A diesel filter with oil level control

A diesel filter and oil level control technology, which is applied in the direction of machines/engines, charging systems, liquid fuel feeders, etc., can solve the problem of air entering the oil circuit, and achieve improved connection sealing, good flow effect, Effect of increasing connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

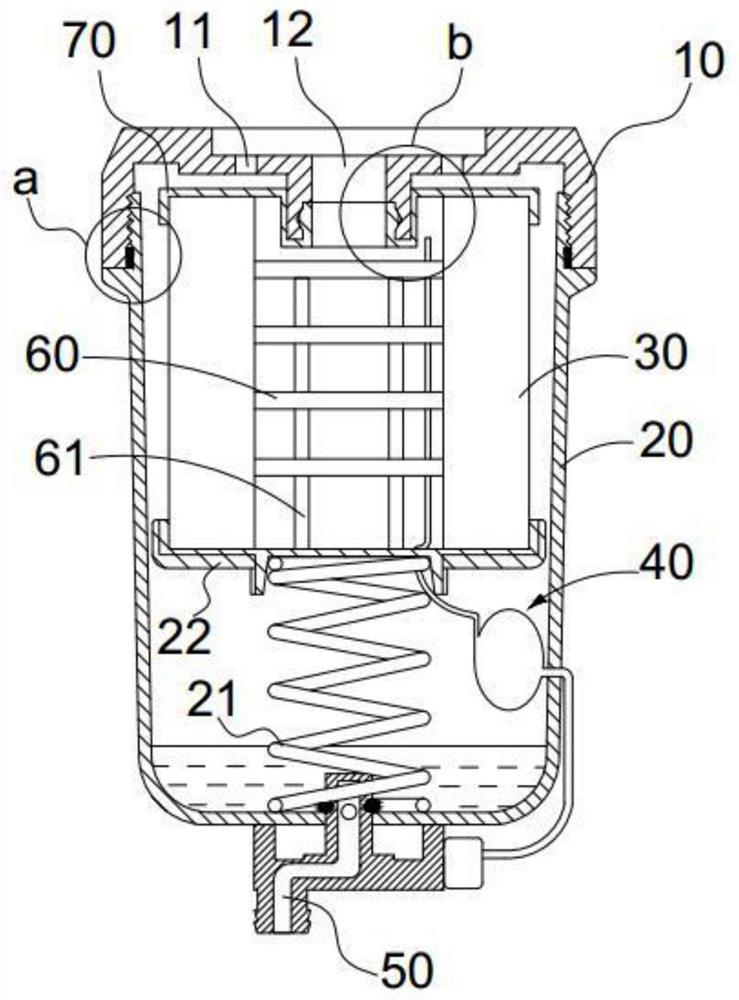

[0031] see Figure 1-8 As shown, a diesel filter with oil level control, including:

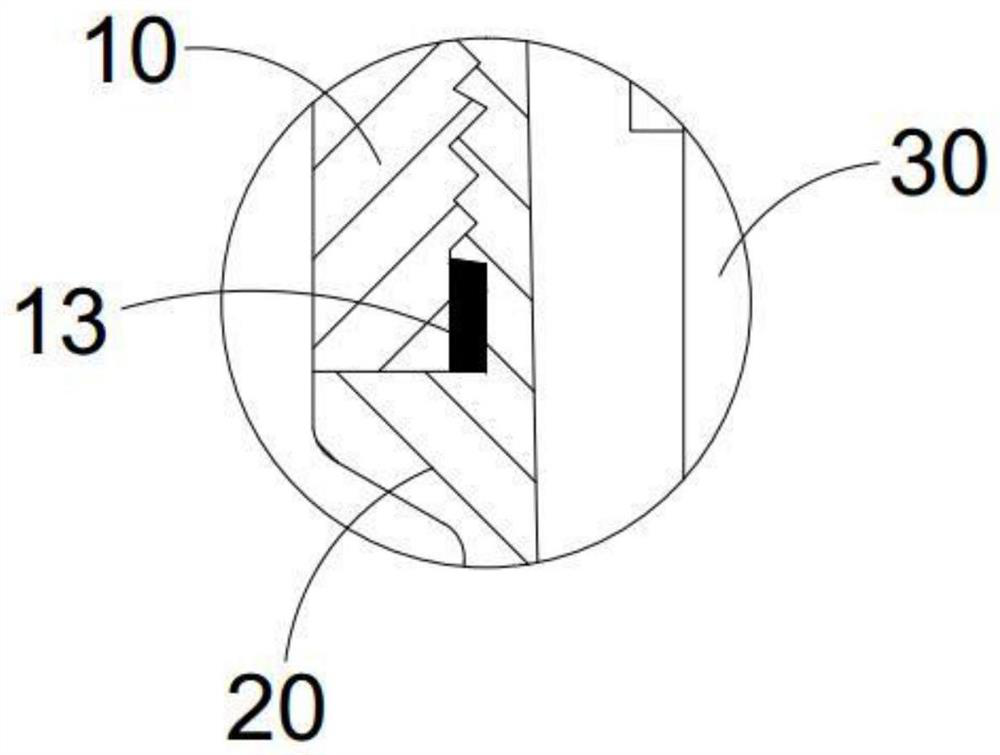

[0032] The housing 20, the port of the housing 20 is covered by the threaded cover plate 10, the threaded cover plate 10 has an oil inlet 11 for inputting fluid in the housing 20, and an oil outlet 12 for discharging the filtered fluid in the housing 20 ,

[0033] The filter element assembly 30 is set in the housing 20 for filtering the fluid entering the oil inlet 11 and discharging the filtered oil from the oil outlet 12,

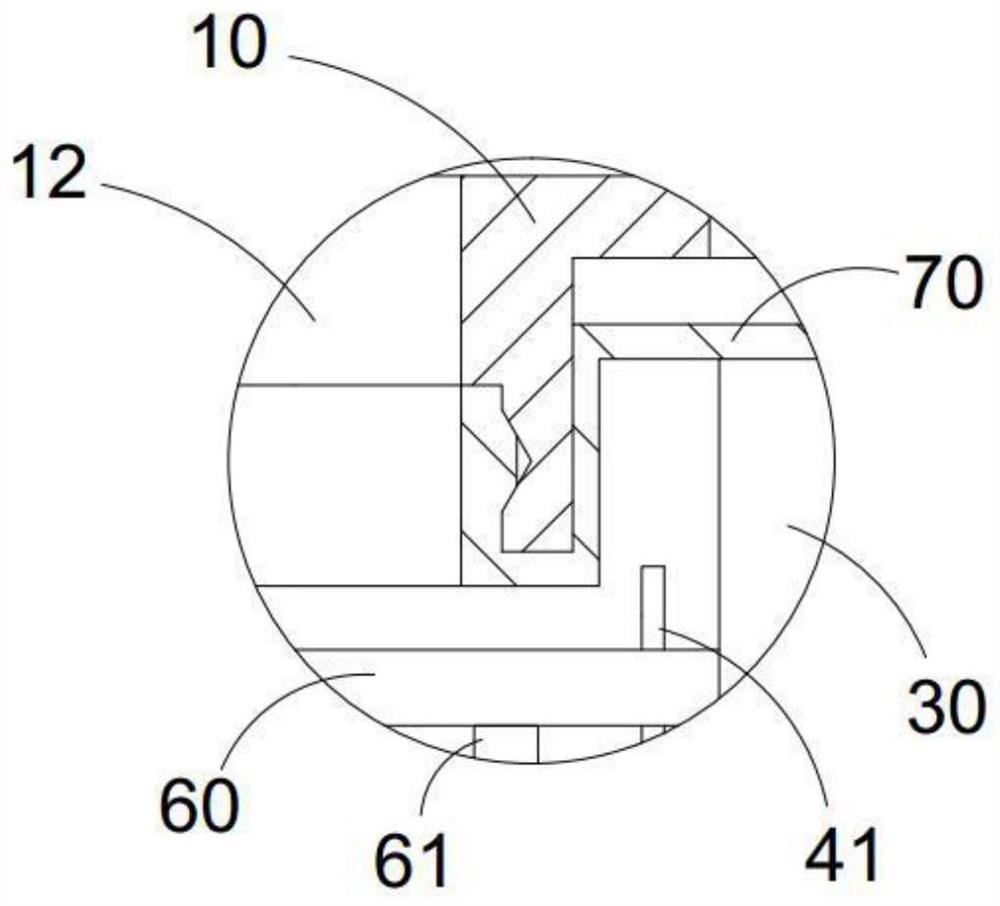

[0034] Wherein, the upper end of the filter element assembly 30 is equipped with a filter element cover plate 70, the filter element cover plate 70 has a second oil inlet pipe 72 for discharging the filtered fluid, and a concave ring is provided between the outer wall of the second oil inlet pipe 72 and the filter element cover plate 70. Assembling the ring groove 71, the threaded cover plate 10 has a first oil inlet pipe 14 that is plugged and fitted with the assembly r...

Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 is that a liquid level sensor is added in the filter element assembly 30 of this embodiment, which is not shown in the figure. The area between the highest level of the area is used to detect whether the oil body inside the filter element assembly 30 reaches the altitude layer. When it reaches the level, the trigger signal controls the air extraction assembly 40 to work and pumps part of the oil body into the oil tank to control the oil inside the filter element assembly 30. The oil outlet 12 is generally connected to a high-pressure oil pump to extract and filter the oil, and the oil inlet 11 is generally connected to an oil delivery pump to input diesel oil.

Embodiment 3

[0048] When the diesel oil filter with oil level control of the present invention actually works: the diesel oil is input into the housing 20 through the oil inlet through the oil transfer pump, the oil body continuously enters and precipitates in the housing 20, and impurities are deposited in the housing At the bottom of the body 20, when the oil body in the housing 20 reaches the level of the filter element assembly 30, the filter element assembly 30 filters the oil body so that it enters the interior of the filter element assembly 30 and is filtered by the secondary filter plate 60. During the above filtering process, the oil body The air present in the air will be separated and gathered on the top surface of the filter element assembly 30, and then discharged by the air extraction assembly 40. At the same time, the liquid level of the oil body in the housing 20 and the filter element assembly 30 can be controlled through the extraction assembly 40. When cleaning the filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com