Peanut shelling equipment

A technology for peanut shells and peanuts, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of scattered peanut shells and time-consuming manual peanut shell removal, and achieve the effect of preventing flying around and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

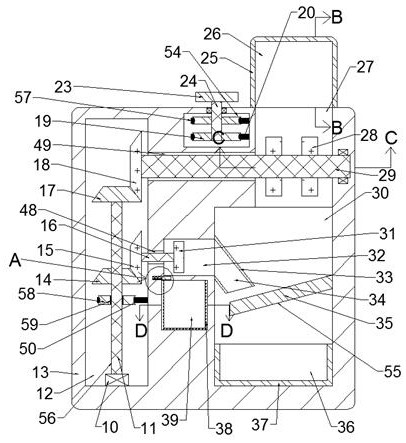

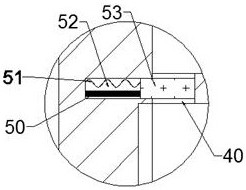

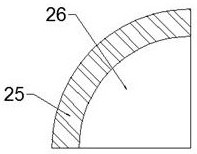

[0023] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0024] A schematic diagram of the mechanical mechanism of a peanut shelling equipment described in conjunction with accompanying drawings 1-5, including a sheller 13, a working chamber 30 and a rotating chamber 12 are provided in the shelling machine 13, and a working chamber 30 is provided with There is a collecting mechanism 55, the collecting mechanism 55 includes a loading plate 35 fixed on the right end wall of the working chamber 30, the left end wall of the working chamber 30 is fixedly provided with a suction pipe 33, and the suction pipe 33 is provided with a suction pipe 34, the suction pipe 33 can suck away the peanut shells;

[0025] The left side of the collection mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com