Wide-working-frequency-band reflective electrical thickness test method

A technology of working frequency band and testing method, which is applied in the field of wide working frequency band reflection electrical thickness testing, can solve the problems that restrict the direct application of reflection method, and the reflection coefficient phase can not reflect IPD monotonously, so as to achieve good measurement linearity and reduce measurement difficulty , The effect of solving engineering application problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0022] A wide working frequency band reflective electrical thickness testing method, comprising the following steps:

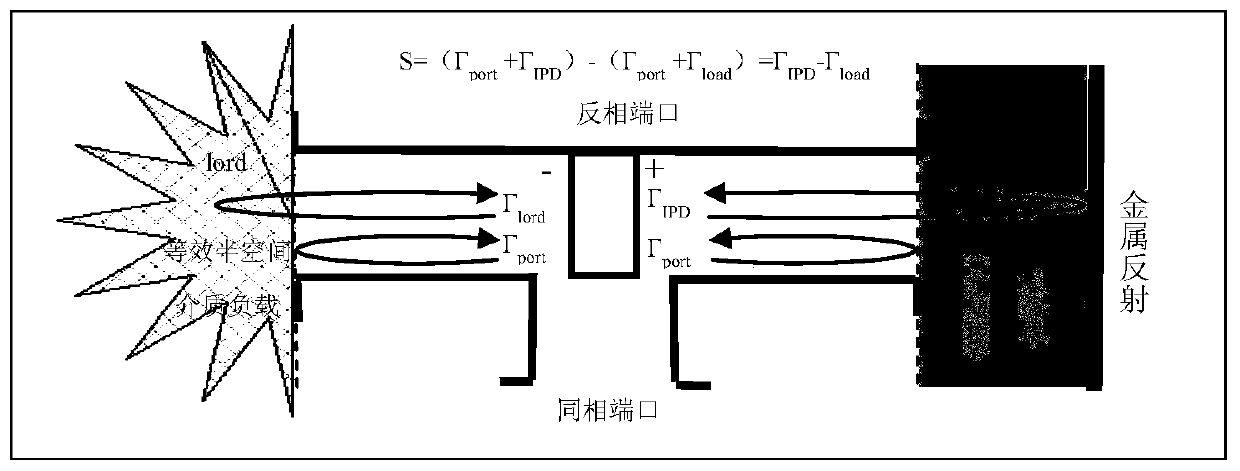

[0023] Step 1: Take the two symmetrical ports of the Magic Wave T as the reflection measurement ports, connect them to the radome under test and the equivalent half-space dielectric load respectively, and use the in-phase port and the anti-phase port of the Magic Wave T as the excitation signal input port and reflection Signal output detection port; such as figure 2 shown;

[0024] Step 2: Utilize the transmission characteristics of the waveguide magic T to isolate the signal pass-through from the input port to the output port, and symmetrically cancel the non-matching reflection component Γ port transmission to the output port;

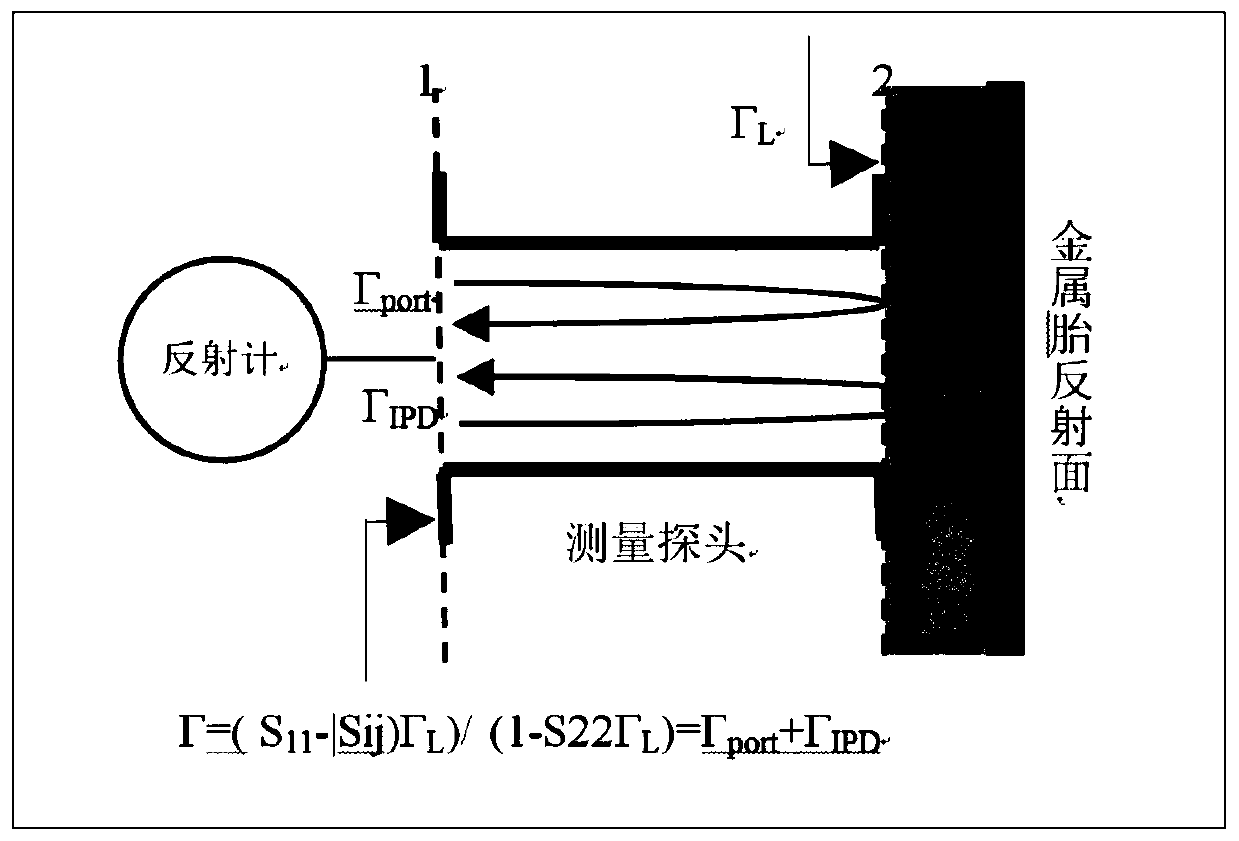

[0025] Step 3: IPD reflection signal Γ of the radome under test IPD Equivalent IPD reflection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com