Hydraulic control system for ditcher

A hydraulic control system and ditching machine technology, which is applied to fluid pressure actuated system components, mechanical equipment, earth movers/shovels, etc., can solve the difficulty of adjusting the depth of the ditch, difficulty in improving construction efficiency, and working conditions Single and other problems, to achieve the effect of adding multiple protection designs, improving construction efficiency, and avoiding equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Shown in the accompanying drawings, the present invention is further described:

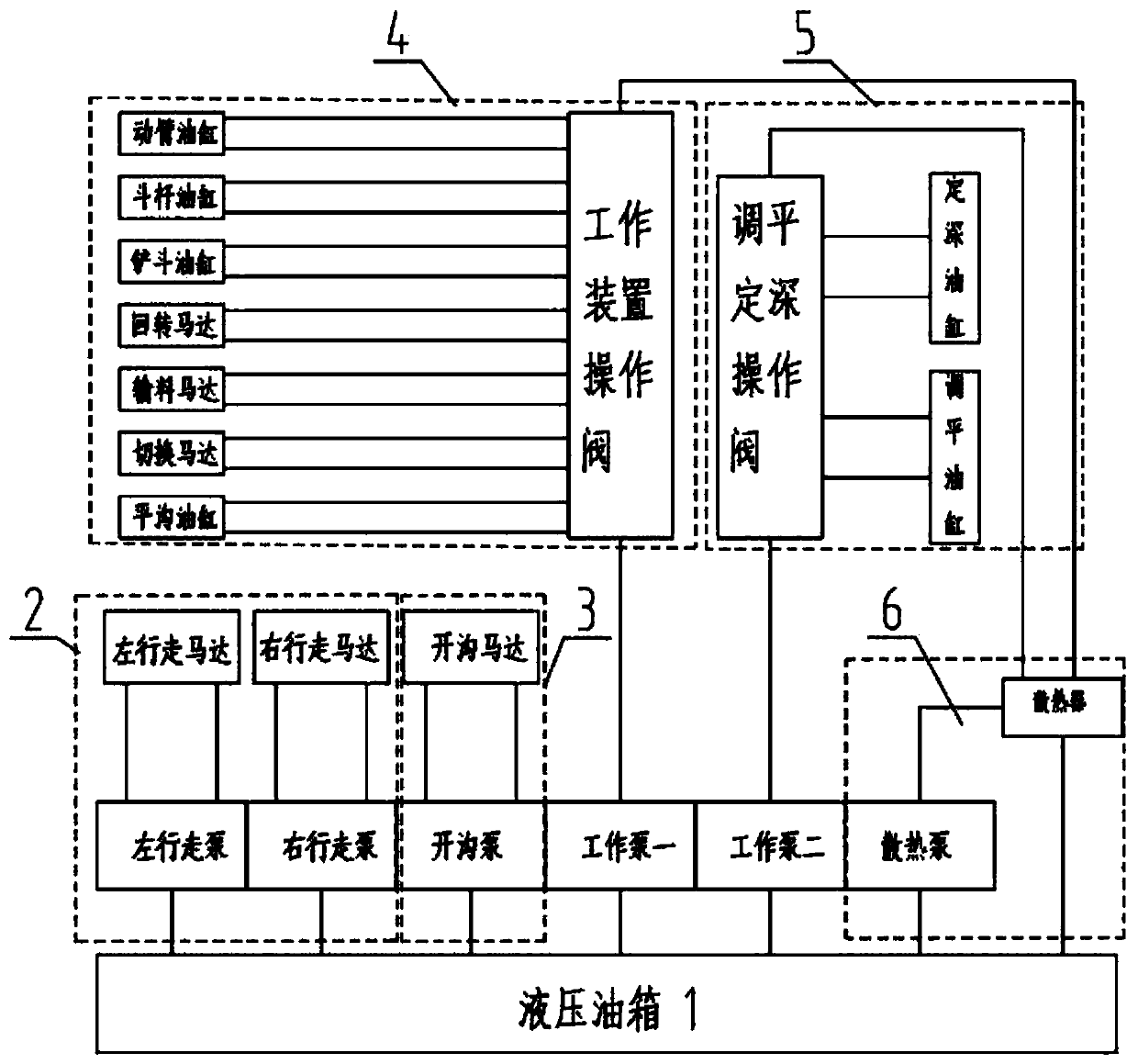

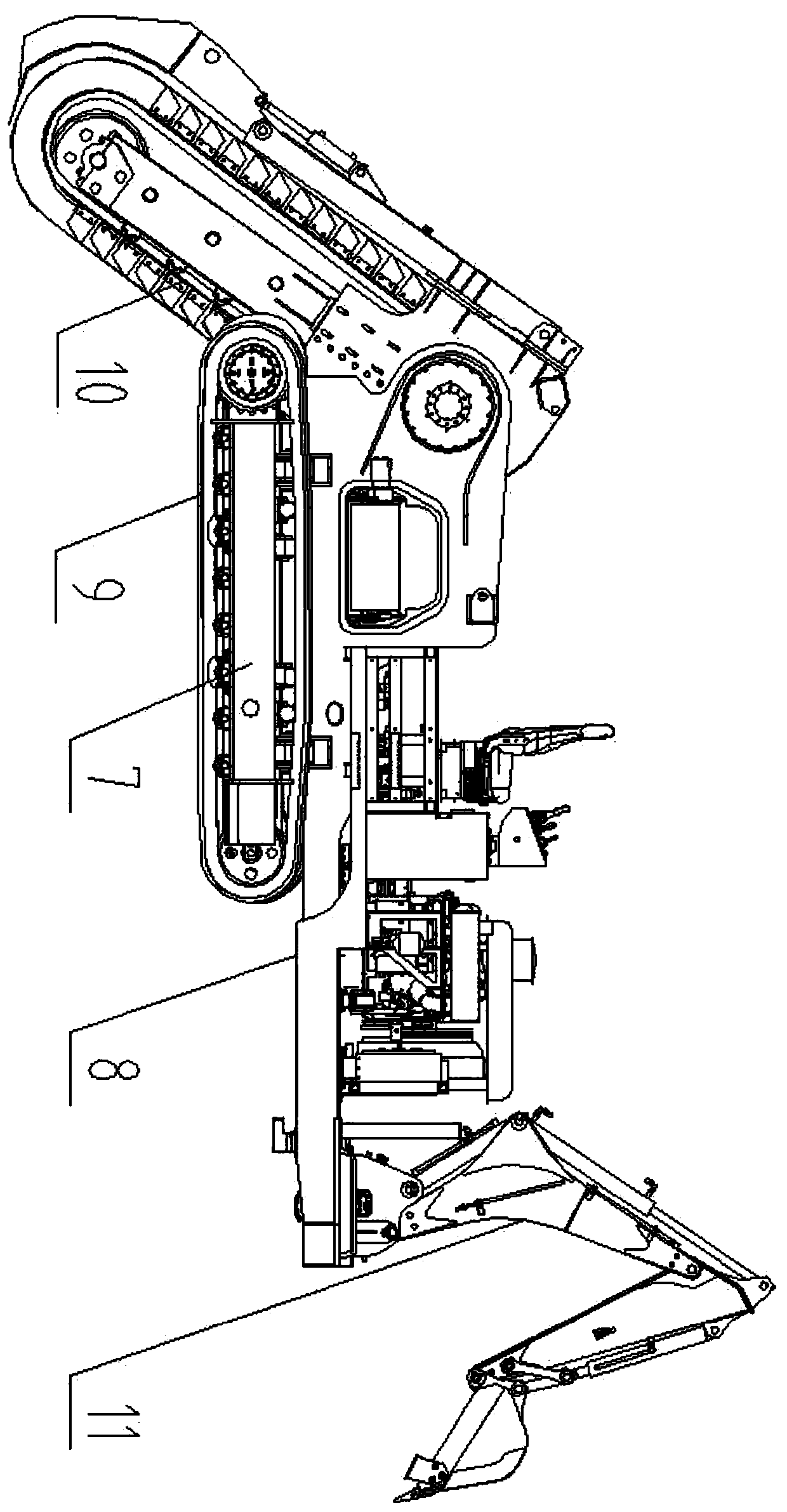

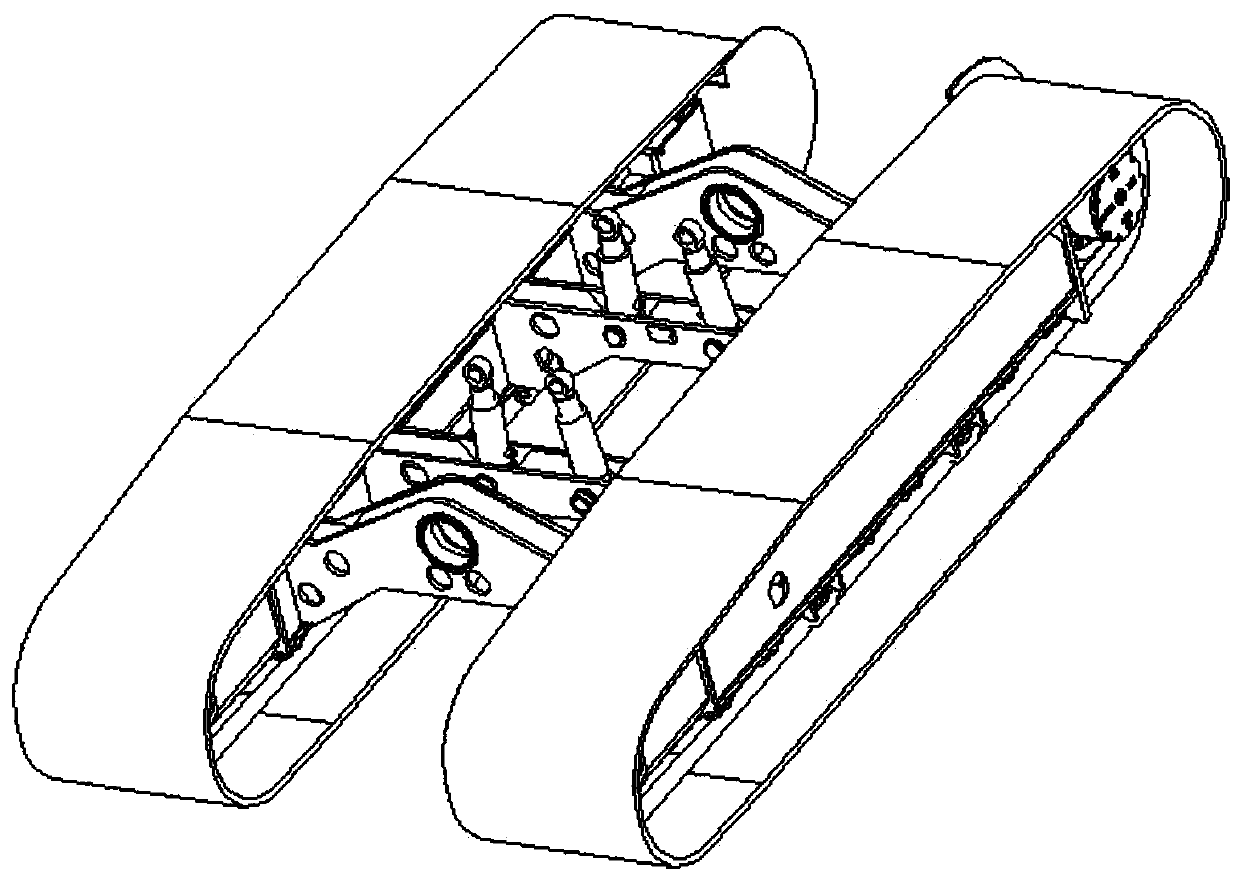

[0031] Such as figure 1 As shown, a hydraulic control system for a ditching machine includes a hydraulic oil tank 1, a traveling unit 2, a ditching unit 3, an excavating unit 4, a ditching adjustment unit 5, and a cooling unit 6. The traveling unit 2 is used for independent driving and is mounted on the chassis 7 The walking crawlers 9 on both sides and the ditching unit 3 are used to drive the ditching device 10 to rotate. The ditching motor 31 is driven, the excavation unit 4 is used to control the work of the excavation device 11, the ditching adjustment unit 5 is used to adjust the angle between the chassis 7 and the frame 8 on the one hand, and is used to adjust the angle of the ditching device 10 on the other hand. Ditching depth, heat dissipation unit 6 is used for heat dissipation of valves, oil pumps and oil cylinders in the hydraulic control system.

[0032] Such as figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com