Active medical device reliability test method based on combined stress

A medical device and comprehensive stress technology, applied in the field of active medical device reliability test based on comprehensive stress, can solve the problems of increasing development costs, prolonging the development cycle of high-quality products, and not being able to fully verify product reliability, and reducing The effect of development cost and shortening development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

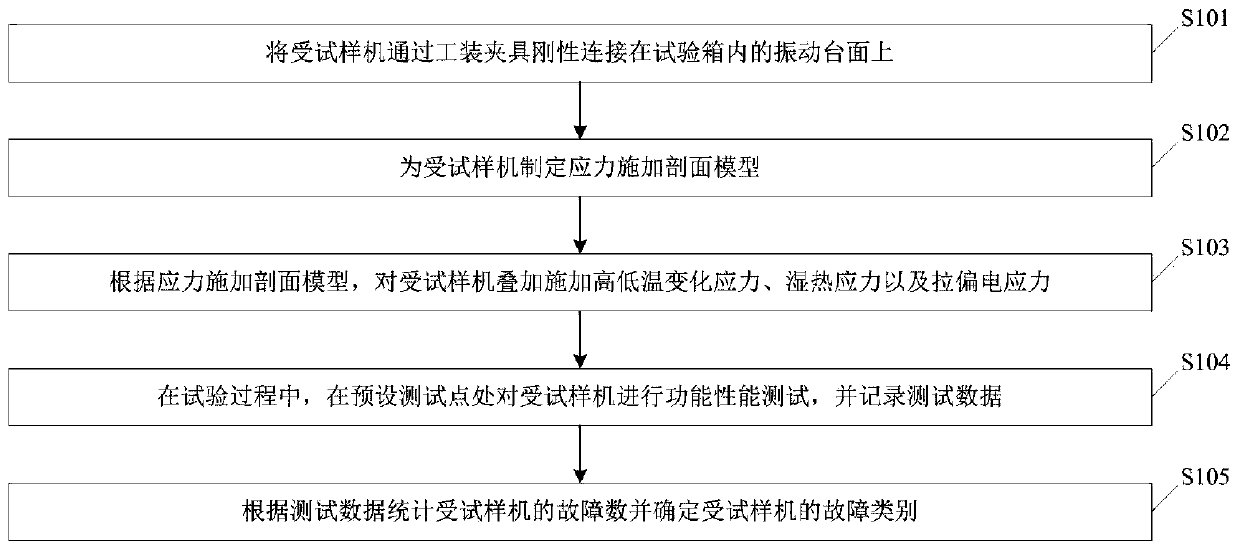

Method used

Image

Examples

Embodiment 1

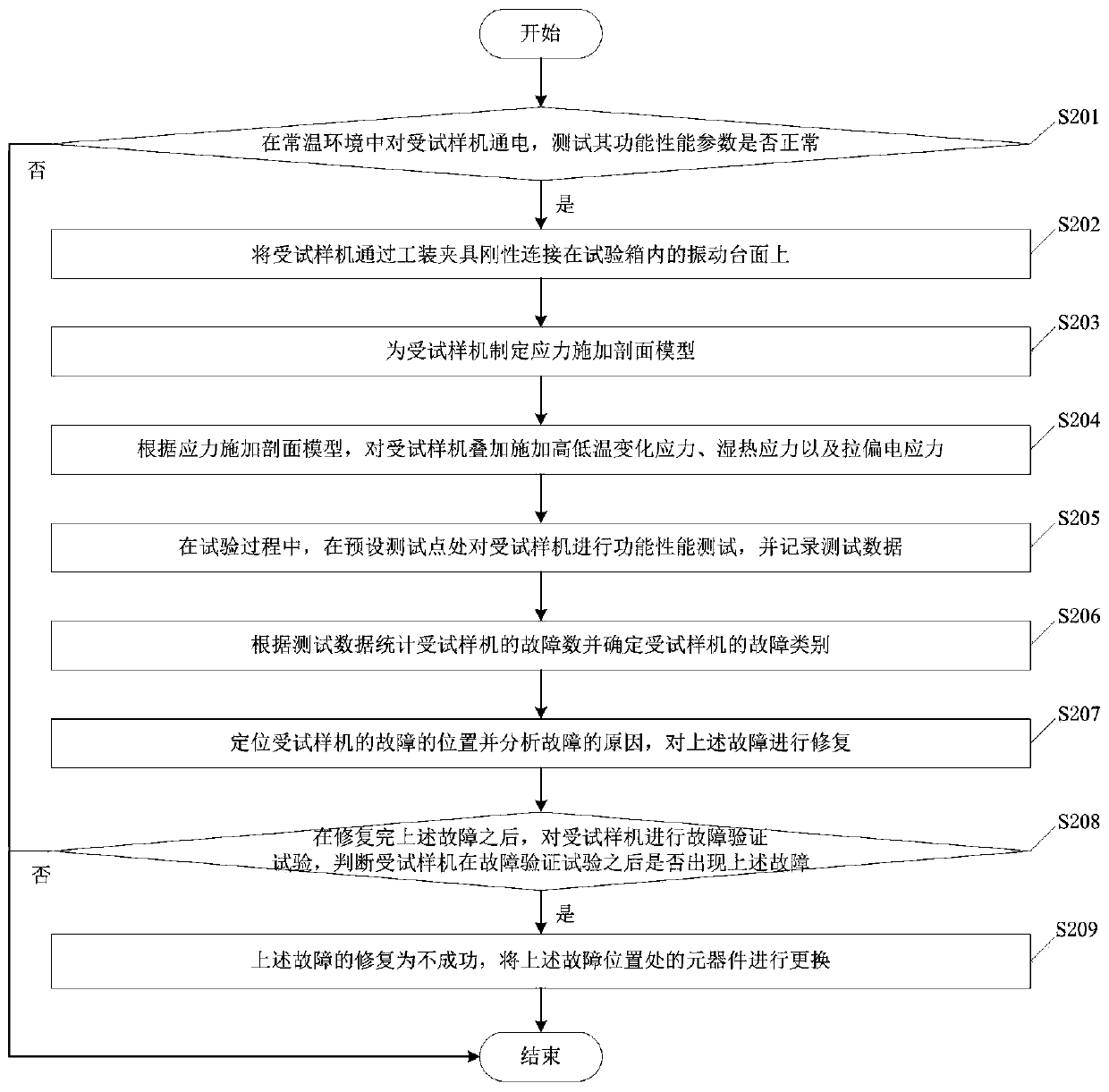

[0042] This embodiment provides another active medical device reliability test method based on comprehensive stress, such as figure 2 as shown, figure 2 It is a flow chart of another comprehensive stress-based active medical device reliability test method according to Embodiment 1 of the present invention, including the following steps:

[0043] Step S201: power on the sample machine in a normal temperature environment, and test whether its functional performance parameters are normal; if yes, execute steps S202 to S208;

[0044] Step S202: Rigidly connect the sample machine to the vibrating table in the test box through the fixture;

[0045] In the embodiment of the present invention, the above-mentioned test box is a rapid temperature change test box, which can adjust the temperature, humidity and vibration stress when the test machine is subjected to the reliability test, so that the test machine can be comprehensively tested under the condition of comprehensive stress. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com