Marinated meat product and processing technology thereof

A processing technology and product technology, which is applied in the field of stewed meat products and its processing technology, can solve the problems that the taste of cold soaking soup is difficult to fully penetrate, the thermal movement of molecules is not violent enough, and the effect is not obvious enough, so as to achieve short processing time and food safety High performance, effective in solving technical problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The processing technology of a kind of stewed meat product designed in the present embodiment comprises the following steps:

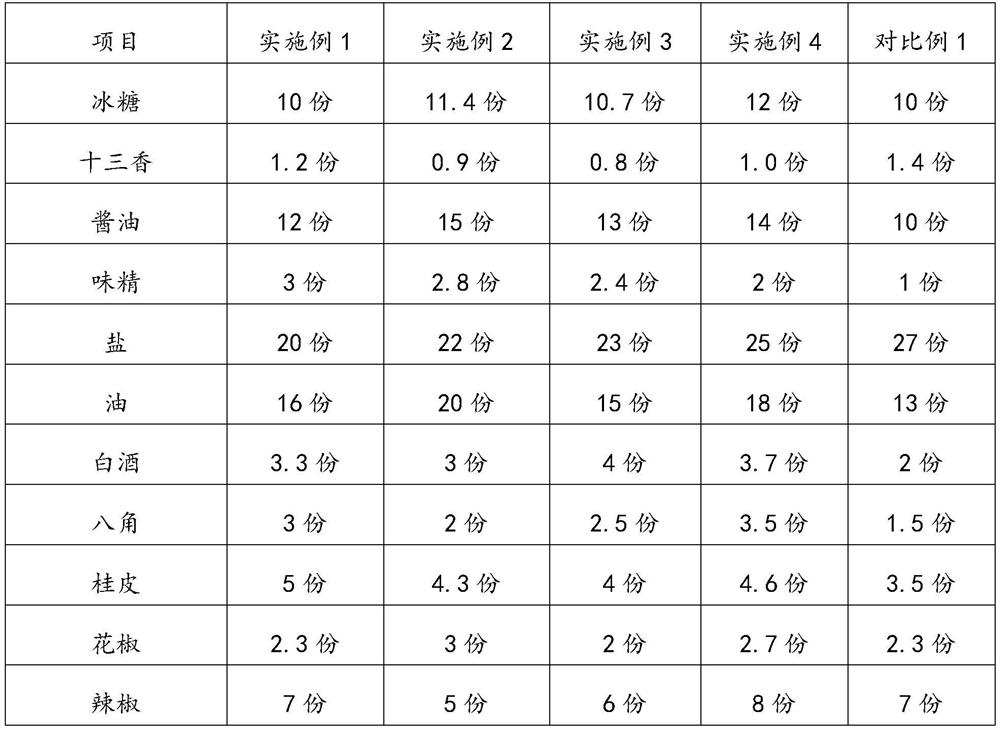

[0038] 1) In terms of mass parts, 10 parts of rock sugar, 1.2 parts of thirteen incense, 12 parts of soy sauce, 3 parts of monosodium glutamate, 20 parts of salt, 16 parts of oil, 3.3 parts of white wine, 3 parts of star anise, 5 parts of cinnamon, 2.3 parts of peppercorns, Boil 7 parts of pepper and 1000 parts of water to make brine;

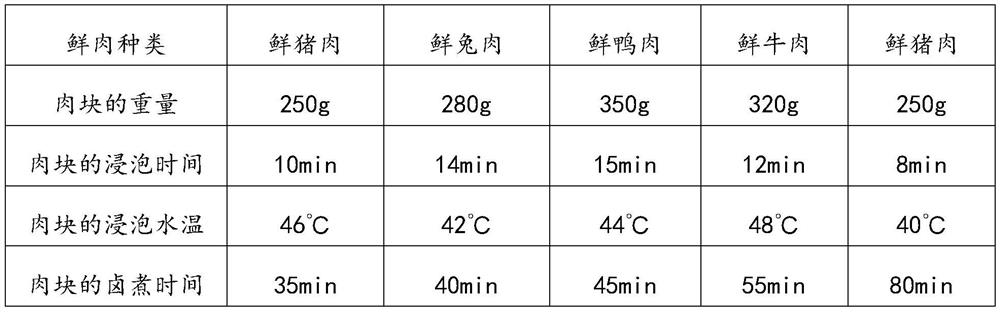

[0039] 2) Cut the fresh pork into block-shaped meat pieces with a weight of 250g, prick a number of holes on the meat pieces, soak them in water at a temperature of 46°C for 10 minutes, blanch and drain;

[0040] 3) After heating the brine in step 1) to 100° C., put the meat pieces in step 2) into brine and boil for 35 minutes, and then remove to obtain stewed meat products.

[0041] In step 1), oil is onion ginger oil. The preparation method of the scallion and ginger oil is as follows: put 1 part of diced gre...

Embodiment 2

[0043] The processing technology of a kind of stewed meat product designed in the present embodiment comprises the following steps:

[0044] 1) 11.4 parts of rock sugar, 0.9 parts of thirteen incense, 15 parts of soy sauce, 2.8 parts of monosodium glutamate, 22 parts of salt, 20 parts of oil, 3 parts of white wine, 2 parts of star anise, 4.3 parts of cinnamon, 3 parts of peppercorns, Boil 5 parts of pepper and 1000 parts of water to make brine;

[0045] 2) Cut the fresh rabbit meat into block-shaped meat pieces with a weight of 280g, pierce a plurality of holes on the meat piece, soak in water at a temperature of 42°C for 14min, blanch and drain;

[0046] 3) After heating the brine in step 1) to 100° C., put the meat pieces in step 2) into brine and boil for 40 minutes, and then remove to obtain stewed meat products.

[0047] In step 1), oil is onion ginger oil. The preparation method of the scallion and ginger oil is as follows: put 1 part of diced green onion and 0.8 part ...

Embodiment 3

[0049] The processing technology of a kind of stewed meat product designed in the present embodiment comprises the following steps:

[0050] 1) 10.7 parts of rock sugar, 0.8 parts of thirteen incense, 13 parts of soy sauce, 2.4 parts of monosodium glutamate, 23 parts of salt, 15 parts of oil, 4 parts of white wine, 2.5 parts of star anise, 4 parts of cinnamon, 2 parts of peppercorns, Boil 6 parts of pepper and 1000 parts of water to make brine;

[0051] 2) Cut the fresh duck meat into block-shaped meat pieces with a weight of 350g, pierce a plurality of holes on the meat pieces, soak them in water at a temperature of 44°C for 15min, blanch and drain;

[0052] 3) After heating the brine in step 1) to 100° C., put the meat pieces in step 2) into brine and boil for 45 minutes, then remove and obtain stewed meat products.

[0053] In step 1), oil is onion ginger oil. The preparation method of the scallion and ginger oil is as follows: put 1 part of diced green onion and 0.8 part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com