Improved material silo structure based on mining transporting vehicle

A technology of transport vehicles and silos, applied in the field of transport vehicles, can solve problems such as injuries to the waist of workers, increase the burden on enterprises, and affect mineral transportation, etc., and achieve the effects of reducing labor intensity, improving transportation speed, and avoiding injuries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

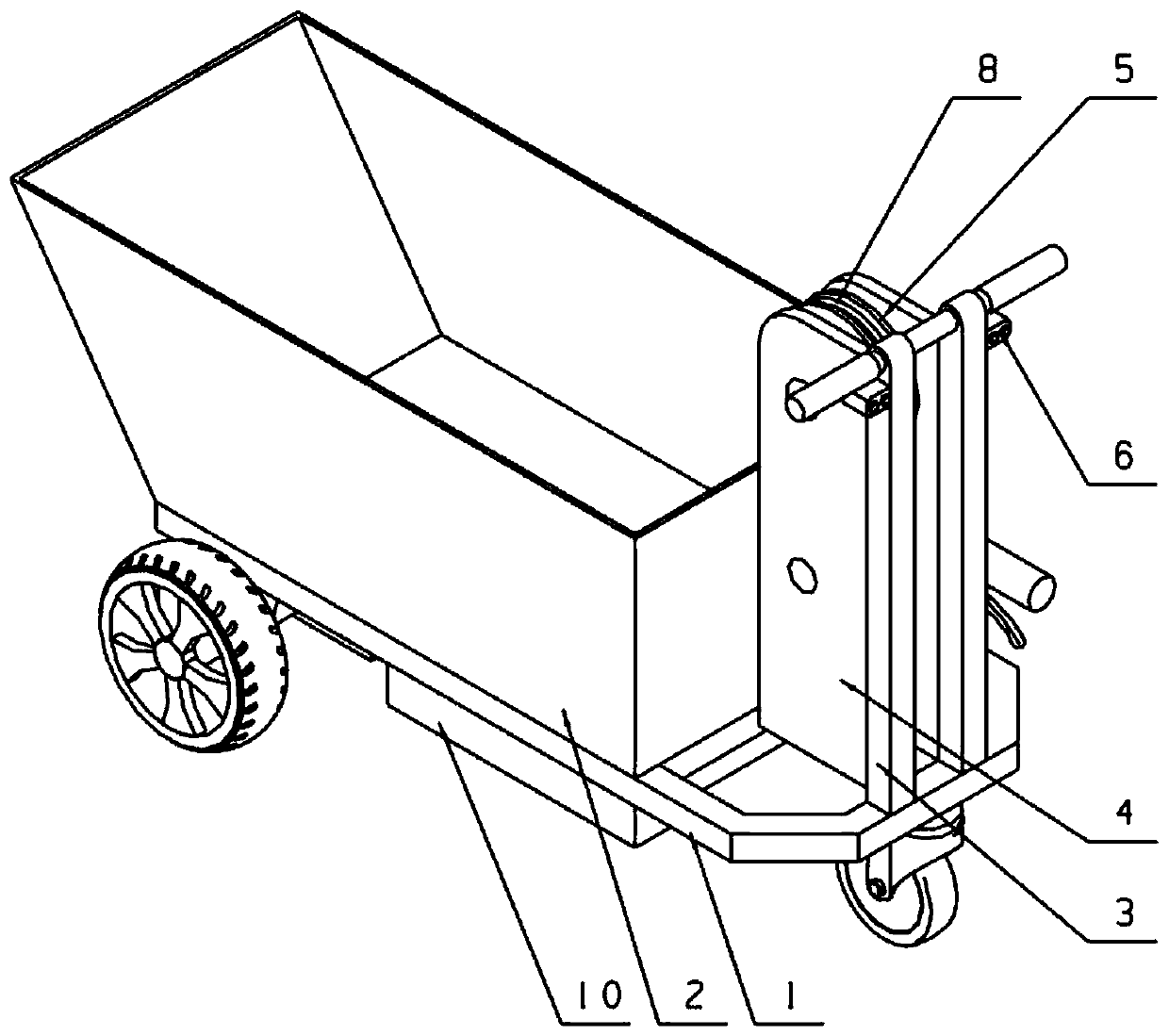

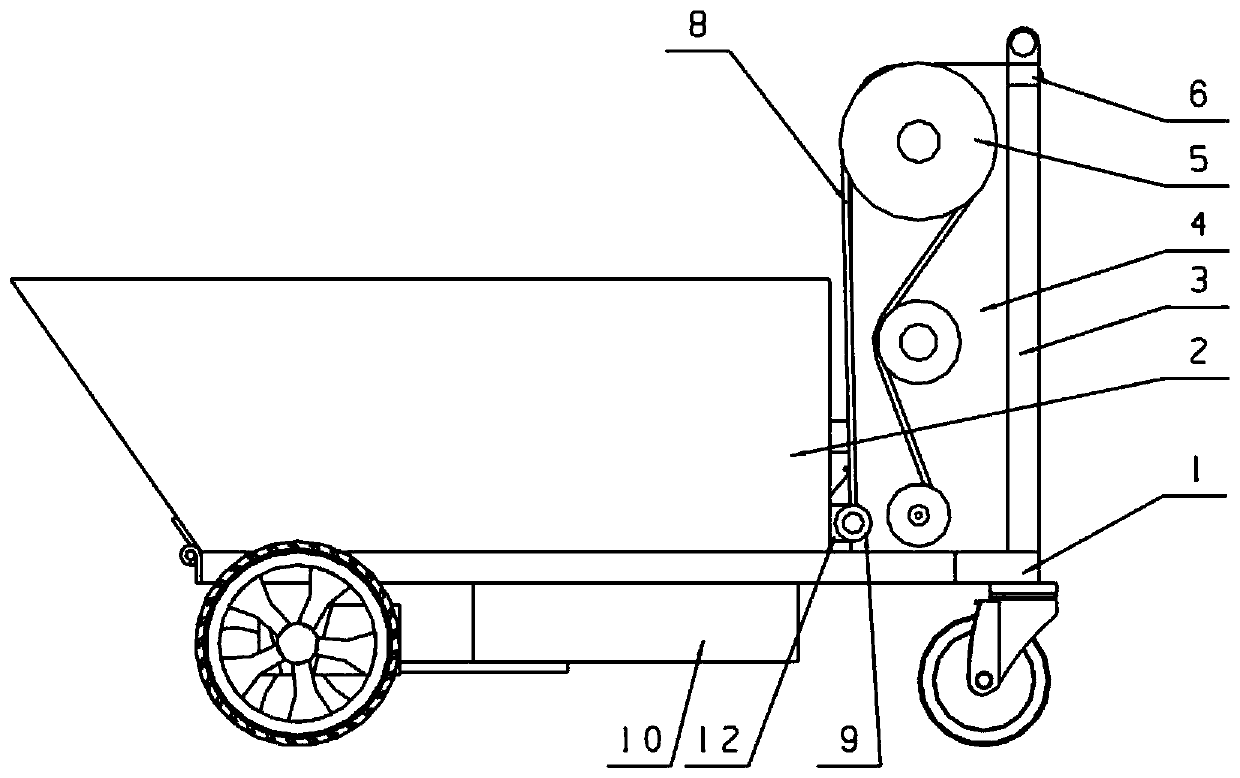

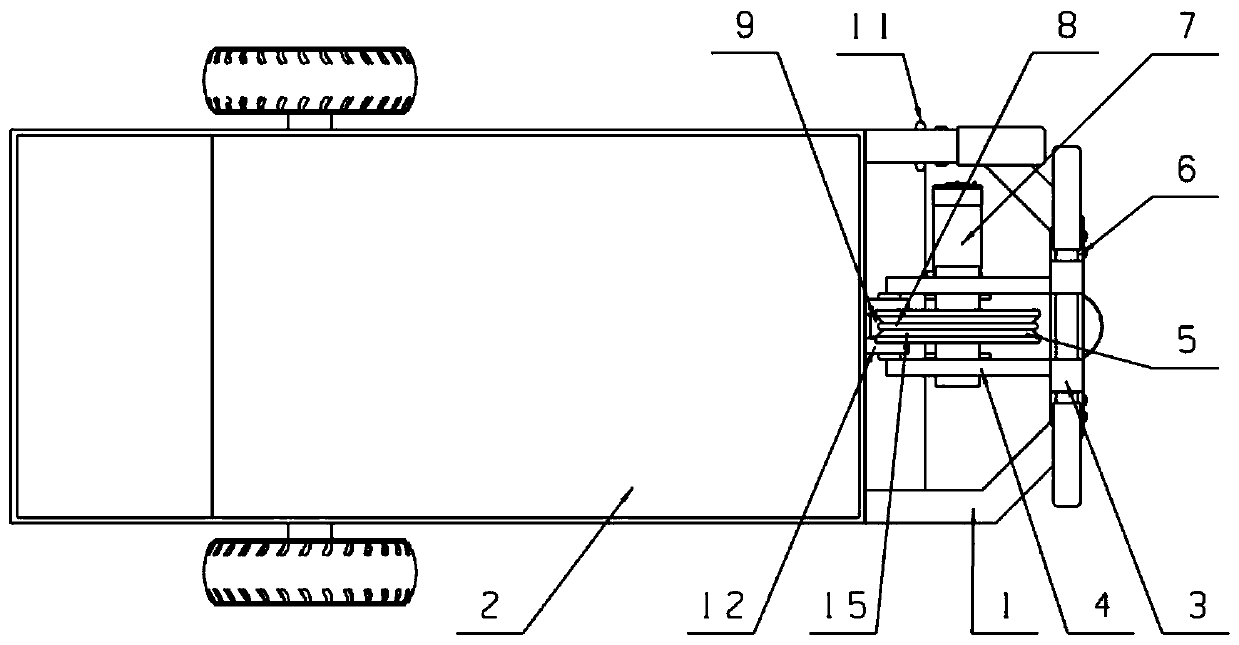

[0025] as attached figure 1 to attach Figure 5 Shown:

[0026] The invention provides an improved bin structure based on a mining transport vehicle, including a vehicle frame 1 and a controller 6; The side slopes are connected, and the middle of the rear side of the vehicle frame 1 is welded with a double-column support frame 3, and the upper end of the support frame 3 is welded with an integrated handle; the lower end of the front right side of the support frame 3 is equipped with a rotating motor 7, and the support frame 3 The front side is equipped with transmission wheel group 5, and the wheel at the bottom of transmission wheel group 5 is connected with rotating motor 7, and transmission wheel group 5 is connected with fixed block 9 at the lower end of feed bin 2 rear end face by cable 8; Described controller 6 is The left and right symmetrical groups are respectively connected to the surfaces on both sides of the support frame 3 through bolts, and the controllers 6 ar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap