A kind of synthetic method of calcium octanoate

A technology of calcium n-octanoate and a synthesis method, which is applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, preparation of carboxylate salts, etc., can solve problems such as limitations, and achieve simple operation, easy realization, and simple reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

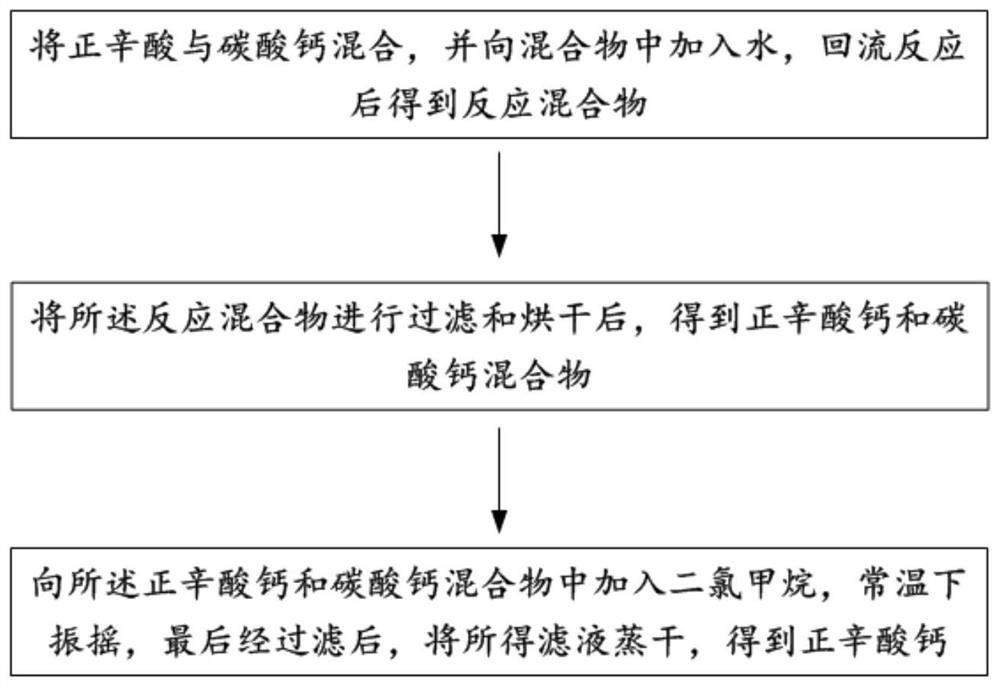

[0018] Such as figure 1 , figure 1 It is process flow diagram of the present invention; Present embodiment provides a kind of synthetic method of calcium n-octoate, comprises the following steps:

[0019] (1) N-octanoic acid is mixed with calcium carbonate, and water is added in the mixture, and reaction mixture is obtained after reflux reaction;

[0020] (2) after above-mentioned reaction mixture is filtered and dried, obtain n-octoate calcium and calcium carbonate mixture;

[0021] (3) Add dichloromethane to the mixture of calcium n-octoate and calcium carbonate, shake at room temperature for 30 minutes, and finally filter and evaporate the resulting filtrate to dryness to obtain calcium n-octoate.

[0022] The advantages of the synthetic method of calcium octanoate in the present invention are as follows: Calcium carbonate is an inorganic compound, which is a common substance on the earth, exists in rocks such as aragonite, calcite, chalk, limestone, marble, travertine, a...

Embodiment 1

[0026] Embodiment 1 of the present invention provides a kind of synthetic method of calcium octanoate, comprises the following steps:

[0027] Add n-octanoic acid, calcium carbonate, water and zeolite into a three-necked flask, wherein the mol ratio of n-octanoic acid to calcium carbonate is 1:0.7, and the mol ratio of n-octanoic acid to water is 1:0.7; subsequently, heat up to 80° C., reacting for 5 hours; after the reaction, the above reaction mixture was filtered, dried, and separated to obtain calcium n-octoate, and the yield of obtained calcium n-octoate was 77.1%.

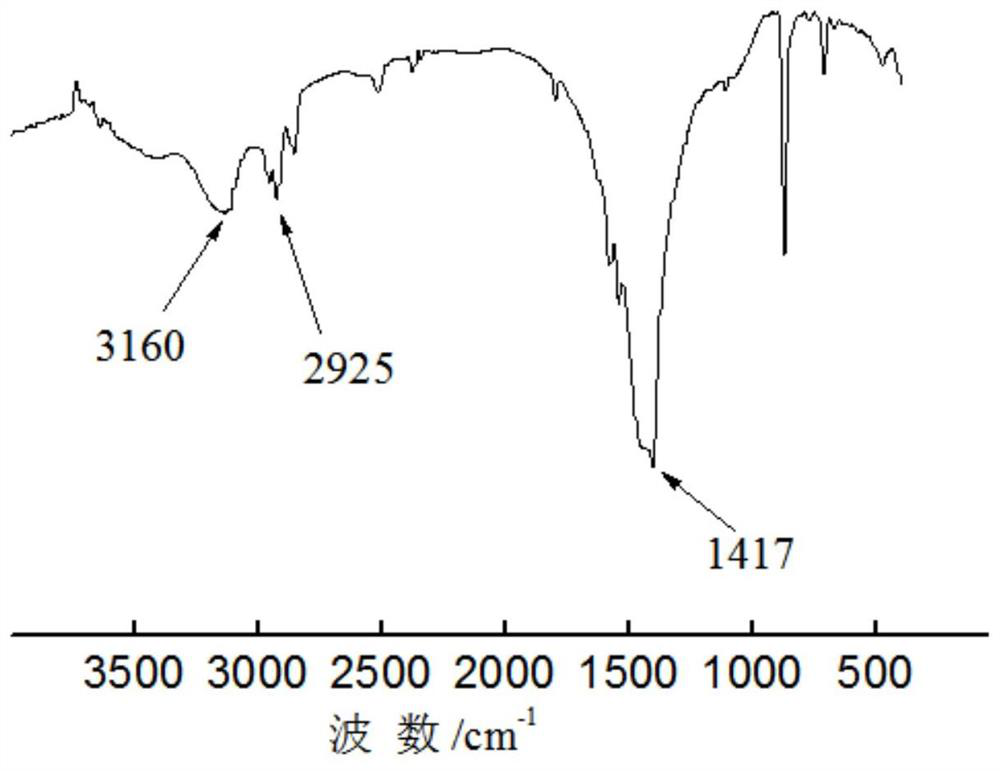

[0028] Such as figure 2 , figure 2 It is the infrared spectrogram of calcium n-octoate in embodiment 1, known from the infrared spectrogram, 1578-1540cm -1 and 1417cm -1 The strong peaks of the carboxyl group are the antisymmetric stretching vibration peak and the symmetrical stretching vibration peak, which belong to COO - characteristics, indicating that there is a carboxyl group COO in the compound ...

Embodiment 2

[0030] Embodiment 2 of the present invention provides a kind of synthetic method of calcium octanoate, comprises the following steps:

[0031] Add n-octanoic acid, calcium carbonate, water and zeolite into a three-necked flask, wherein the molar ratio of n-octanoic acid to calcium carbonate is 1:1, and the molar ratio of n-octanoic acid to water is 1:0.7; subsequently, heat up to 200° C., reacting for 5 hours; after the reaction, the above reaction mixture was filtered, dried, and separated to obtain calcium n-octoate, and the yield of obtained calcium n-octoate was 98.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com