Egg yolk processing and stuffing filling process for moon cake production

A technology for egg yolks and moon cakes, which is applied in the field of egg yolk processing and filling technology, can solve the problems of uneasy mass percentage or weight preparation, high hardness and saltiness of moon cake egg yolks, and difficulty in automation of production processes, and achieves improved softness and ease of production automation. , the effect of easy automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

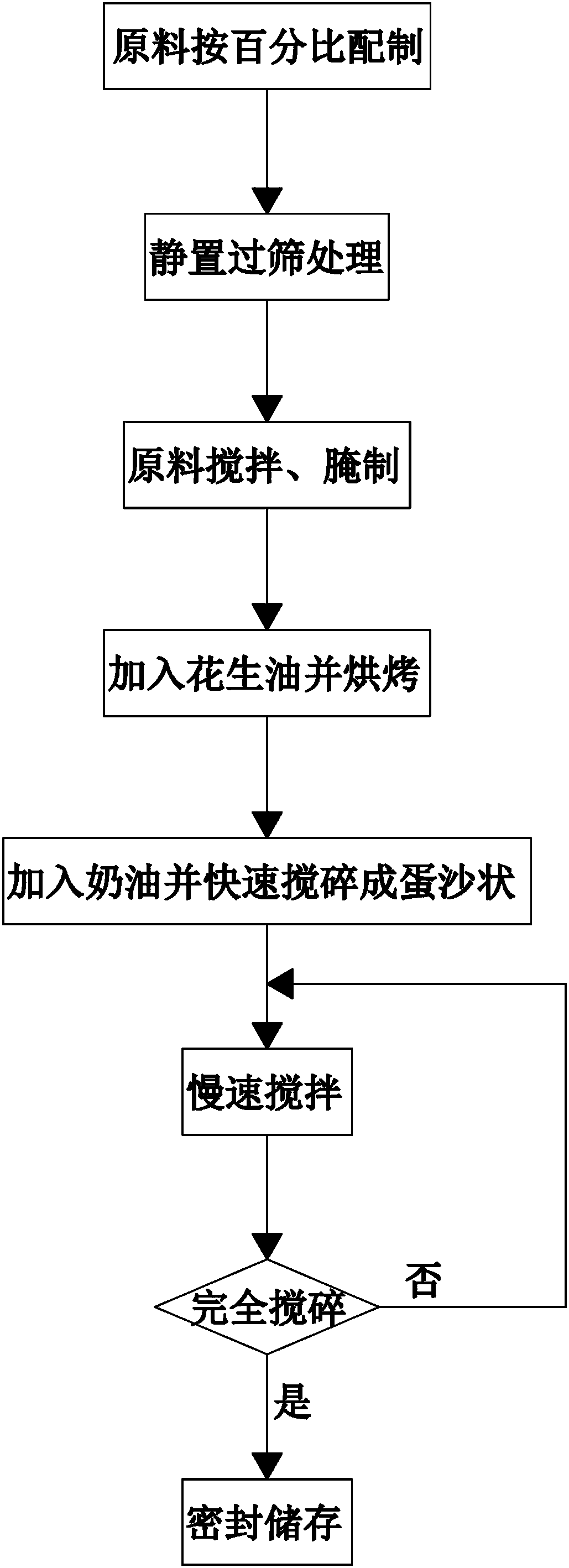

[0021] See attached figure 1 Shown, a kind of egg yolk processing filling technology for moon cake production comprises the following steps:

[0022] S1. Proportion the following raw materials: 75 parts of raw salted egg yolk, 15 parts of Erqu wine or Daqu wine, 5 parts of Tianjin rose wine, 1 part of table salt, respectively screen and remove the raw salted egg yolk, Erqu wine or Daqu wine Impurities; the effect of choosing Daqu wine with an angle of more than 50° is better;

[0023] S2. Stir the raw materials treated in step S1 evenly until they are in a paste state, subject to the absence of particles, then let stand for 1 hour, and then marinate the stirred egg yolks;

[0024] S3. Stir the marinated egg yolk in step S2 and put it on the baking tray, then add 0.5 parts of peanut oil and control the peanut oil to be equal to the egg yolk surface, then put the egg yolk in a flat oven and bake for 15 minutes, and then bake The upper fire temperature is 160 degrees Celsius, a...

Embodiment 2

[0032] See attached figure 1 Shown, a kind of egg yolk processing filling technology for moon cake production comprises the following steps:

[0033] S1. Proportion the following raw materials: 85 parts of raw salted egg yolk, 23 parts of Erqu wine or Daqu wine, 8 parts of Tianjin rose wine, 2 parts of table salt, respectively screen and remove the raw salted egg yolk, Erqu wine or Daqu wine Impurities; the effect of choosing Daqu wine with an angle of more than 50° is better;

[0034] S2. Stir the processed raw materials in step S1 evenly until they are in a paste state, subject to the absence of particles, and then let stand for 2 hours, and then marinate the stirred egg yolks;

[0035] S3. Stir the marinated egg yolk in step S2 and put it on the baking tray, then add 1 portion of peanut oil and control the peanut oil to be even with the egg yolk surface, then put the egg yolk in a flat oven and bake for 30 minutes, and bake The upper fire temperature is 180 degrees Celsiu...

Embodiment 3

[0043] See attached figure 1 Shown, a kind of egg yolk processing filling technology for moon cake production comprises the following steps:

[0044] S1. Proportion the raw materials for the following optimal servings: 80 parts of raw salted egg yolk, 19 parts of Erqu wine or Daqu wine, 6 parts of Tianjin rose wine, and 1 part of table salt, respectively screen raw salted egg yolk, Erqu wine or Daqu wine Treatment to remove impurities; the effect of choosing Daqu wine with an angle of 50° or more is better;

[0045] S2. Stir the raw materials treated in step S1 evenly until they are in a paste state, subject to the absence of particles, then let stand for 1 hour, and then marinate the stirred egg yolks;

[0046] S3. Stir the marinated egg yolk in step S2 and put it on the baking tray, then add 1 portion of peanut oil and control the peanut oil to be equal to the egg yolk surface, then put the egg yolk in a flat oven and bake for 25 minutes, and then bake The upper fire tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com