Pouch lithium battery anti-thermal-radiation aluminum foil pouch forming die and manufacturing method thereof

A soft-packed lithium battery and aluminum foil bag technology is applied in the manufacture of electrolyte batteries, battery pack components, non-aqueous electrolyte batteries, etc. The effect of easy injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

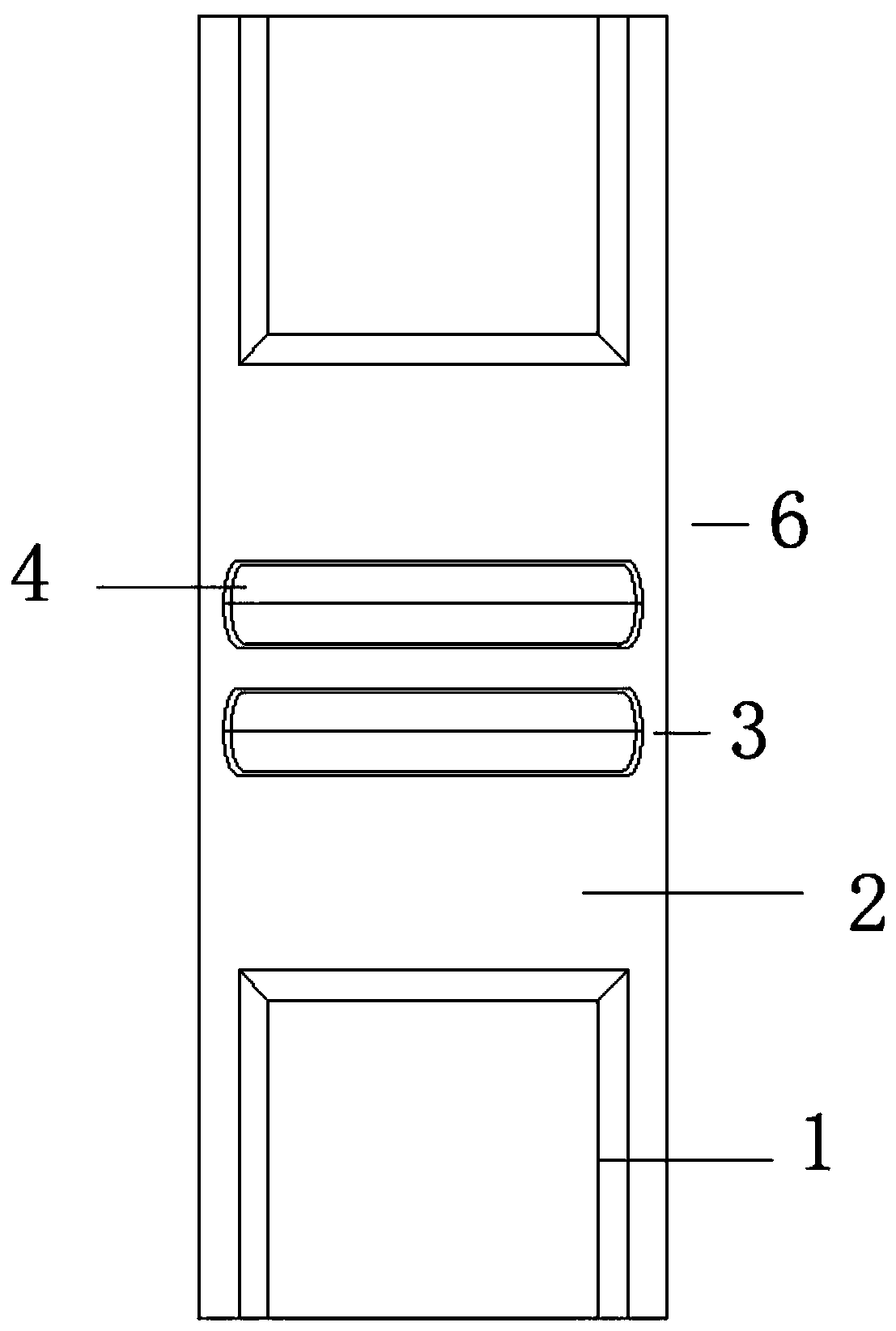

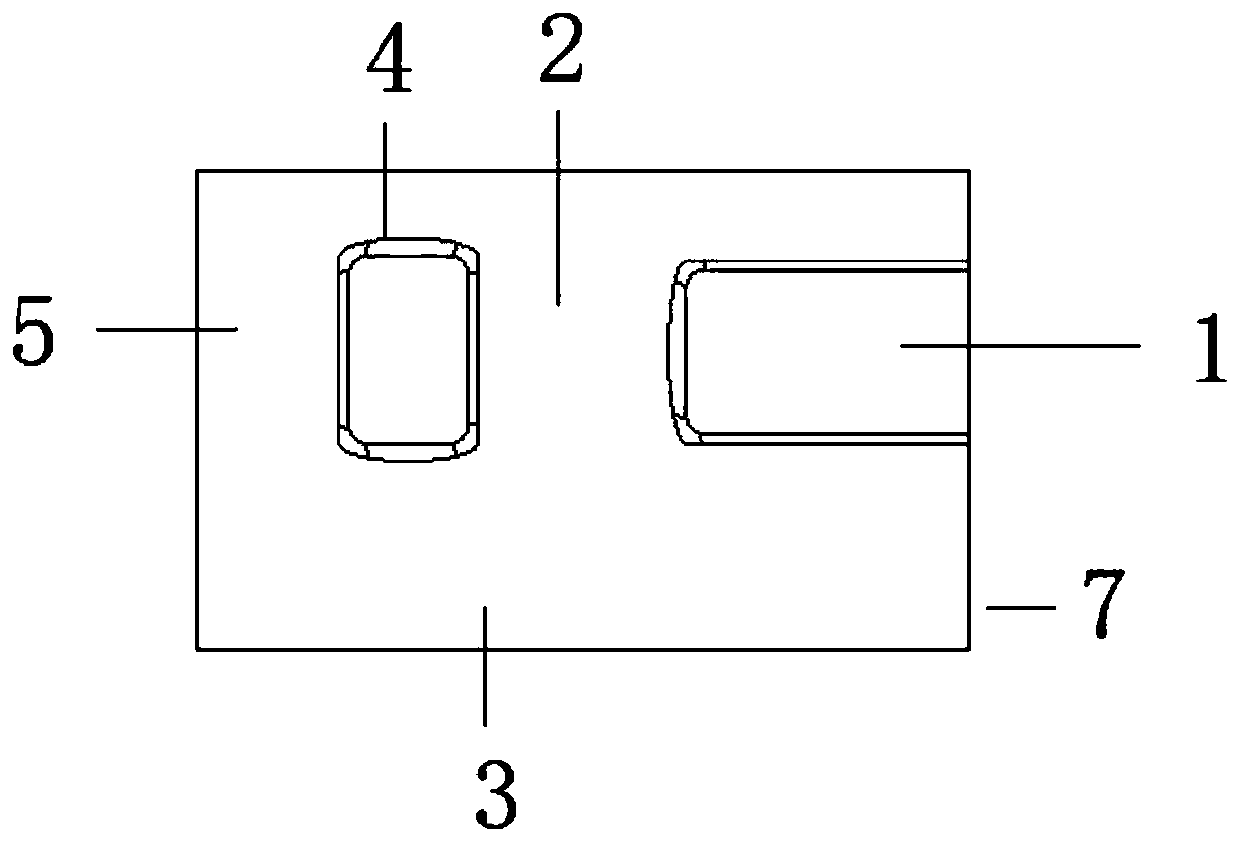

[0021] Such as Figure 1-2 As shown, this specific embodiment adopts the following technical solutions: a heat-radiation-proof aluminum foil pouch forming die for a soft-pack lithium battery, including a cylindrical foil pouch forming die 6 and a square foil pouch forming die 7 .

[0022] Wherein, the cylindrical foil bag molding die 6 is composed of an airbag 1, a second sealing area 2, a top sealing area 3 and a cell placement pit body 4, and the cell placement pit body 4 and the air bag 1 are separated by The two sealing areas 2, the other two sides between the cell placement pit body 4 and the airbag 1 are top sealing areas 3.

[0023] Wherein, the cell placement pit 4 and the airbag 1 are arranged symmetrically with respect to the central axis of the cylindrical foil bag molding die 6 .

[0024] Wherein, the square foil bag forming die 7 is composed of an airbag 1, a second sealing area 2, a top sealing area 3, a cell placement pit body 4 and a side sealing area 5, the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com