Shaping tool, method for producing an edge on a component, and method for producing a shaping tool of this kind

A technology for forming molds and forming parts, applied in vehicle parts, transportation and packaging, etc., can solve problems such as thinning of body metal plate parts, and achieve the effect of long service life and low wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Identical or functionally identical elements have the same reference symbols in the figures.

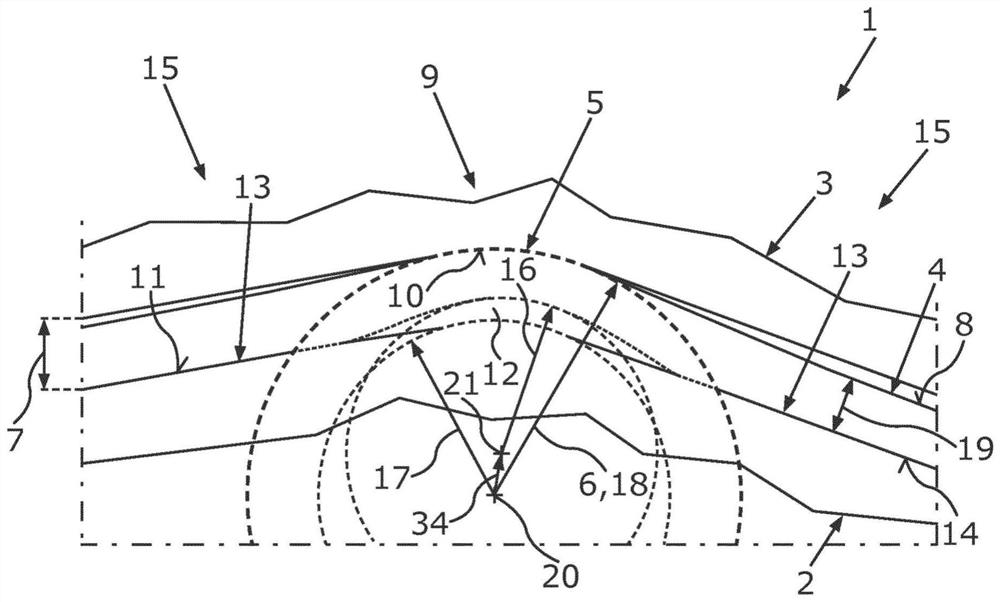

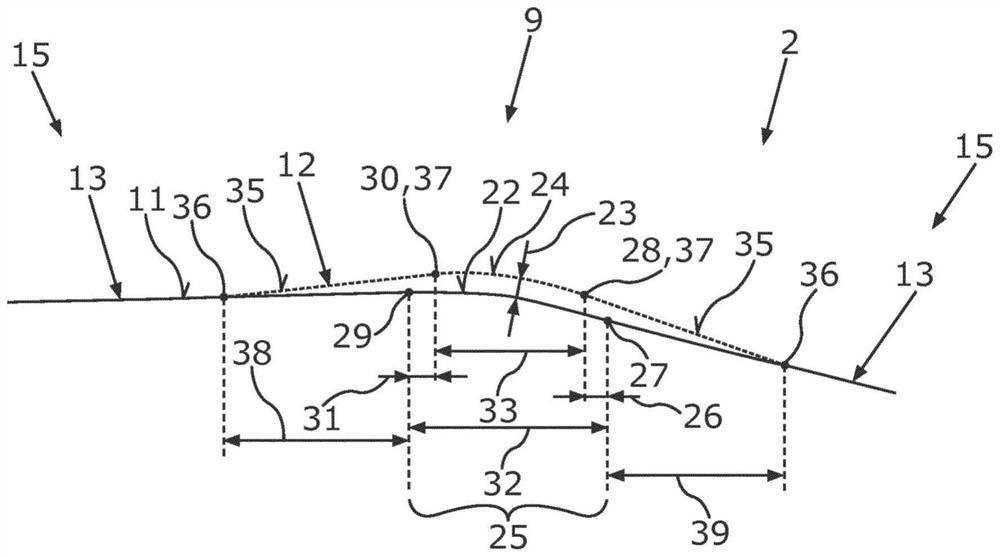

[0032] figure 1 A forming tool 1 is shown schematically, which comprises a first forming part 2 , in particular formed as a punch, and a second forming part 3 , in particular formed as a die. Between the first and the second profiled part 2 , 3 there is a component 4 which is to be given an edge 5 by means of the profiled tool 1 . Edge 5 is a curvature with a particularly small radius, such as edge radius 6 . If the component 4 is a skin component of a motor vehicle, the appearance of the motor vehicle can be given a special, eg sporty character, by means of the edge 5 . This means that the edge 5 can be a so-called characteristic edge. Furthermore, the edge 5 can have a technical function, for example as a flow guide for water flowing along the outer shell of the motor vehicle. Such a characteristic edge can extend over a plurality of adjacent shell components on the skin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com