Laser modules for vehicle headlights

A technology of laser module and optical module, which is applied in the direction of lasers, headlights, vehicle parts, etc., and can solve the problems of complex structure, cost and time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

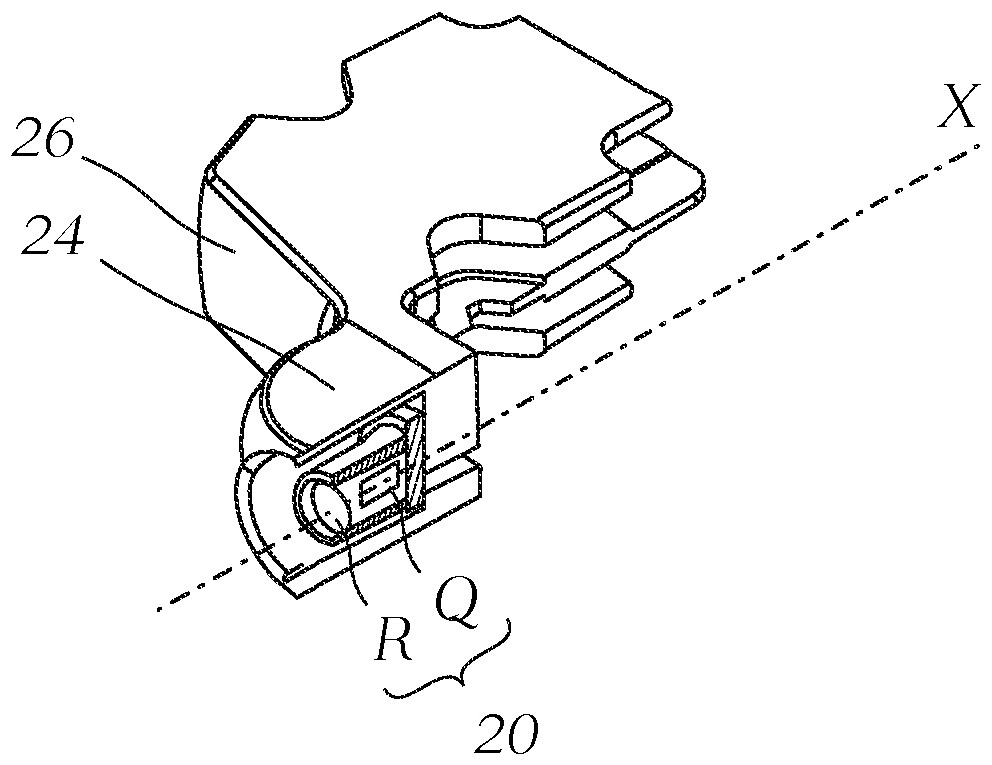

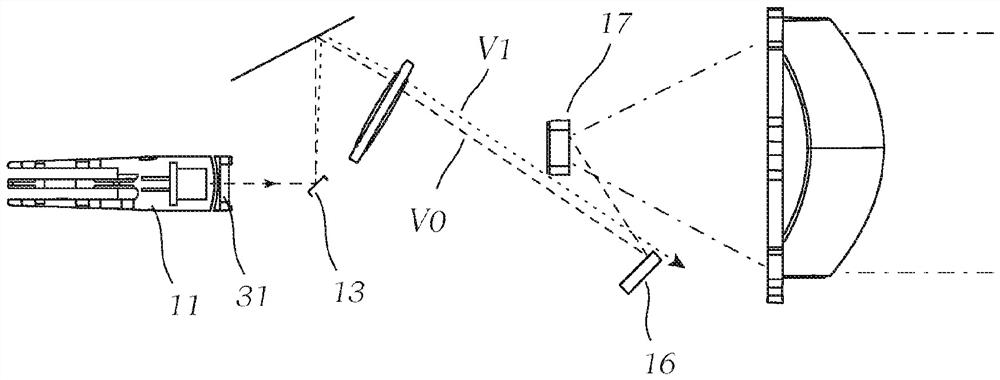

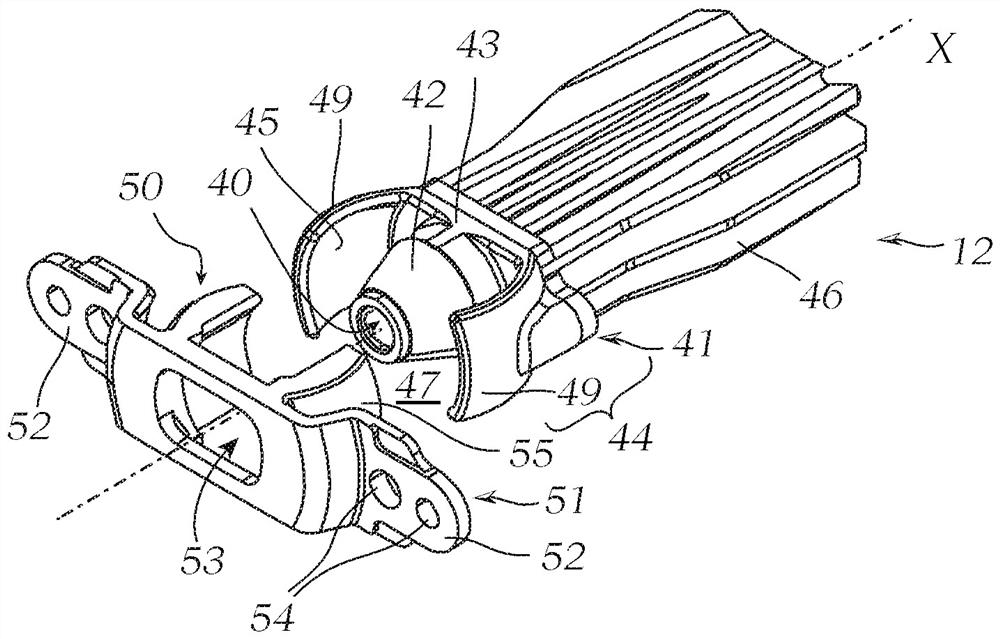

[0034] Figures 1 to 7 A first exemplary embodiment of the invention, a light module 10 for a motor vehicle headlight, is shown. exist figure 1 The light module 10 is shown with an open housing 19 , whereby an overview of the important optical components of the light module 10 is visible. figure 2 The optical components of the light module 10 and the optical paths of the plurality of laser beams, which are defined by these components, are shown.

[0035] The light module 10 contains a certain number of laser modules 11 (eg two to five, more generally one to ten or more, depending on the chosen implementation variant), as in particular in figure 2 as can be seen in . Each laser module 11 contains a laser light source Q ( Figure 5 ), the laser light source is in the form of a laser diode in the example shown; however, other known types of laser light sources can be used in a corresponding manner. For example, the laser modules 11 are arranged in a linear arrangement in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com