Non-uniform electric loss metamaterial and preparation method thereof

An electric loss and non-uniform technology, applied in the field of metamaterials, can solve the problems that continuous and arbitrary changes cannot be achieved, and the position accuracy of non-uniform electric loss microstructures is difficult to guarantee.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

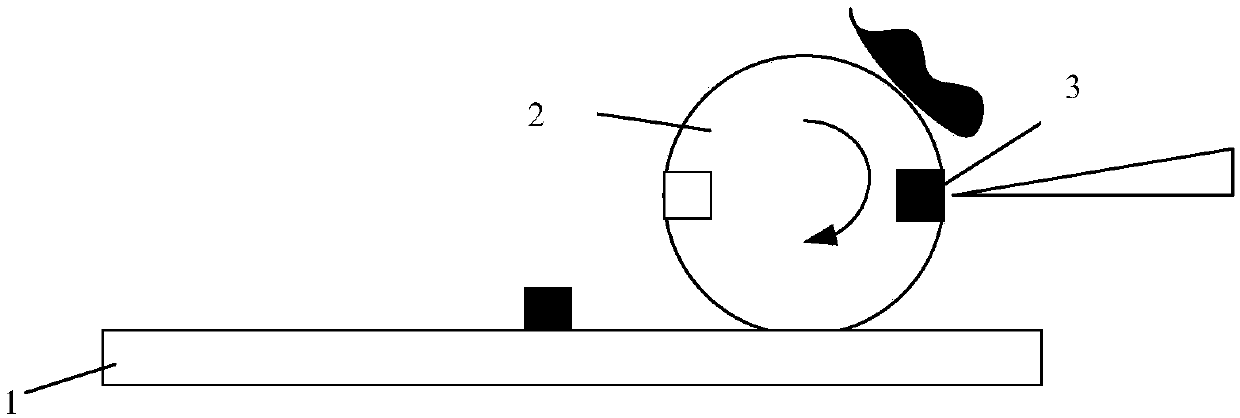

[0028] First, prepare a drum-type steel mold (2M in diameter, 1M in length). Two microgrooves are etched on the surface of the steel mold with EDM. Then, pour the carbon slurry on the steel mold (roller), control the gap between the scraper and the roller, and scrape off the excess slurry outside the groove. After that, the carbon slurry in the microgroove is transferred to the fiber membrane by pressing the roller and the fiber membrane. The thickness of the slurry on the fiber membrane is equal to the depth of the microgroove on the roller at the corresponding position, that is, the non-uniform electrical loss Super material.

Embodiment 2

[0030] First prepare a drum-type steel mold (diameter 2M, length 1M), the surface of the steel mold surface is etched with two microgrooves by electric spark, the width of the first groove is 50μm, and the depth is 30μm~50μm Gradient changes; the other The width of the groove is 40 μm, and the depth varies from 20 μm to 40 μm in a gradient. Then, pour the silver paste on the steel mold (roller), control the gap between the scraper and the roller, and scrape off the excess paste outside the groove. Afterwards, the carbon slurry in the microgroove is transferred to the fiber membrane through the pressing of the roller and the fiber membrane. The thickness of the slurry on the fiber membrane is equal to the depth of the microgroove on the roller at the corresponding position, that is, a non-uniform electric current is obtained. loss of metamaterials.

Embodiment 3

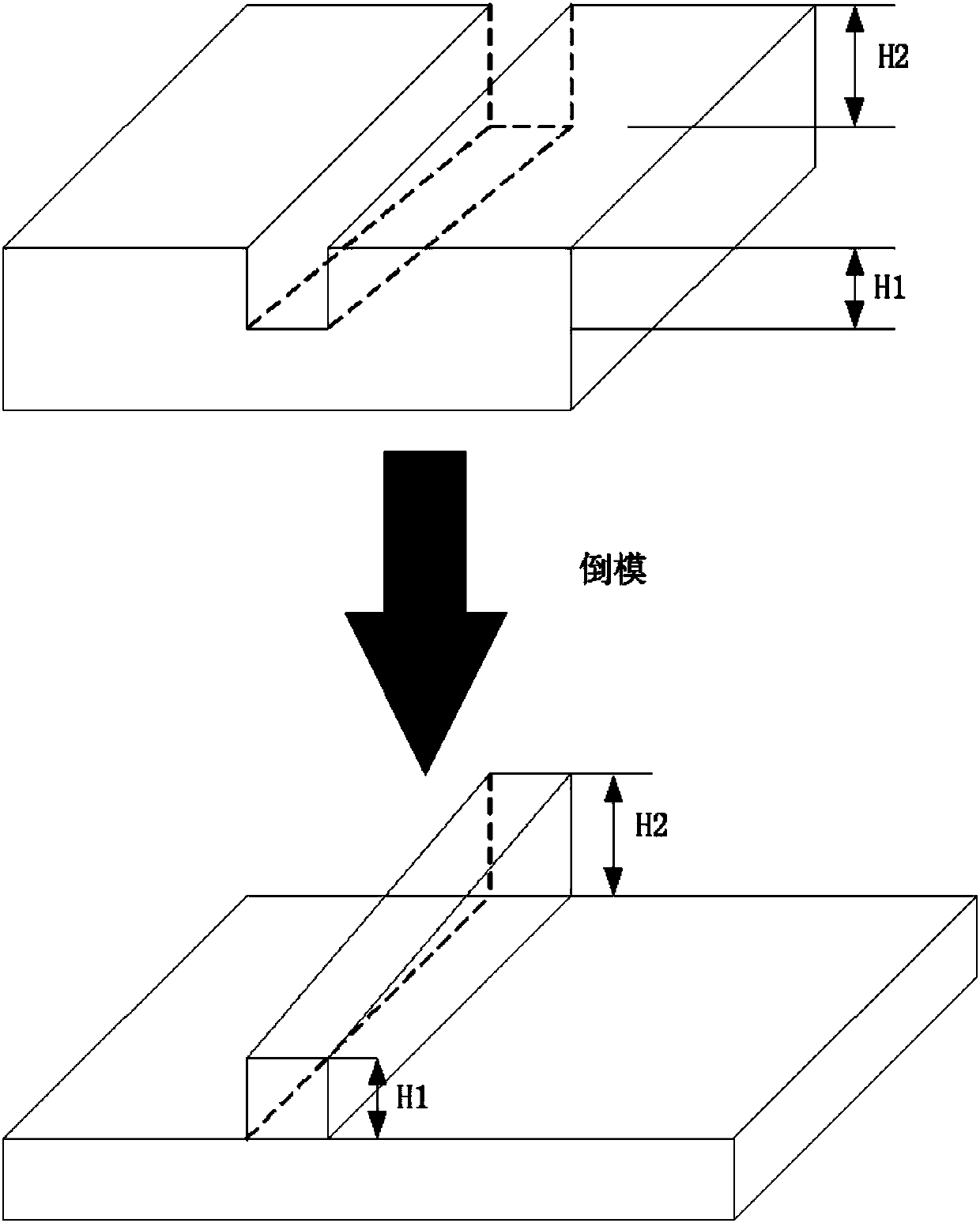

[0032] Prepare a mold of a flat plate, the surface of the mold is grooved, the depth of the groove is the same as the thickness of the microstructure, the depth of one end of the groove is 30 μm, and the depth of the other end is 60 μm. The copper paste is filled into the slot by scraping with a scraper. Afterwards, the polymer film is pasted on the upper surface of the mold, cured and demoulded, and microstructure patterns with different thicknesses are obtained, that is, non-uniform electrical loss metamaterials are obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com