Milling machine for wooden crafts

A handicraft and wood technology, applied in the field of milling machines for wood handicrafts, can solve problems such as injury to workers, affecting normal processing, and deteriorating working environment, and achieve the effects of improving safe operation, reducing accident rates, and protecting one's own safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

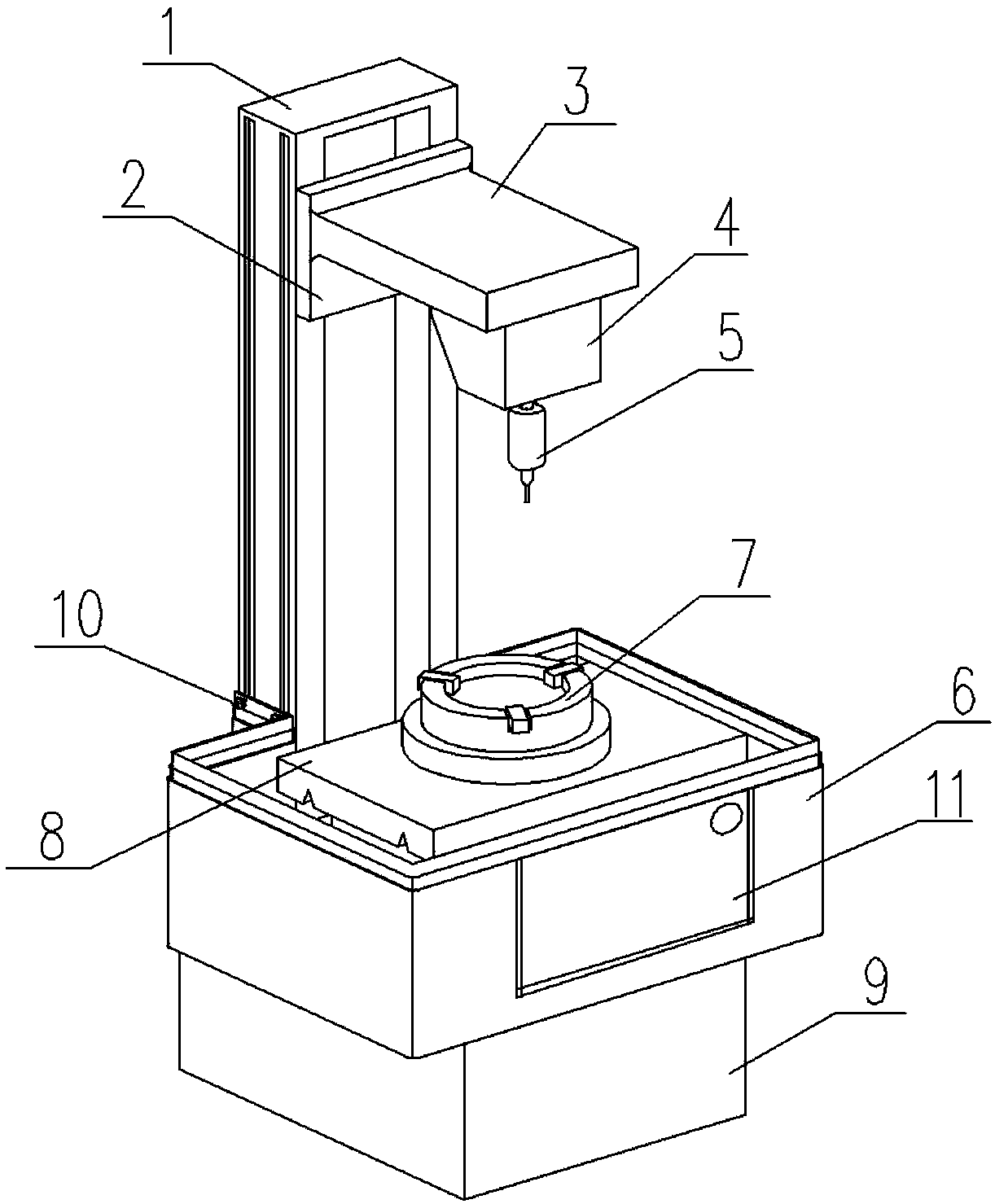

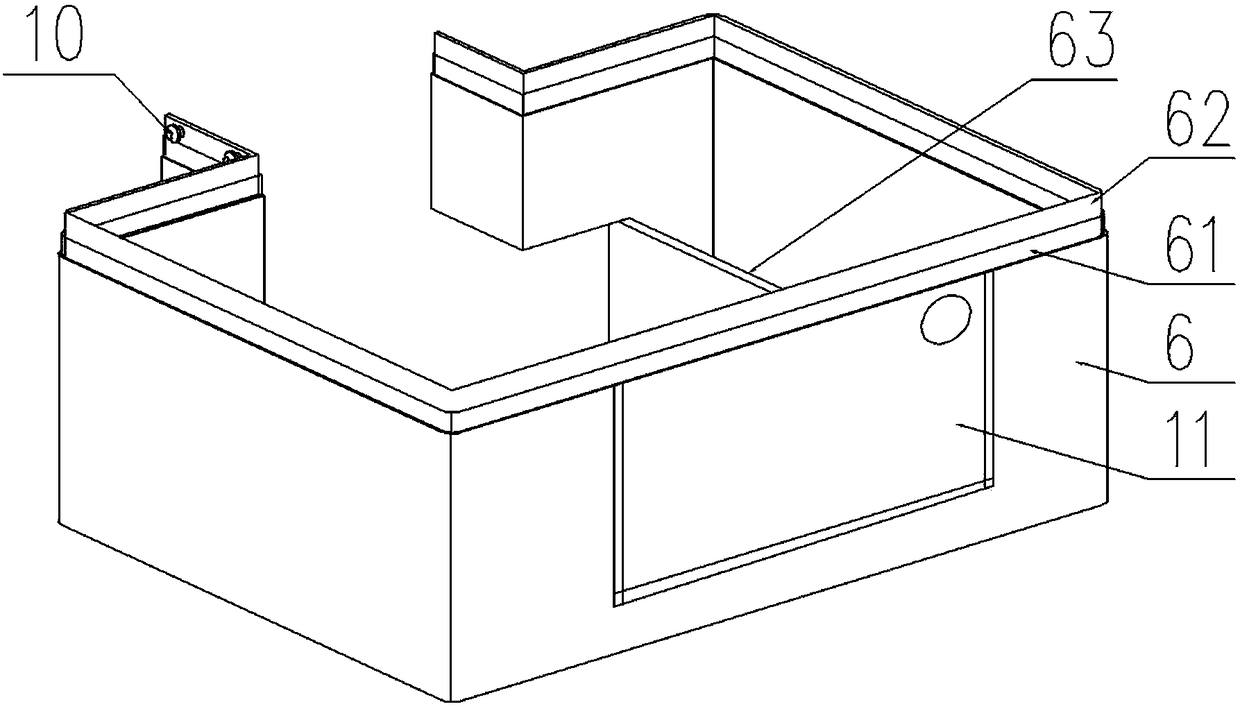

[0021] as attached figure 1 To attach image 3 shown

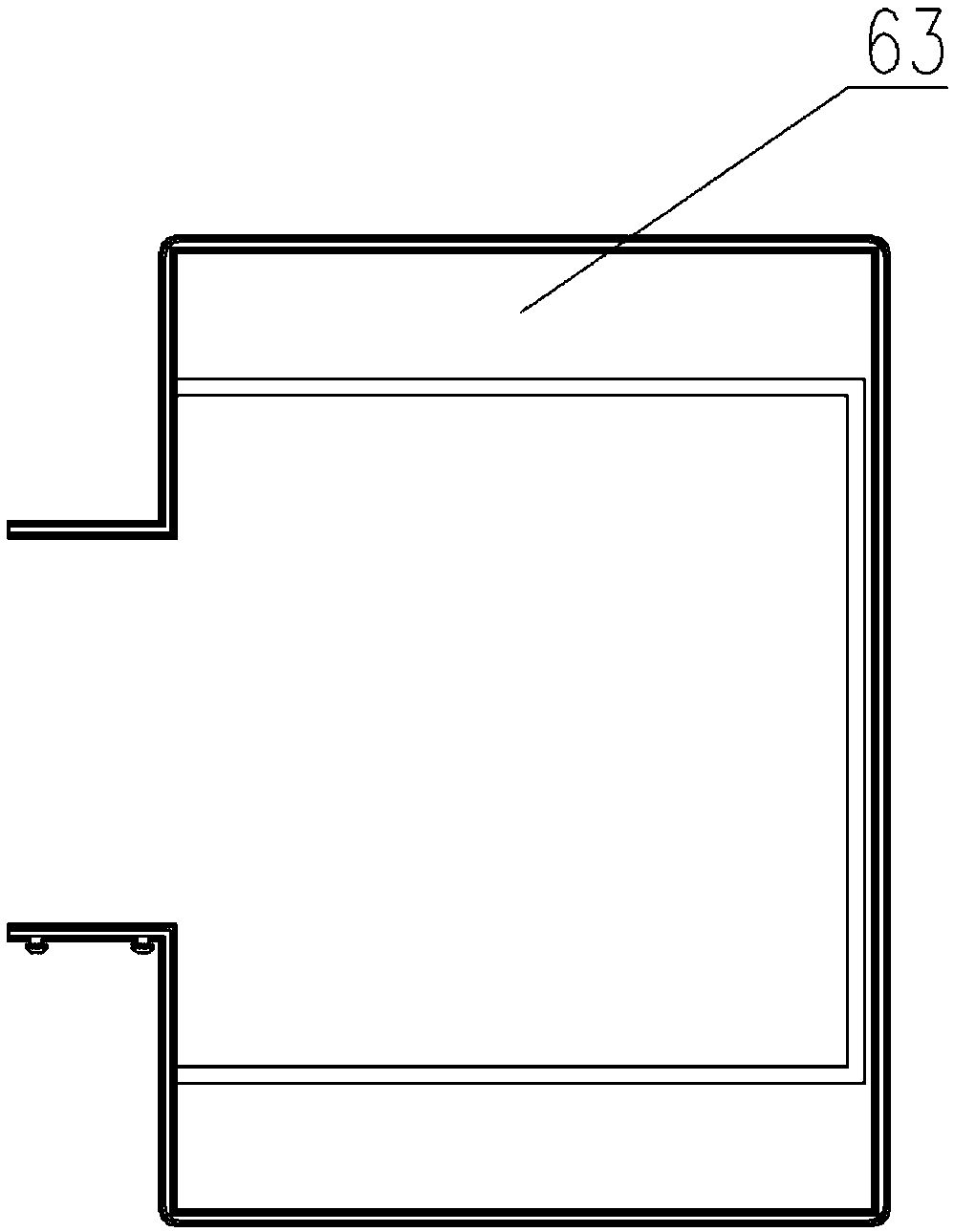

[0022] The invention provides a milling machine for wooden handicrafts, comprising a support arm 1, a slider 2, an installation platform 3, an installation table 4, a spindle head 5, a protective cover 6, a chuck 7, a workbench 8, a base 9, a lifting rod 10 and Operation window 11, the slider 2 is installed on the support arm 1; the lifting rod 10 is installed under the support arm 1; the slider 2 is connected to the installation platform 3; the installation platform 3 is installed under the The mounting table 4; and the spindle head 5 is installed on the mounting table 4; the workbench 8 is installed below the spindle head 5; and the chuck 7 is fixed on the workbench 8; the protective cover is installed on the side of the chuck 7 6; the protective cover 6 includes a protective cover 61, a protective cover 62 and a sawdust bin 63; the protective cover 61 is located inside the protective cover 6; the protective cover 2 62...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com