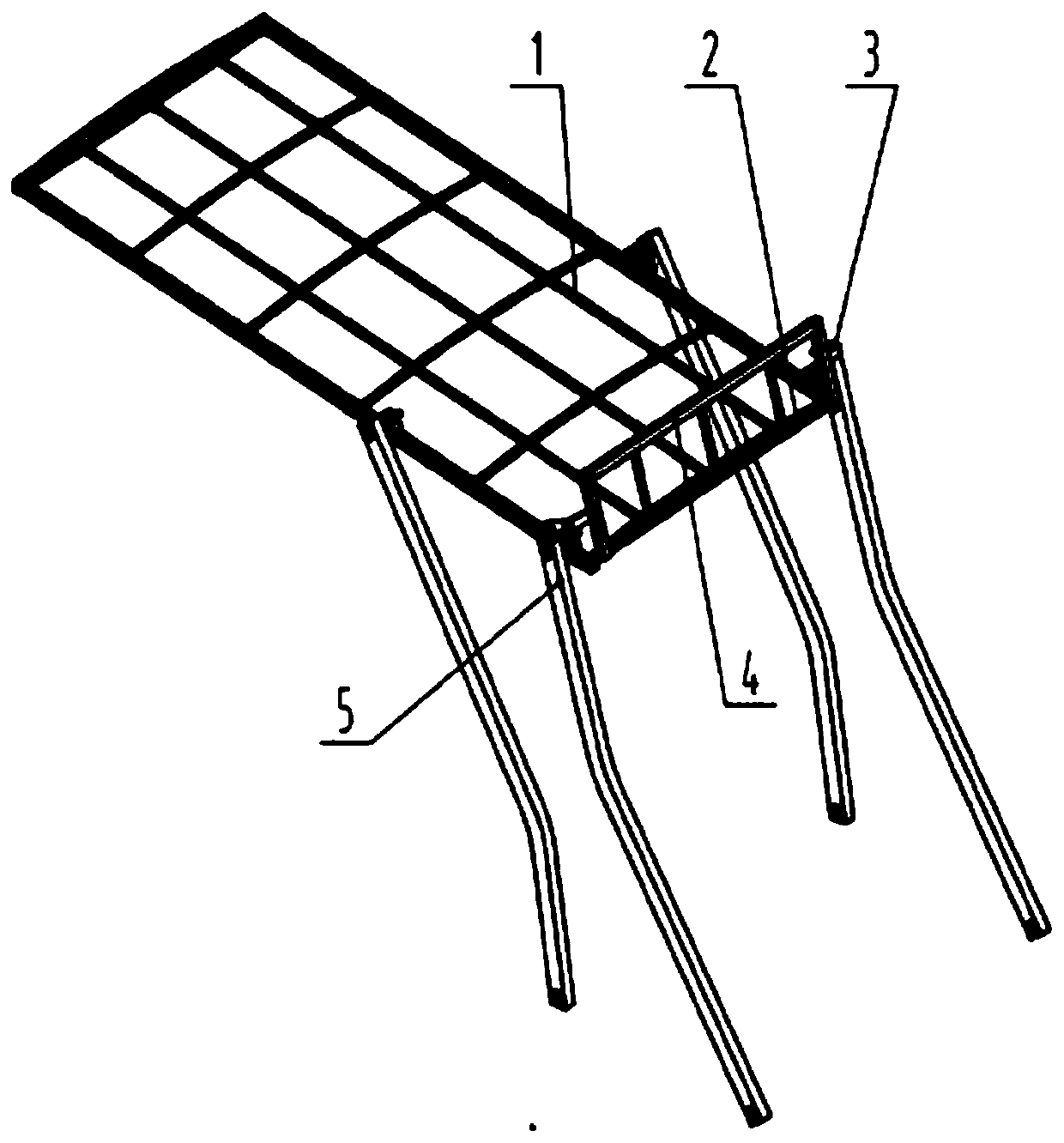

[0029] Such as Figure 1-6 As shown in the figure, a linkage overturning device for the cover plate of a rocker arm type muck truck includes a front cover 1, one end of the front cover 1 is rotated by a hinge 2 and a rear cover 4 is installed, and the left and right sides of the front cover 1 are along the front cover 1 A rocker arm 5 is symmetrically arranged on the central axis, and the rocker arm 5 is rotatably installed with the front cover 1. The rocker arm 5 includes a front rocker arm 501 close to the hinge 2, and the side of the front rocker arm 501 away from the hinge 2 is a rear rocker arm 502. The front rocker arm 501 is provided with a turning mechanism 3, the turning mechanism 3 includes a turning plate 301, the turning plate 301 is fixedly installed on the upper end of the front rocking arm 501, the turning plate 301 is rotatably equipped with a connecting plate 302, and the end of the connecting plate 302 is rotatably mounted. There is a fixed plate 303, and the...

Embodiment 2

[0035] Such as Figure 1-8 As shown in the figure, a linkage overturning device for the cover plate of a rocker arm type muck truck includes a front cover 1, one end of the front cover 1 is rotated by a hinge 2 and a rear cover 4 is installed, and the left and right sides of the front cover 1 are along the front cover 1 A rocker arm 5 is symmetrically arranged on the central axis, and the rocker arm 5 is rotatably installed with the front cover 1. The rocker arm 5 includes a front rocker arm 501 close to the hinge 2, and the side of the front rocker arm 501 away from the hinge 2 is a rear rocker arm 502. The front rocker arm 501 is provided with a turning mechanism 3, the turning mechanism 3 includes a turning plate 301, the turning plate 301 is fixedly installed on the upper end of the front rocking arm 501, the turning plate 301 is rotatably equipped with a connecting plate 302, and the end of the connecting plate 302 is rotatably mounted. There is a fixed plate 303, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com