LED display screen module adopting stacking according to blocks for realizing packaging, and packaging method

A technology of LED display screen and LED chip, which is applied in the direction of identification devices, instruments, etc., can solve the problems of large pixel pitch, low display resolution, and insufficient display effect, and achieve high resolution, low labor cost, and high display effect. Better delicate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

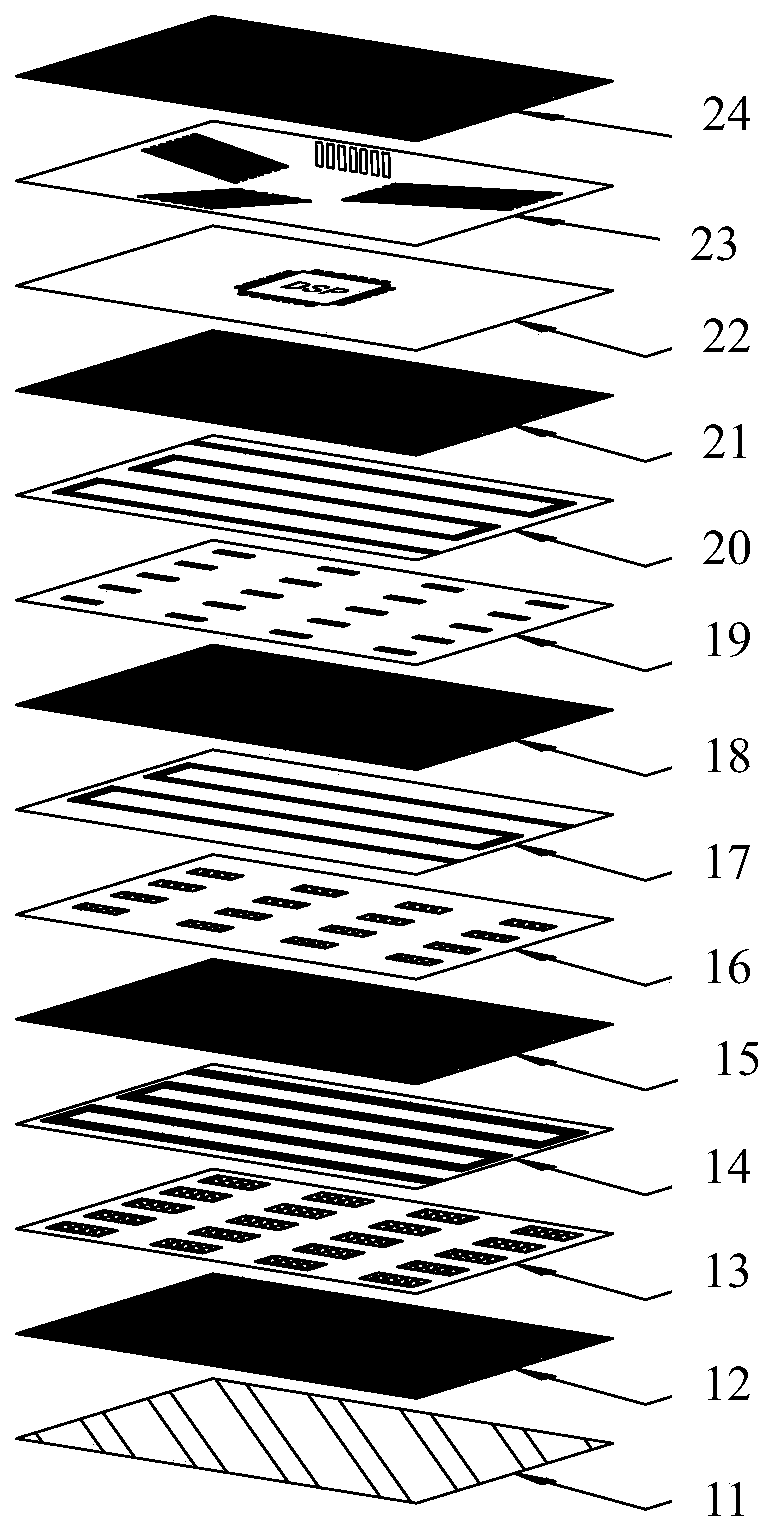

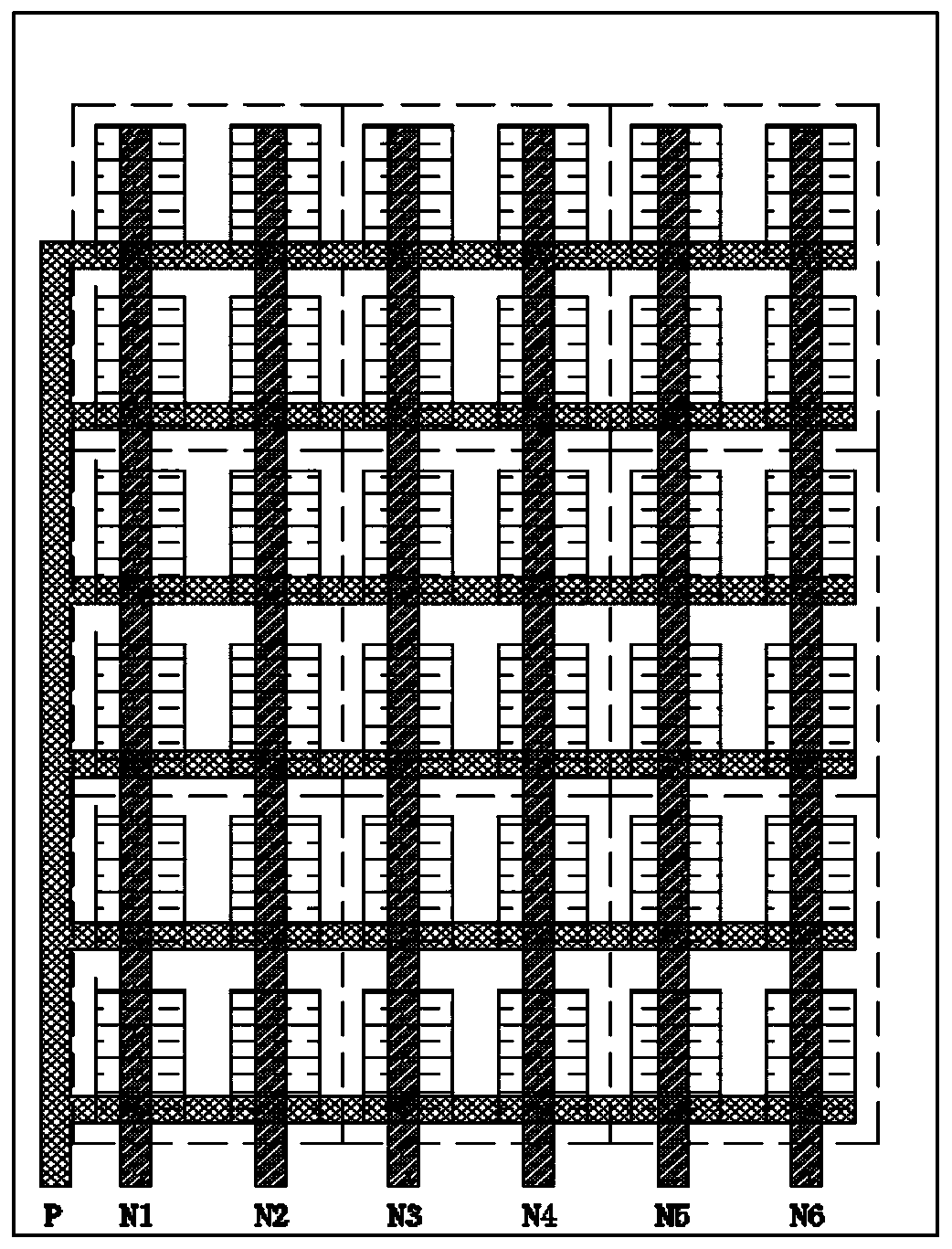

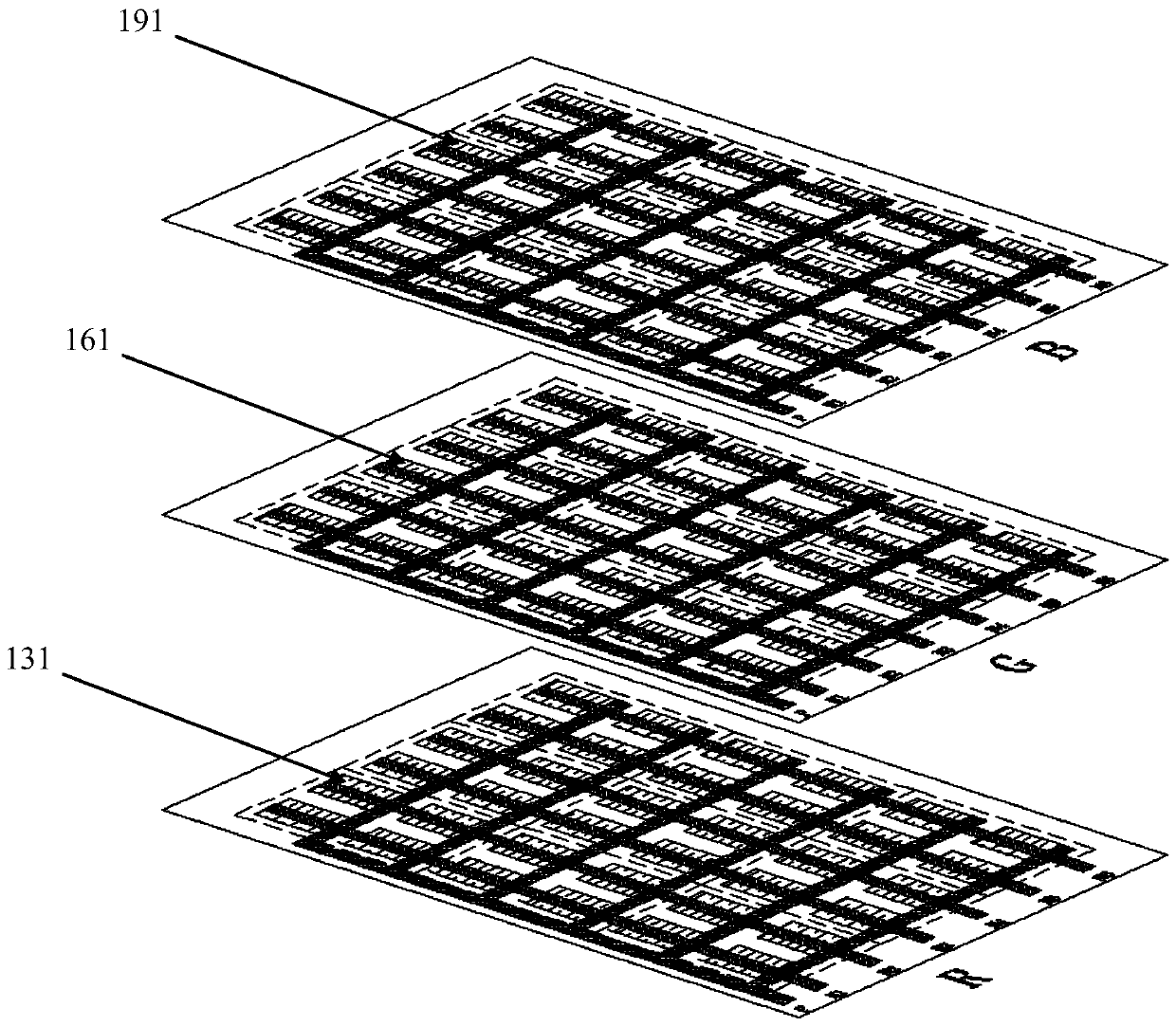

[0026] Such as figure 1 , figure 2 , image 3 As shown, the LED display module of the present invention stacked and packaged by blocks includes a light-transmitting screen substrate 11 on the surface of the display screen, and a red LED layer 13 and a green LED layer 13 are stacked in any order on the light-transmitting screen substrate 11. Layer 16, blue LED layer 19, and LED light emission control device layer 22 located on red LED layer 13, green LED layer 16, and blue LED layer 19. The green LED layer 16 is composed of a green LED chip block 161 which can be transferred as a whole, and the blue LED layer 19 is composed of a blue LED chip block 191 which can be transferred and placed as a whole. The translucent screen The substrate 11, the red LED layer 13, the green LED layer 16, the blue LED layer 19, and the LED lighting control device layer 22 pass through the shadowless adhesive layer 12, the shadowless adhesive layer 15, the shadowless adhesive layer 18, and the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com