A kind of airless tire and its production process

A technology of airless tires and tires, which is applied in the direction of non-pneumatic tires, tire parts, tires, etc., can solve the problems of grid-like spoke bearing force influence, impact on tire service life, tire cushioning force and other problems, and achieve processing steps The effect of reasonable design, high replacement cost and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

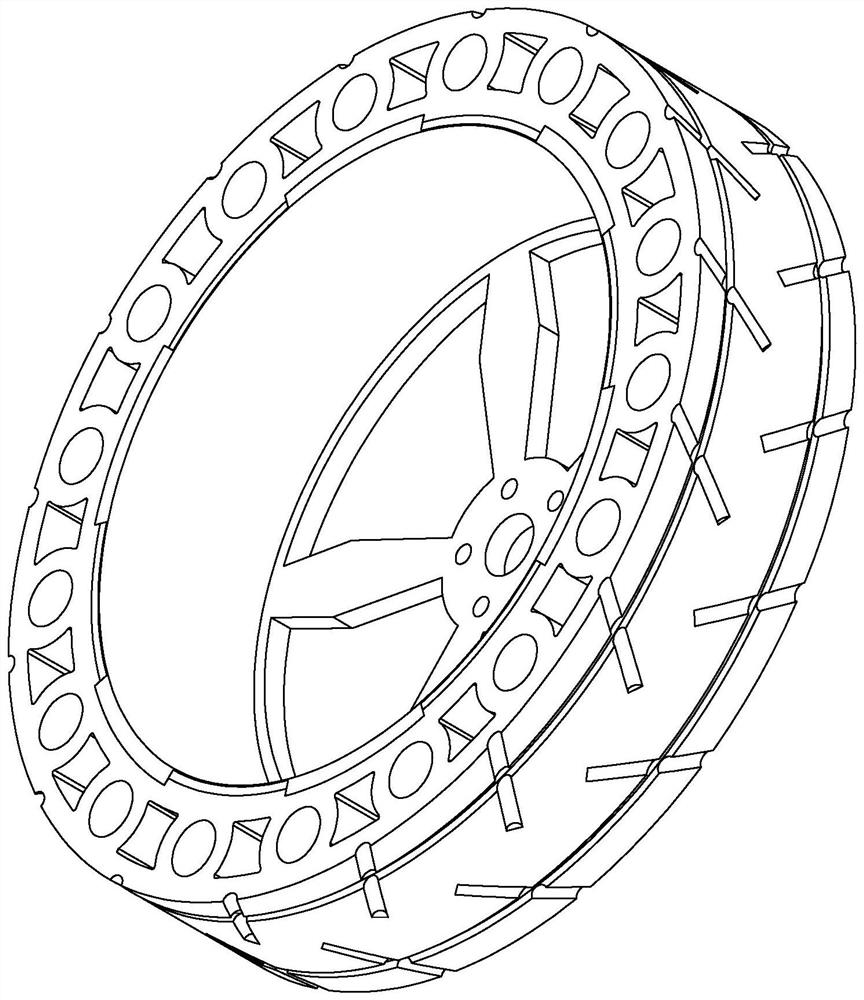

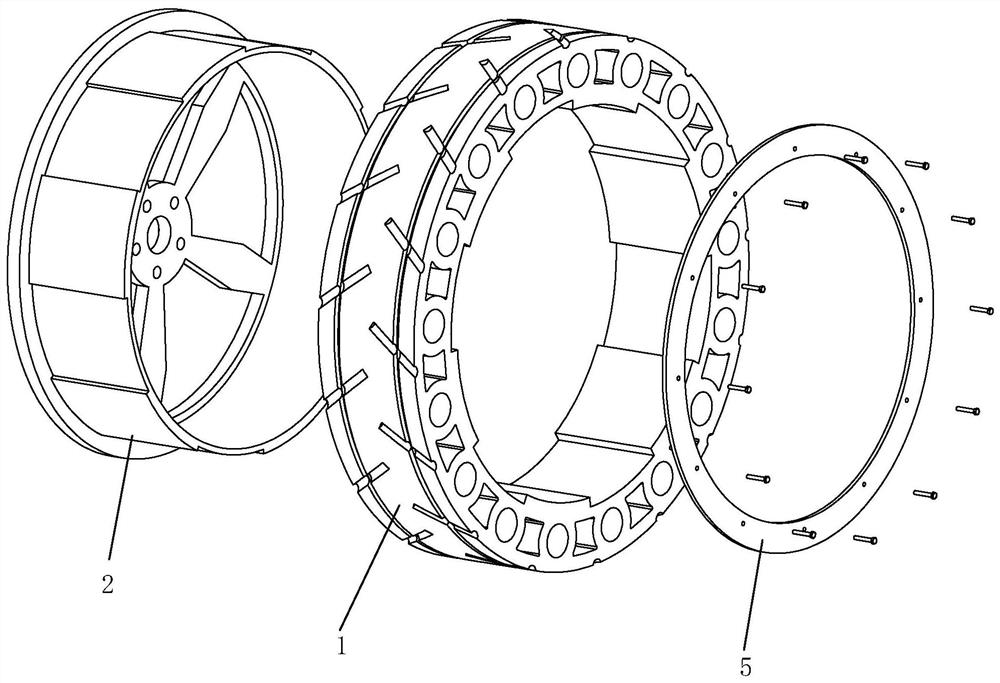

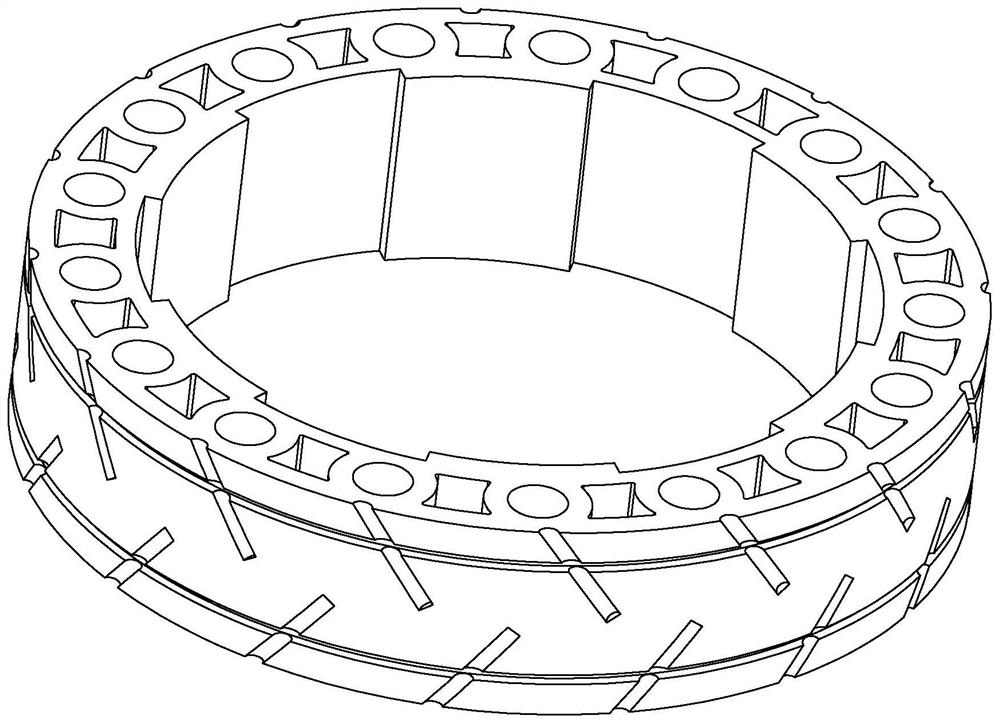

[0044] see Figure 1 to Figure 8 .

[0045]This embodiment is an airless tire, including a hub 2, an inner support member and a tire body 1 integrally formed by casting. When the tire main body 1 is poured, the inner support is poured into the tire main body 1; the tire main body 1 is molded by polyurethane material, and the tire main body 1 is assembled on the wheel hub 2. Orientation in the circumferential direction.

[0046] In this embodiment, high-strength mesh cord fabric 6 and an auxiliary support ring made of perforated steel belts are selected as the inner support. There are two auxiliary support rings, a large auxiliary support ring 4 and a small auxiliary support ring 3, the part of the tire body 1 between the large auxiliary support ring 4 and the small auxiliary support ring 3 is an incomplete solid structure, and the incomplete solid The design of the structure can increase the cushioning performance of the tire. refer to Figure 4 and Figure 8 , which are...

Embodiment 2

[0063] see Figure 9 , the design principle of the tire body is the same as that of the tire body in Example 1, the difference is that the inner support member is made of high-strength mesh cord fabric and an auxiliary support ring a, which is suitable for small ordinary passenger cars.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com