Magnetic fluid flywheel for spacecraft

A magnetic fluid and spacecraft technology, which is applied in space navigation equipment, space navigation vehicles, space vehicle guidance devices, etc., can solve undiscovered problems, achieve easy replacement, improve output torque and torque stability, and assemble high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A magnetofluid flywheel for spacecraft includes a conductive fluid ring assembly, a magnetic steel assembly and two electrodes.

[0028] The conductive fluid ring assembly includes a lower sealing cover, a gland, a stem, a fluid shell, and a conductive fluid; the fluid shell is in sealing connection with the lower sealing cover and the gland at the same time, and the stem is simultaneously connected with the lower sealing cover and the gland Sealed connection; the lower sealing cover, the gland, the stem, and the fluid shell jointly form a conductive fluid cavity, and the conductive fluid is located in the conductive fluid cavity. Two electrodes are respectively connected with the stem and the fluid shell.

[0029] Both the lower sealing cover and the gland are made of non-conductive and non-magnetic non-metallic materials. Both the core column and the fluid shell are made of conductive and non-magnetic materials. Both the electrodes and the fluid housing are insulate...

Embodiment 2

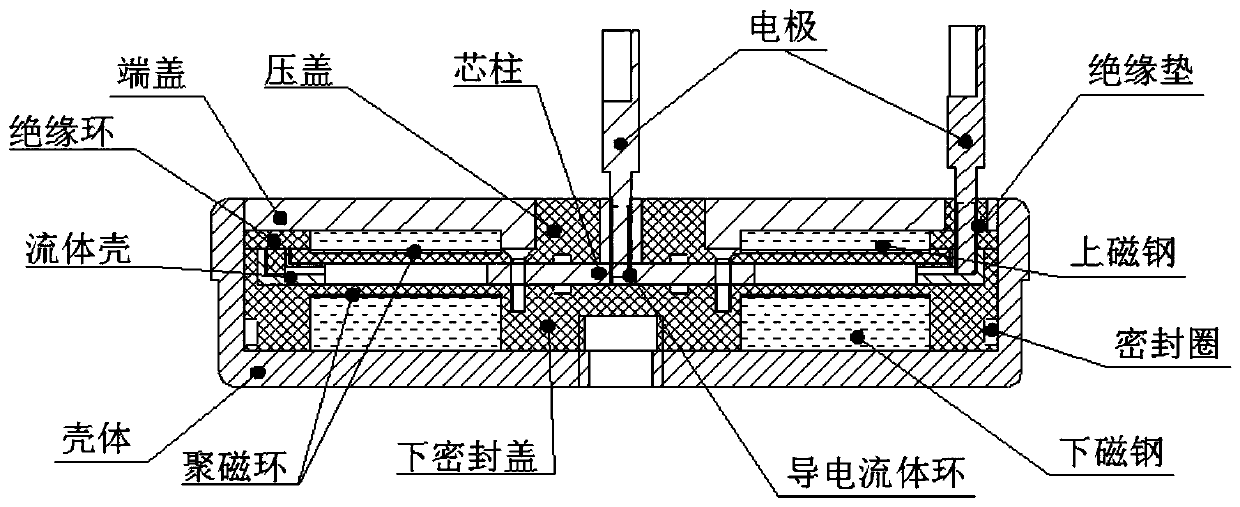

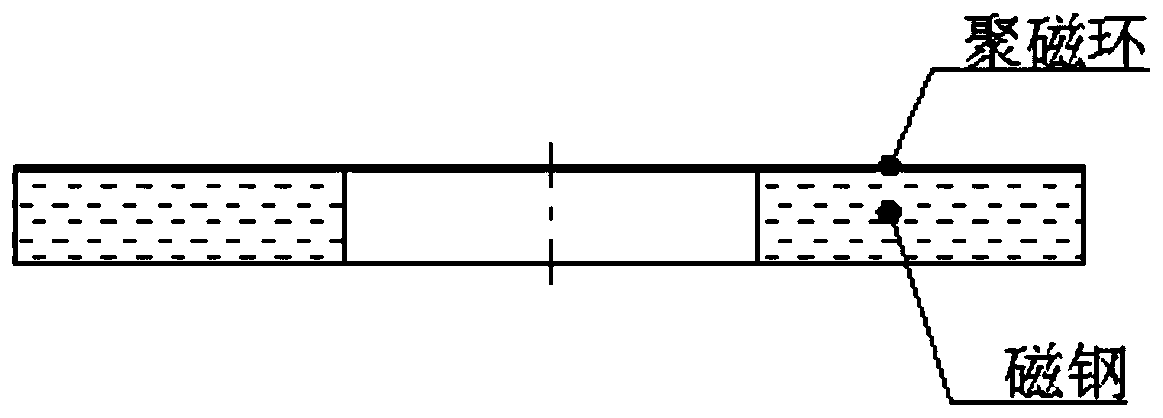

[0034] Such as figure 1 As shown, it is a cross-sectional view of a typical structure of a magnetic fluid flywheel in this embodiment, that is, the basic form of the present invention, including a conductive fluid ring assembly, a magnetic circuit assembly and electrodes.

[0035] The rotation of the conductive fluid in the conductive fluid ring assembly can generate torque and angular momentum; the magnetic steel assembly is used to form the magnetic field used for the rotation of the conductive fluid; The inner and outer walls of the conductive fluid cavity form a potential difference, and the movement of charges causes the conductive fluid to rotate under force.

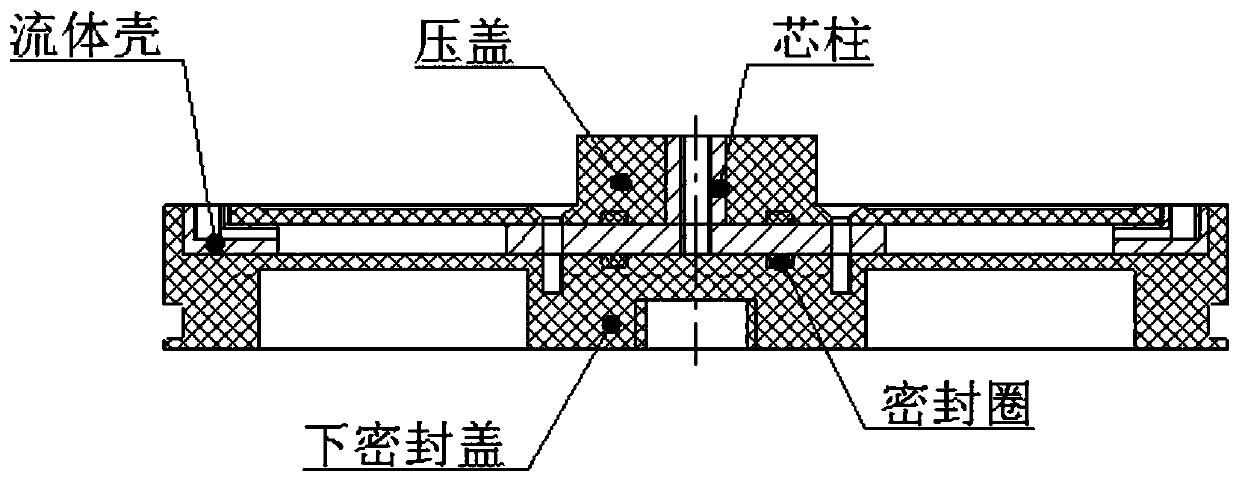

[0036] The conductive fluid ring assembly includes a lower sealing cover, a stem, a fluid shell, a gland, and a conductive fluid, such as figure 2 As shown, a conductive fluid cavity is formed between the lower sealing cover and the gland by the stem and the fluid shell, and the conductive fluid is sealed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com