Excavation method based on local section blasting and heading machine excavation

A technology of roadheader and section, which is applied in blasting, earthmoving, mining equipment, etc., can solve the problems of low driving speed and footage damage, and achieve the effect of high driving efficiency, avoiding defects and controlling surrounding rock damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

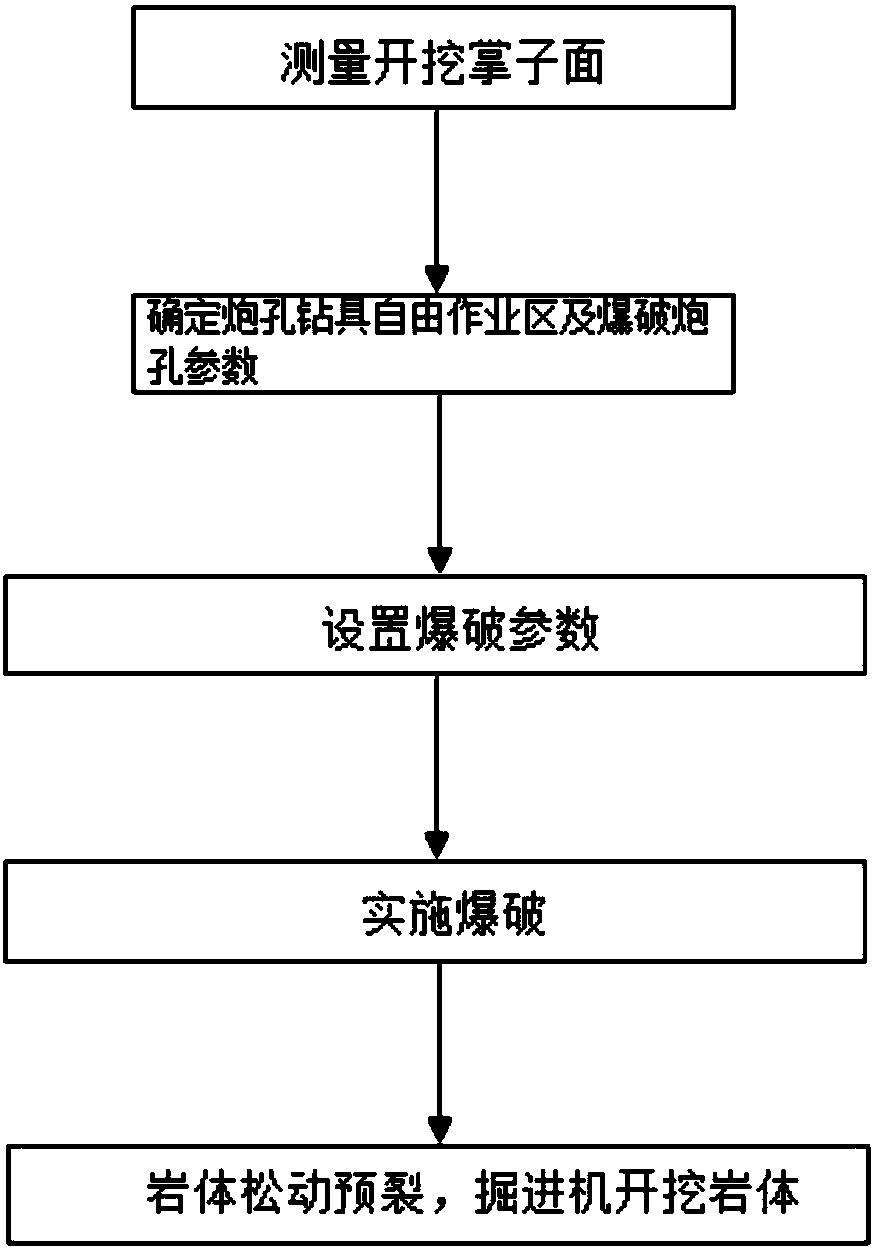

[0029] like Figure 1-3 Shown, a kind of excavation method based on local section blasting and roadheader excavation is characterized in that: the method comprises the following steps:

[0030] Step 1: Measure the excavation face;

[0031] Step 2: Determine the free operation area of the blast hole drilling tool and the parameters of the blast hole;

[0032] Step 3: Set blasting parameters;

[0033] Step 4: implement blasting;

[0034] Step 5: The rock mass is loosened and pre-cracked, and the roadheader excavates the rock mass.

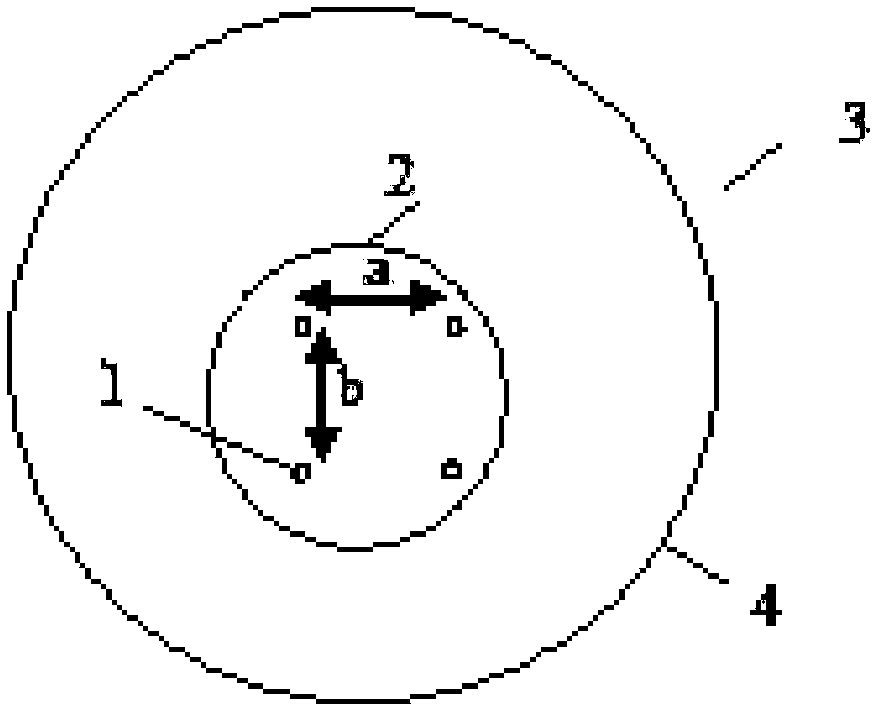

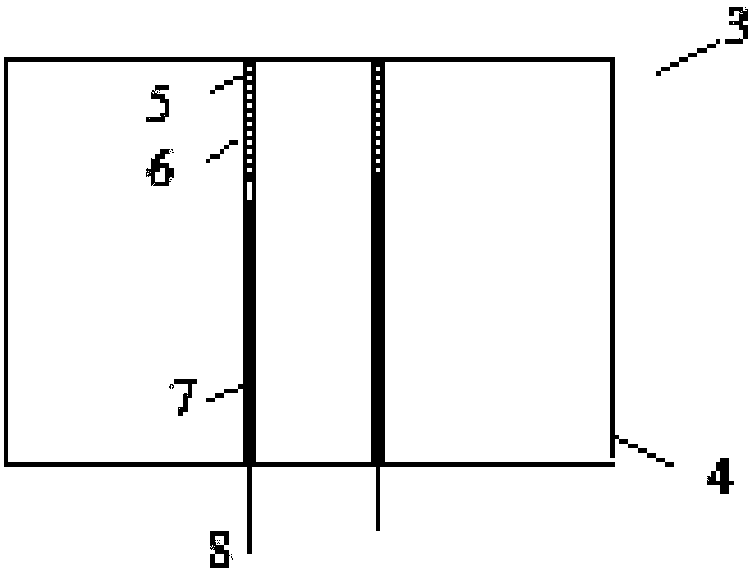

[0035] The first step: measuring the excavation face includes: first measuring the excavation face of the roadway. This excavation method is suitable for various excavation sections. Generally, it is a circular contour area. For hard rock excavation, it is based on the theoretical basis that blasting can impro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com