Rocket solid propellant flattener (No.4)

A solid and rocket technology, applied in the aerospace field, can solve problems such as risk and responsibility, quality difficulty, and quality rockets that cannot go to the sky.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

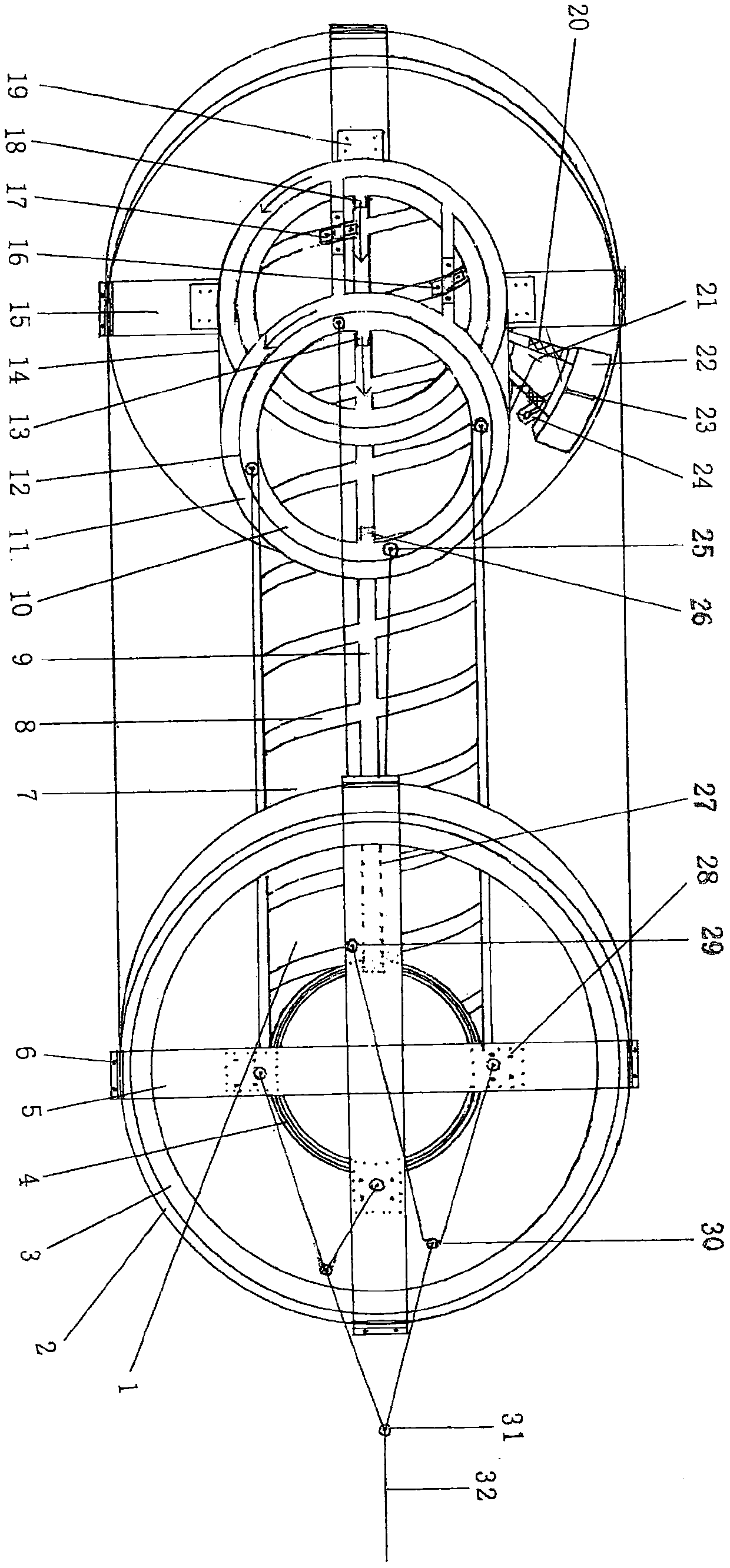

[0010] exist figure 1 In the middle, the rocket solid powder leveler 1, the rocket outer barrel 2, the solid gunpowder in the rocket barrel 3, the middle barrel shaft 4, the connecting piece 28 is connected to the cross 5, the fixing screw 6 is fixed on the side of the rocket outer barrel mouth 2, the middle barrel shaft 4. It is better to use light hard alloy. The outer layer is made of plastic layer 7 to make screw groove 8 and straight groove 9. Use plastic as material to avoid gunpowder friction and ignition. The structure plays a variety of functions and movements. There are two sliding heads 13 in the two inner rings 10, which are arranged in the straight groove 9 to move flexibly. Fifteen large diameter middle barrel shaft 4 plus the inner ring and the outer barrel diameter are 45 to 50% of the diameter of the rocket inner barrel, reducing the load on the middle barrel shaft 4, and the outer ring barrel 11 has a large enough diameter The connected planer 22 increases t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com